Printing and forming method of fluorescent powder layer of plasma display

A plasma and phosphor layer technology, which is applied in the field of printing and forming of the phosphor layer of the plasma display, can solve the problems such as the inability to realize the phosphor printing of the large-size plasma display, and achieve better control of the printing accuracy, high adhesion, The effect of improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

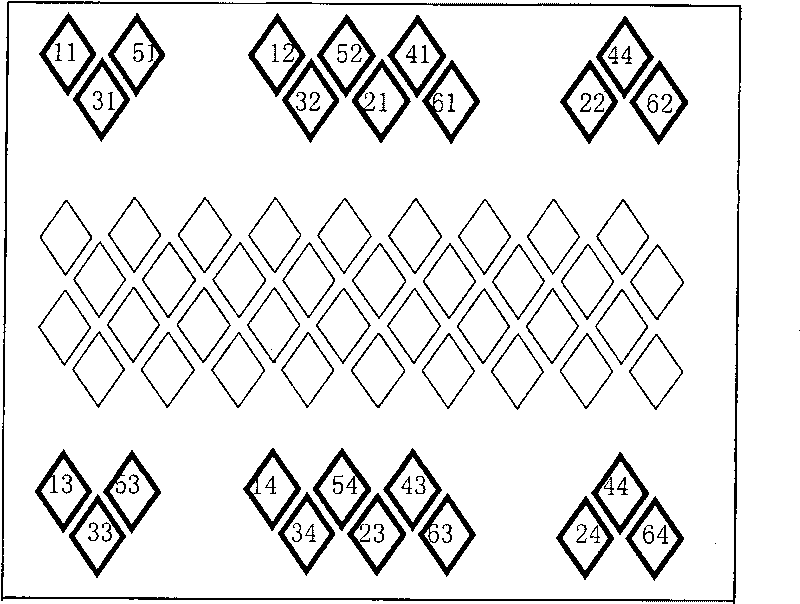

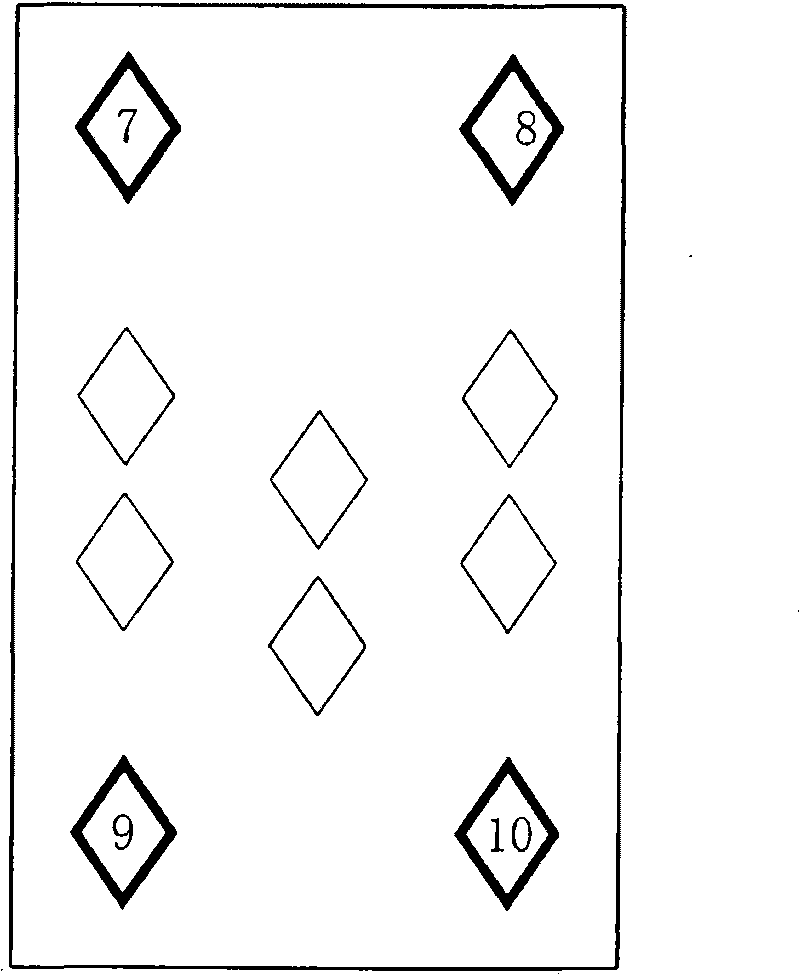

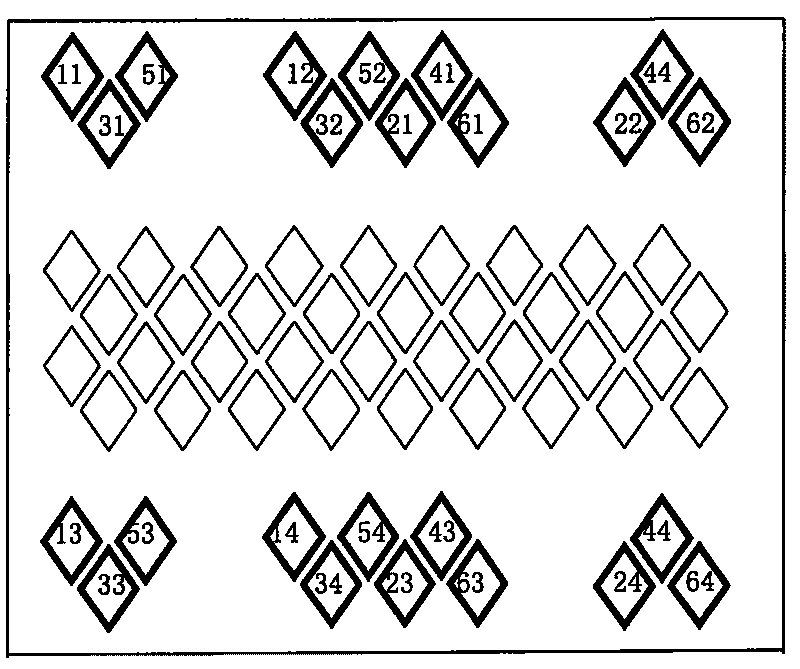

[0017] Such as figure 1 , 2 shown.

[0018] A method for printing and forming a phosphor layer of a plasma display, which uses a domestic high-precision small-size screen to print phosphor paste on the rear substrate or shadow mask of a large-scale plasma display. The steps are: first, select a Printing screen for printing large-size plasma display phosphor paste, the graphic size of the screen is half of the graphic size of the substrate, and the number of columns of through holes in the screen corresponds to the number of columns of a sub-pixel on the substrate. Secondly, set alignment marks on the top, bottom, left, and right corners of the screen, as shown in the attached figure 2 shown; and set marks at the corresponding positions on the left and right of the substrate, as attached figure 1 shown. Which attached figure 1 11, 12, 13, 14, 21, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com