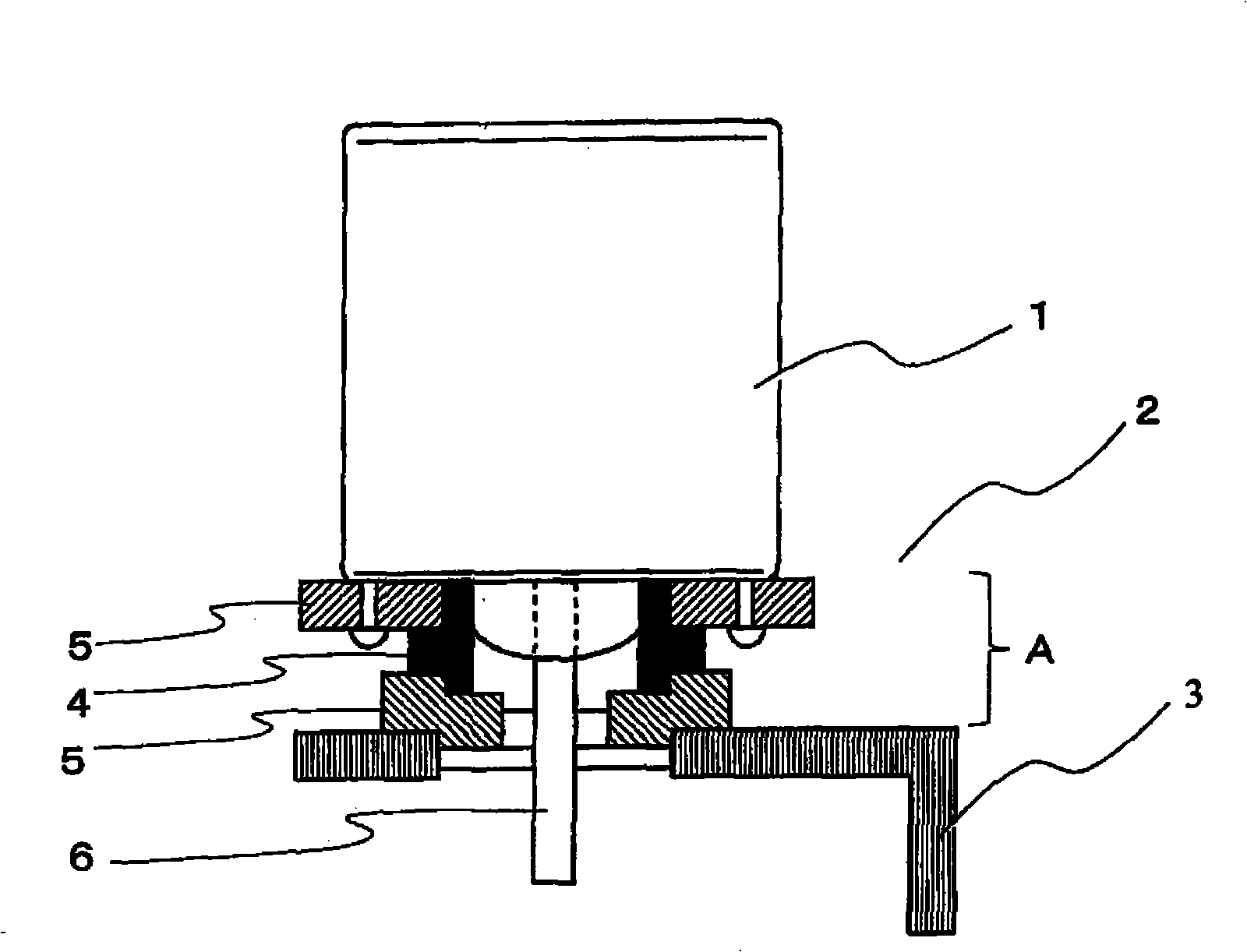

Vibration damping rubber and motor fixing mount

A technology of anti-vibration rubber and engine, which is applied in the direction of non-rotational vibration suppression, etc., can solve the problems of weak strength and degassing of silicone rubber, and achieve the effects of improved thermal conductivity, material strength and anti-vibration performance, and good mixing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072]

[0073] Polymer: NBR rubber

[0074] (Nipol DN3350 manufactured by Nippon Zeon Company;

[0075] Combined AN amount 33%, ML central value 50) 100 parts by weight

[0076] Reinforcing agent: Precipitated silica (Nipsil VN3 manufactured by Tosoh-Sirica Industry Co., Ltd.)

[0077] 14 parts by weight

[0078] : Graphite (particle size 5μm)

[0079] (GRAPHITE A-0 manufactured by Nidec Ibbon Co., Ltd.) 35 parts by weight

[0080] : Graphite (particle size 10μm)

[0081] (GRAPHITE G-6S produced by Chuetsu Black Lead Industry Co., Ltd.) 35 parts by weight

[0082] : Acetylene carbon black (DENKA BLACK granule manufactured by Denki Kagaku Kogyo Co., Ltd.)

[0083] 35 parts by weight

[0084] Vulcanization accelerator: Zinc oxide (1 type of zinc oxide manufactured by SAKAI CHEMICAL INDUSTRY Co., Ltd.) 5 parts by weight

[0085] : Stearic acid (TST stearic acid manufactured by Miy...

Embodiment 2

[0120] A rubber sample was prepared in the same manner as in Example 1 except that the graphite in Example 1 was changed from A-0 and G-6S to only 70 parts by weight of G-6S, and an evaluation test was performed.

Embodiment 3

[0122]Change the graphite of embodiment 1 into the G-6S that only adds 70 parts by weight with A-0 and G-6S, and add the acetylene carbon black of 65 parts by weight, and make the rubber sample in the same way as embodiment 1 , to carry out the evaluation test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com