Manganese dioxide mesoporous material and method of preparing the same

A manganese dioxide mesoporous and manganese dioxide technology, applied in the field of materials, can solve the problems of application limitations and less performance research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Preparation of Na-type layered manganese dioxide

[0043] 200mL concentration of 0.6mol / L NaOH and concentration of 1.2mol / L H 2 o 2 The mixed solution was quickly added to 100mL with a concentration of 0.4mol / LMn(NO 3 ) 2 solution, namely Mn 2+ with OH - The molar ratio is 1:3, Mn 2+ with H 2 o 2 The molar ratio is 1:6, vigorously stirred and reacted for 30 minutes, filtered, and the filter cake was transferred to a 100mL polytetrafluoroethylene cup, and 40mL of NaOH solution with a concentration of 2mol / L was added, that is, MnO 2 with OH - The molar ratio was 1:2, and it was stirred to form a paste. The polytetrafluoroethylene cup was sealed in a hydrothermal kettle, and hydrothermally treated at 160°C for 15 hours. After the hydrothermal kettle is naturally cooled to room temperature, the kettle is opened for suction filtration, and the filter cake is washed with deionized water until the pH value of the filtrate is 7-8. The resulting precipitate was dr...

Embodiment 2

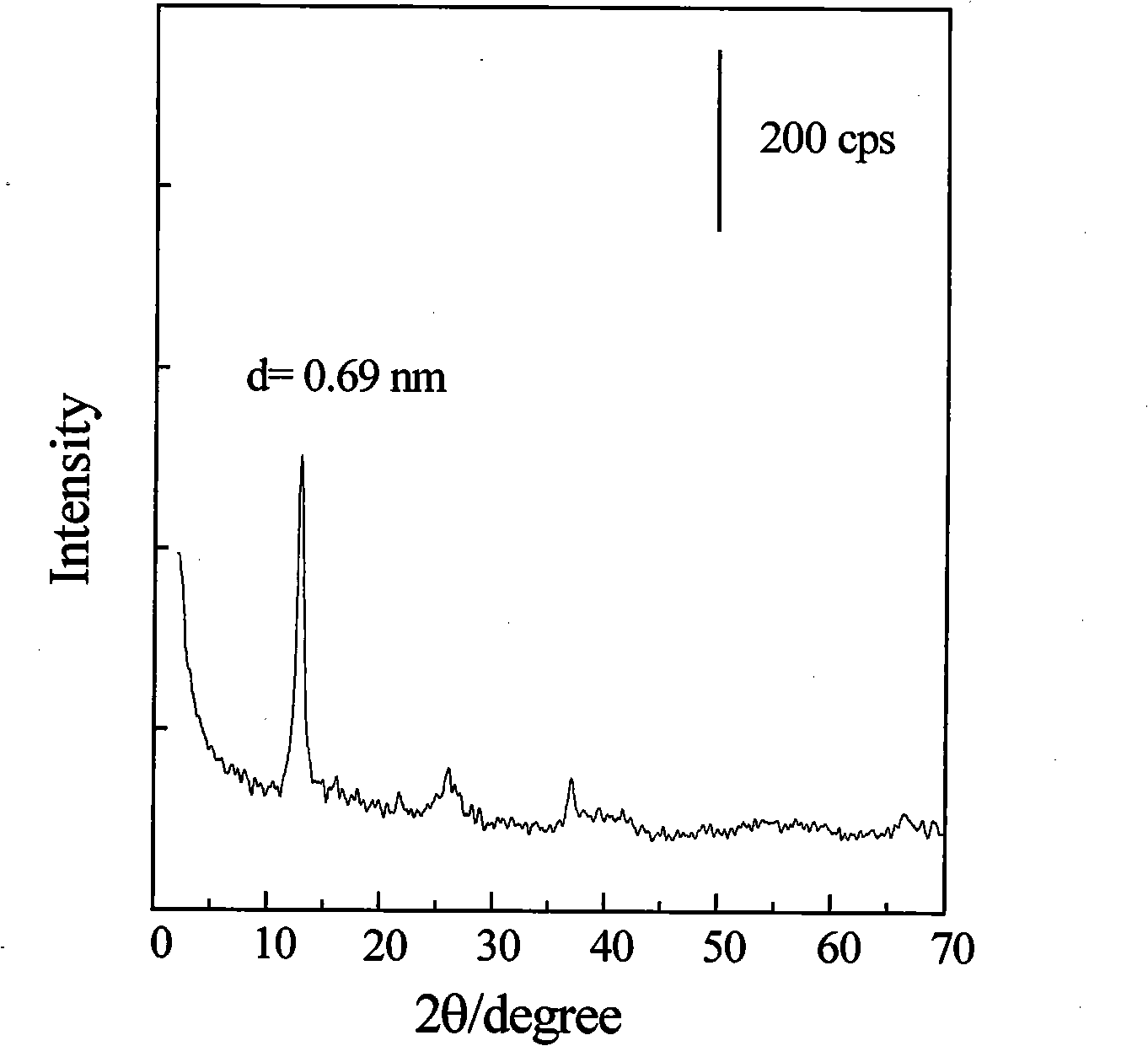

[0062] In step 4 of the assembly reaction process of manganese dioxide nano-layer and divalent manganese ion, take the stripped manganese dioxide nano-layer suspension and add it to deionized water to form a manganese dioxide nano-layer with a concentration of 0.02mol / L Sol solution 200mL, take 40mL concentration and be 0.1mol / L manganese nitrate aqueous solution, the Mn in manganese nitrate 2+ The molar ratio of peeling off the manganese dioxide nano-layer is 1: 1, the manganese dioxide nano-layer sol solution and the manganese nitrate solution are mixed, the resulting mixed suspension is stirred and reacted at room temperature for 4 hours, filtered, and washed with deionized water for 3-3 hours. 4 times, remove the divalent manganese ions adsorbed on the precipitation surface, and dry at room temperature for 24 hours to obtain layered manganese oxide intercalated with divalent manganese ions.

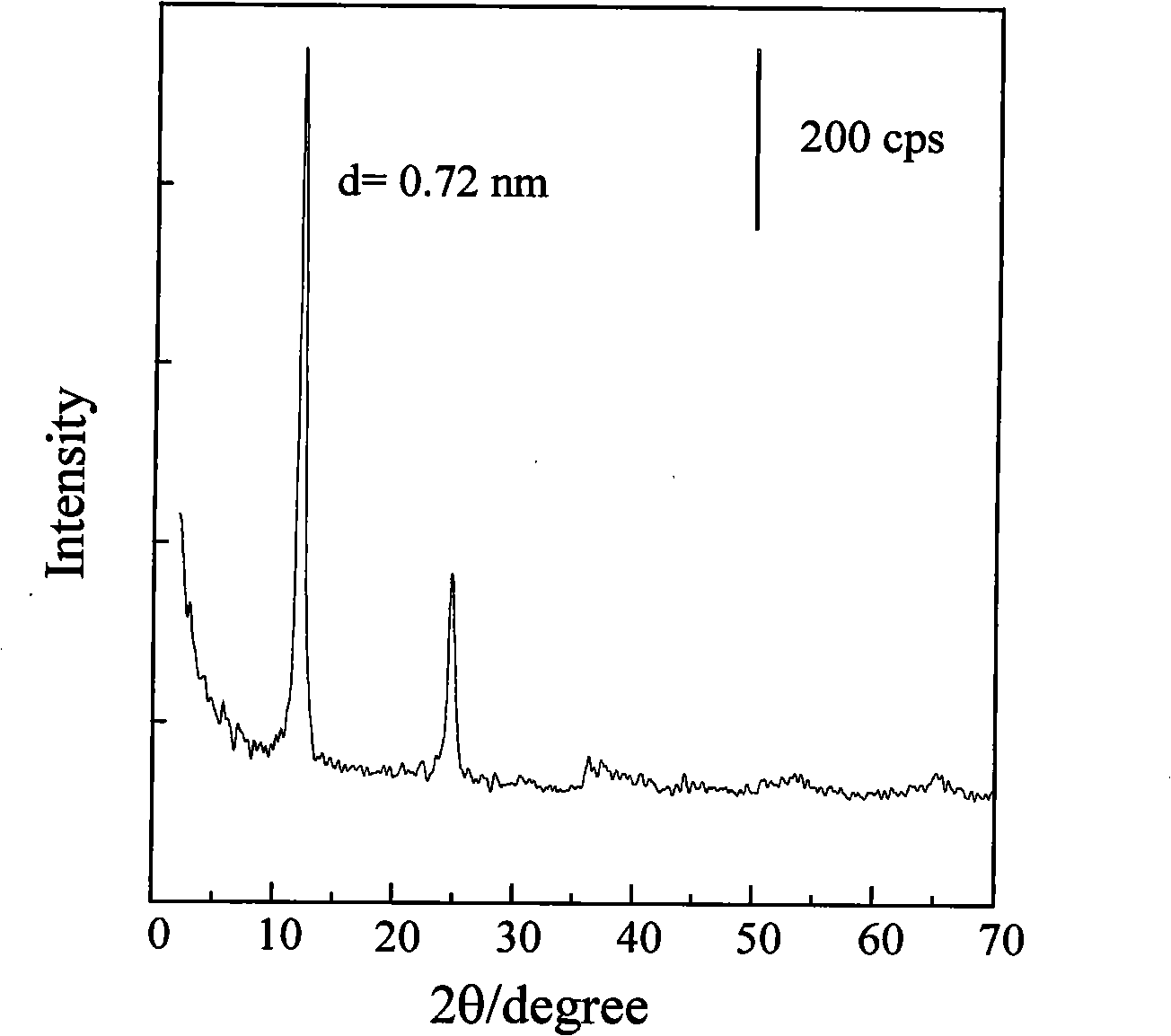

[0063] In the oxidation process step 5 of the layered manganese oxide intercalate...

Embodiment 3

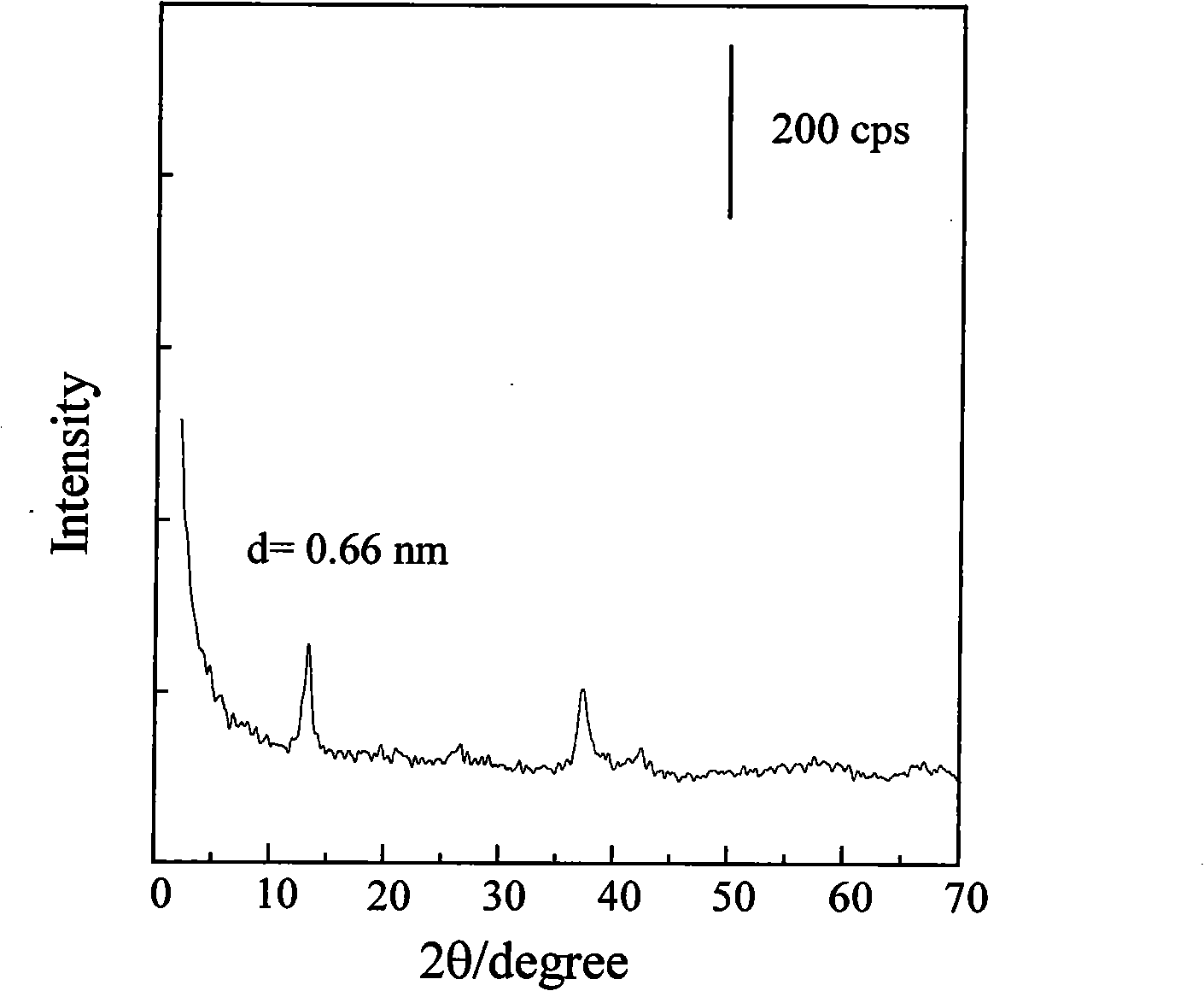

[0068] In step 4 of the assembly reaction process step 4 of the manganese dioxide nano-layer and divalent manganese ions, the stripped manganese dioxide nano-layer suspension is added to deionized water to form a concentration of 0.02mol / L Manganese nanolayer sol solution 2000mL, get 20mL concentration and be 0.1mol / L manganese nitrate aqueous solution, the Mn in manganese nitrate 2+ The molar ratio of peeling off the manganese dioxide nano-layer is 1: 20, the manganese dioxide nano-layer sol solution and the manganese nitrate solution are mixed, the resulting mixed suspension is stirred and reacted at room temperature for 24 hours, filtered, and washed with deionized water for 3 ~ 4 times, remove the divalent manganese ions adsorbed on the precipitation surface, and dry at room temperature for 12 hours to obtain layered manganese oxide intercalated with divalent manganese ions.

[0069] In step 5 of the oxidation process of the layered manganese oxide intercalated by divalent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com