Washing machine with drying device

A drying device and washing machine technology, applied in the field of washing machines, can solve problems such as unsatisfactory drying effect, and achieve the effects of improving drying effect and removing moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

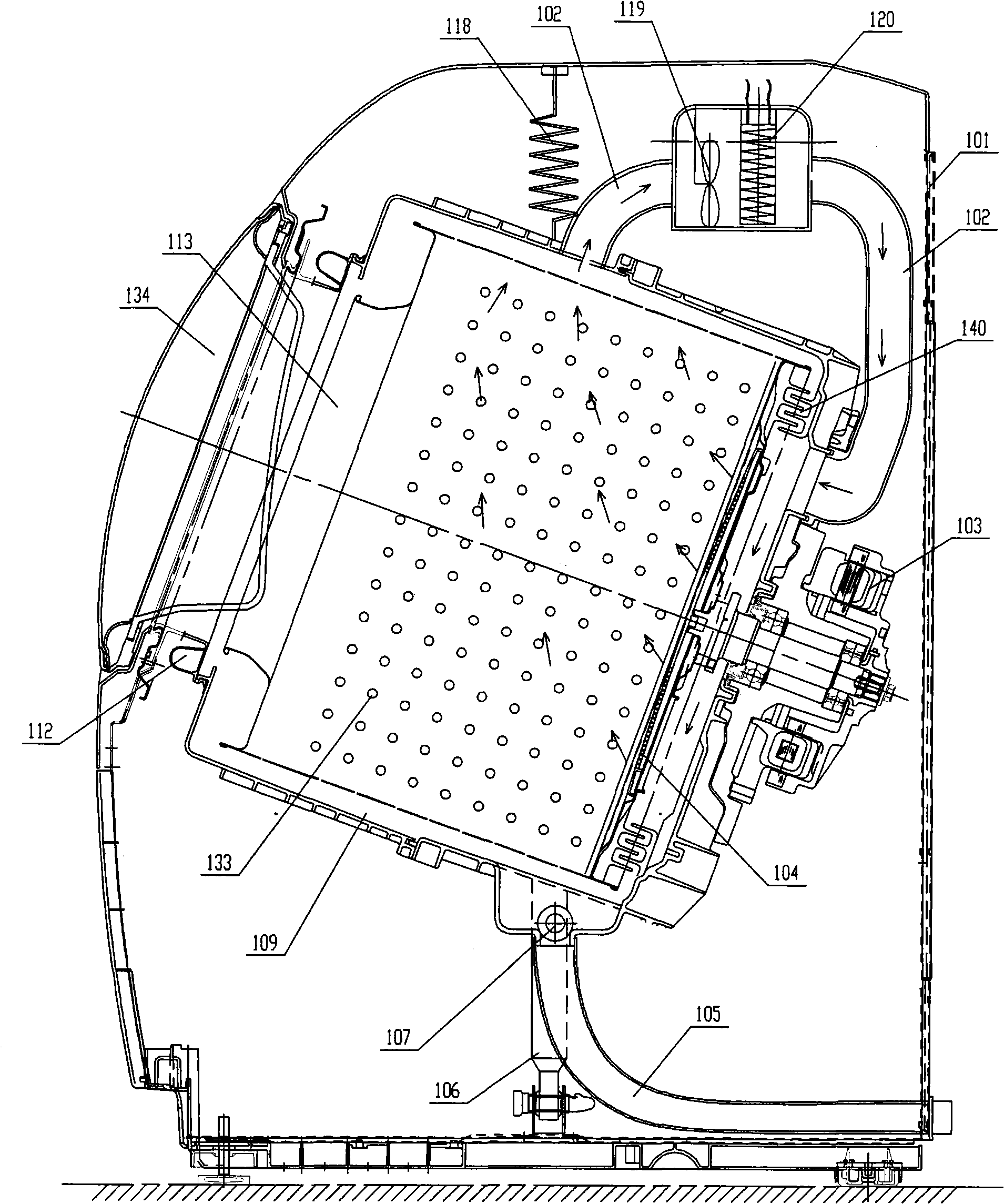

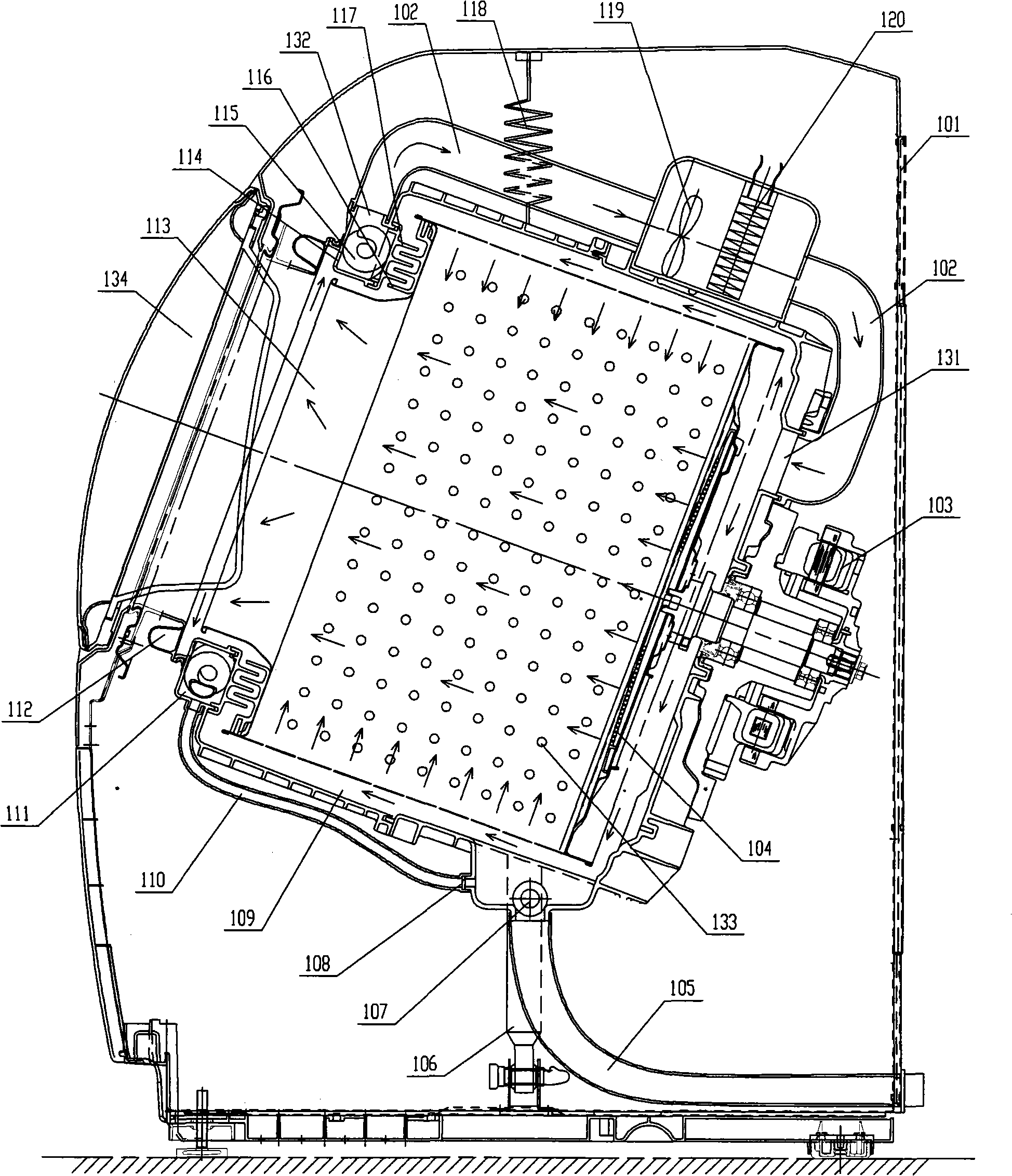

[0031] refer to figure 2 , a washing machine with a drying device, which mainly includes: a washing machine shell 101, a drying pipe 102, a driving motor 103, a drain pipe 105, a shock absorber 106, a drain valve 107, a water bucket 109, a condensate pipe 110, an annular channel 111, Window sealing ring 112, machine door 134, drum 113, windshield 116, suspension spring 118, blower fan 119, heating device 120.

[0032] Said water tub 109 is elastically arranged inside the washing machine shell 101 through suspension springs 118 and shock absorbers 106, and a hot air injection port 131 is provided on its rear end surface, and a window sealing ring 112 and a machine door are provided outside the front opening. 134, the inner surface of its front end is provided with multi-turn ribs 117 protruding inward.

[0033] The drum 113 is disposed inside the tub 109 and driven to rotate by the driving motor 103 . The clothes are stored inside the drum 113, and the clothes are washed, de...

Embodiment 2

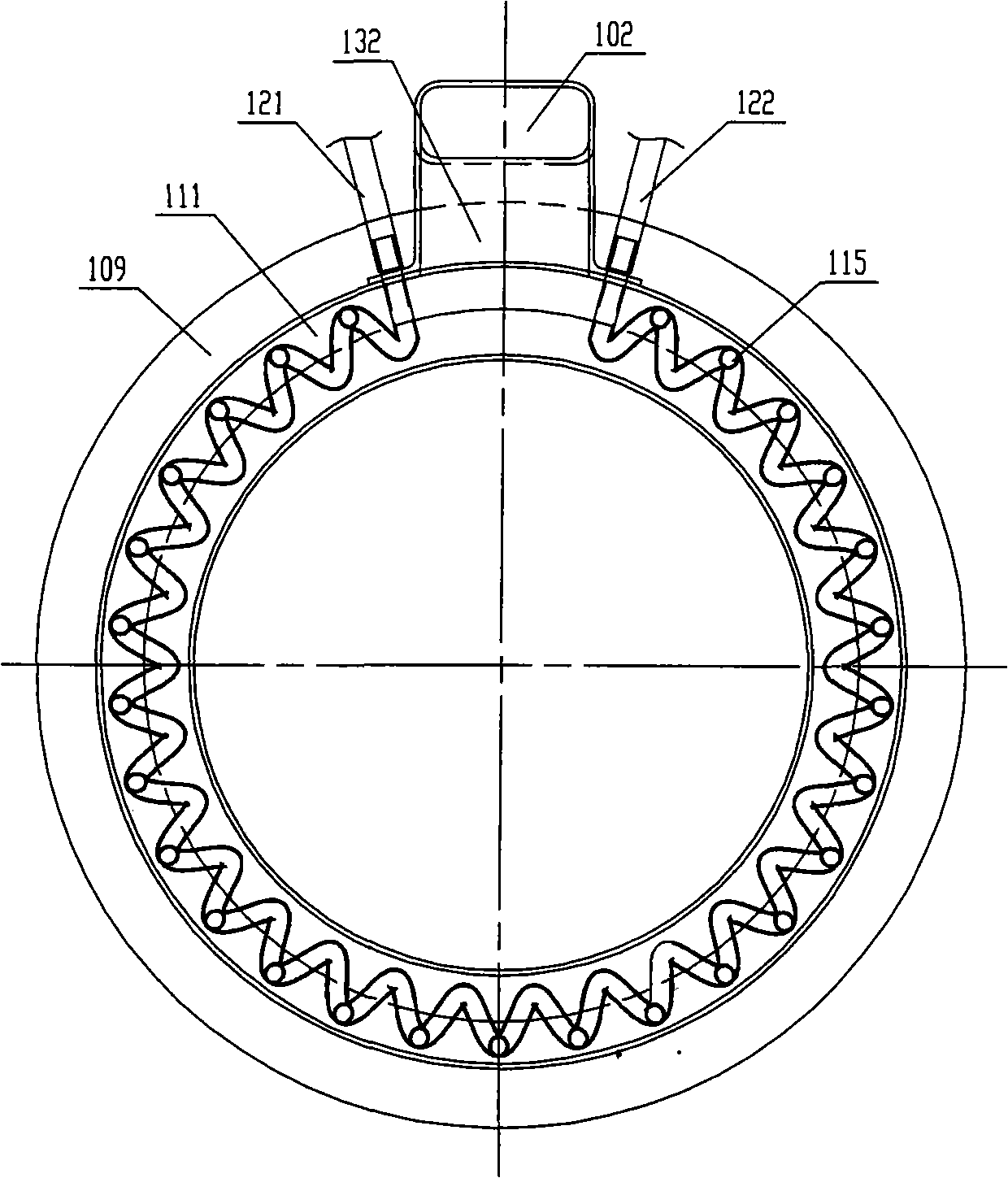

[0042] refer to Figure 4 , 5 , The difference between this embodiment and Embodiment 1 mainly lies in the structure of the dehumidification device. The dehumidification device adopts a water-cooling channel 126 with cooling fins 125 arranged in a ring. The cooling fins 125 and the suction holes 114 are distributed on the water-cooling channel at intervals. A port 123 (or 124) of the water-cooling channel 126 is connected to the water injection valve. Another port 124 (or 123) communicates with the drainpipe 105, and the cold water injected from the water-cooling runner 126-port 123 (or 124) exchanges heat with the air-flow in the annular channel 111, and then flows from the other port 124 (or 124) 123) Discharge. The cooling fins 125 on the water-cooling channel 126 are arranged in an arc shape, and are provided with a plurality of small holes to reduce resistance to airflow. The water-cooling channel 126 and the heat sink 125 can be made of metal materials with good therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com