Disposal solidifying and forming technique for frame and outer panel skin of wing profile

A technology of curing forming and process method, applied in aircraft assembly, aircraft parts, ground equipment and other directions, can solve the problems of heavy weight, corrosion resistance, low fatigue resistance, and high operating costs, and achieve high stiffness and strength, fatigue resistance. The effect of low capacity and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

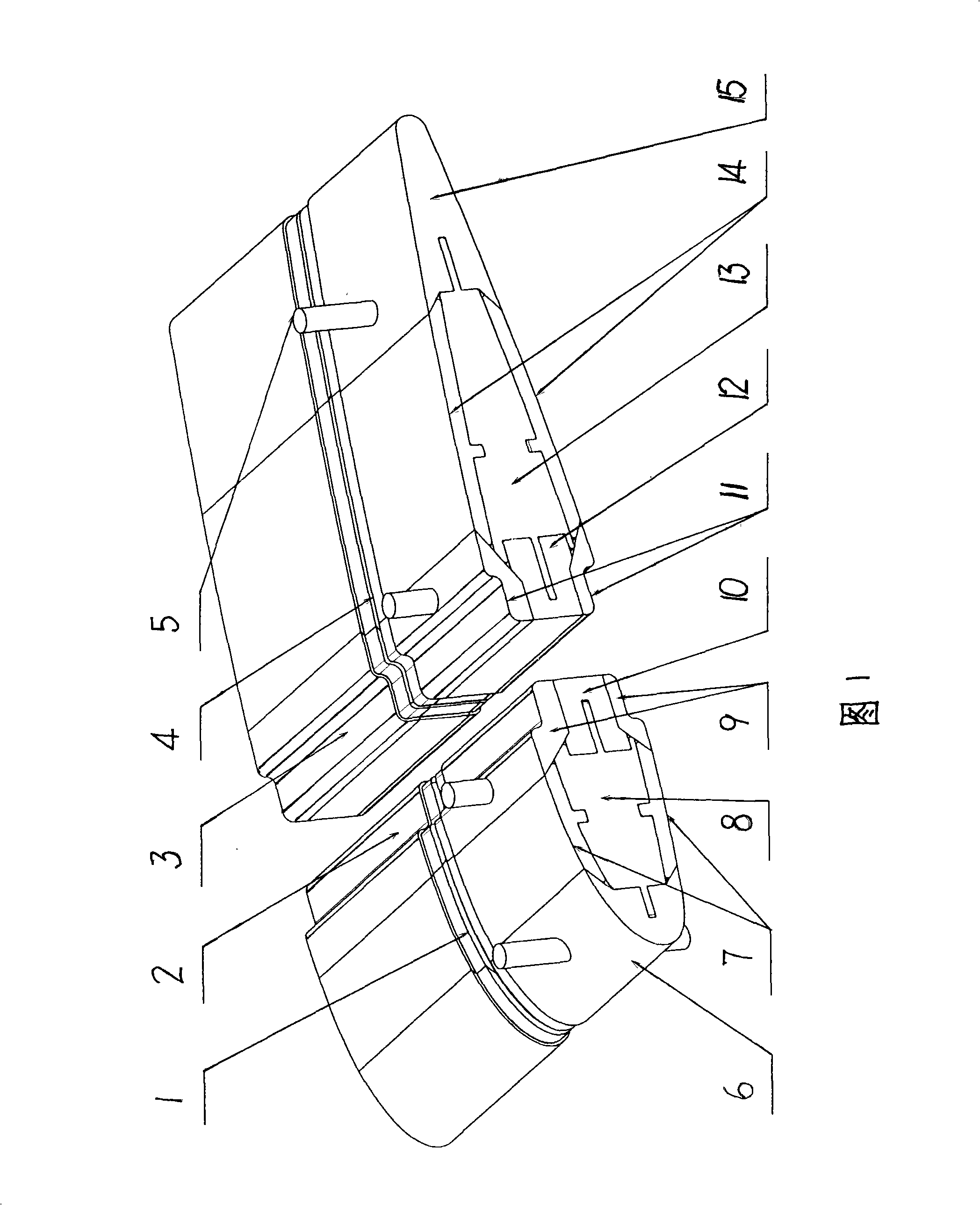

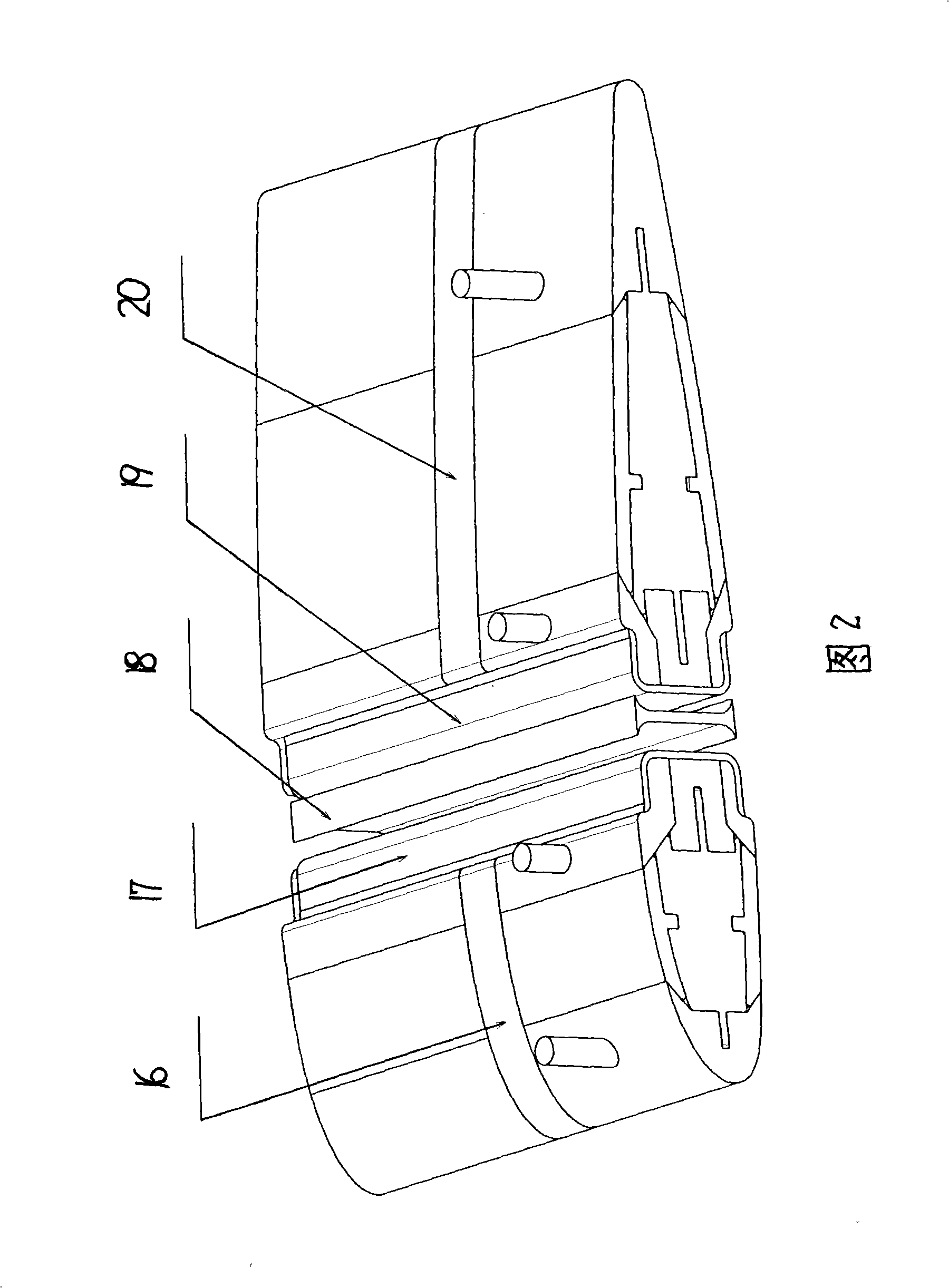

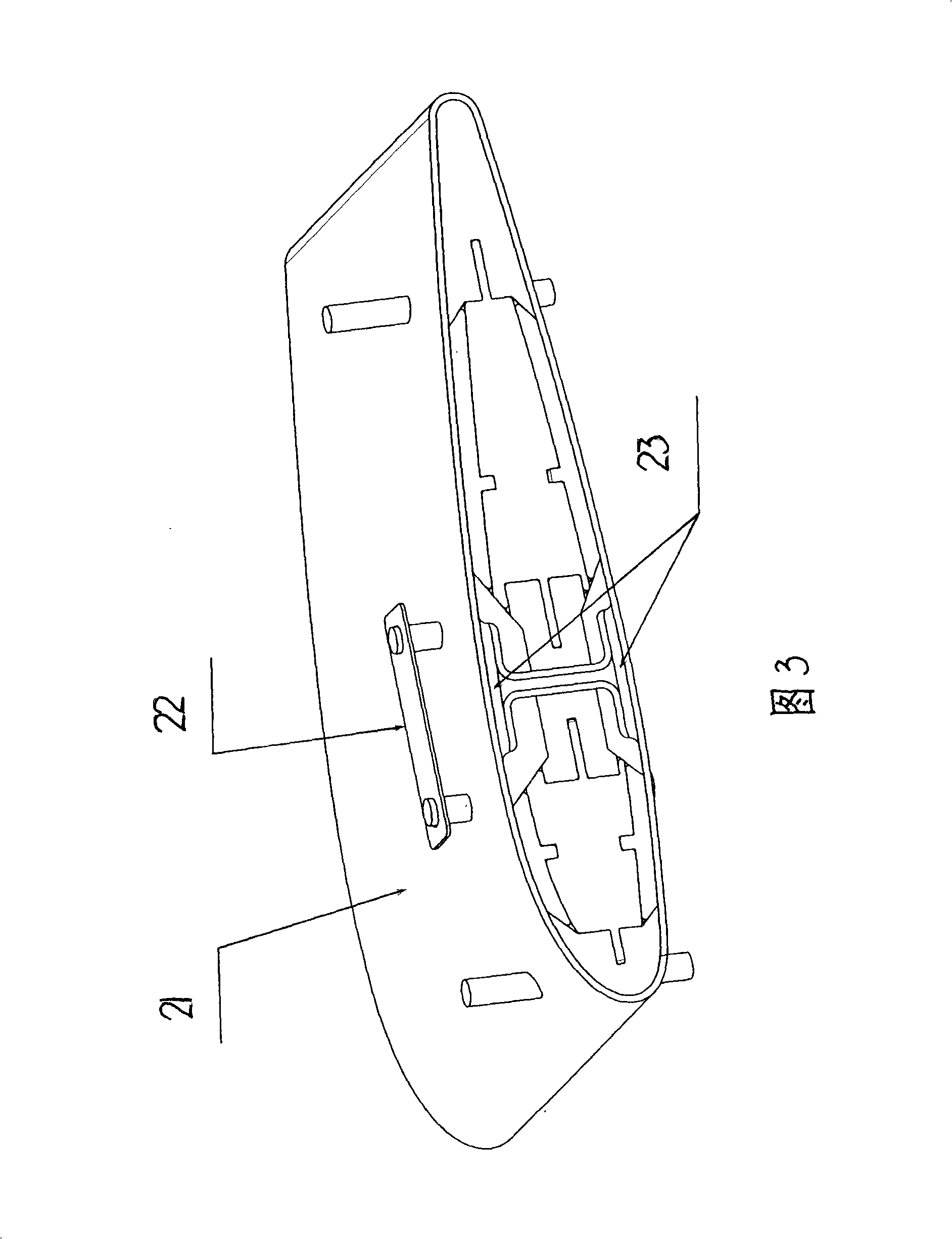

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

[0019] Figures 1 to 6 show the single-spar airfoil structure, and the multi-spar airfoil structure has the same forming principle. Combined with Figure 1, the mold of this embodiment includes a detachable built-in combination mold. A group of modules is formed from the front beam to the front edge, and a group of modules is formed from the rear beam to the rear edge. For a multi-beam structure, a group of modules is formed between the beams. The module group is composed of 6 molds and a center slide rail respectively. The front group mold includes groove 1 of transverse bulkhead, groove 2 of "I" shaped beam wing plate, front edge forming mold 6 of the front group mold, and The upper and lower forming dies 7, the center slide rail 8 of the front set of dies, the upper and lower forming dies of the longitudinal beams of the front set of dies 9, and the longitudinal beam web ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com