Double reduction method energy-saving emission-reducing environment-friendly complete equipment

A technology for energy saving, emission reduction and complete sets of equipment, which is applied in the field of sulfur dioxide purification equipment and smoke dust, and can solve the problems of short process, large air flow resistance of purification tower, unfavorable energy saving and consumption reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

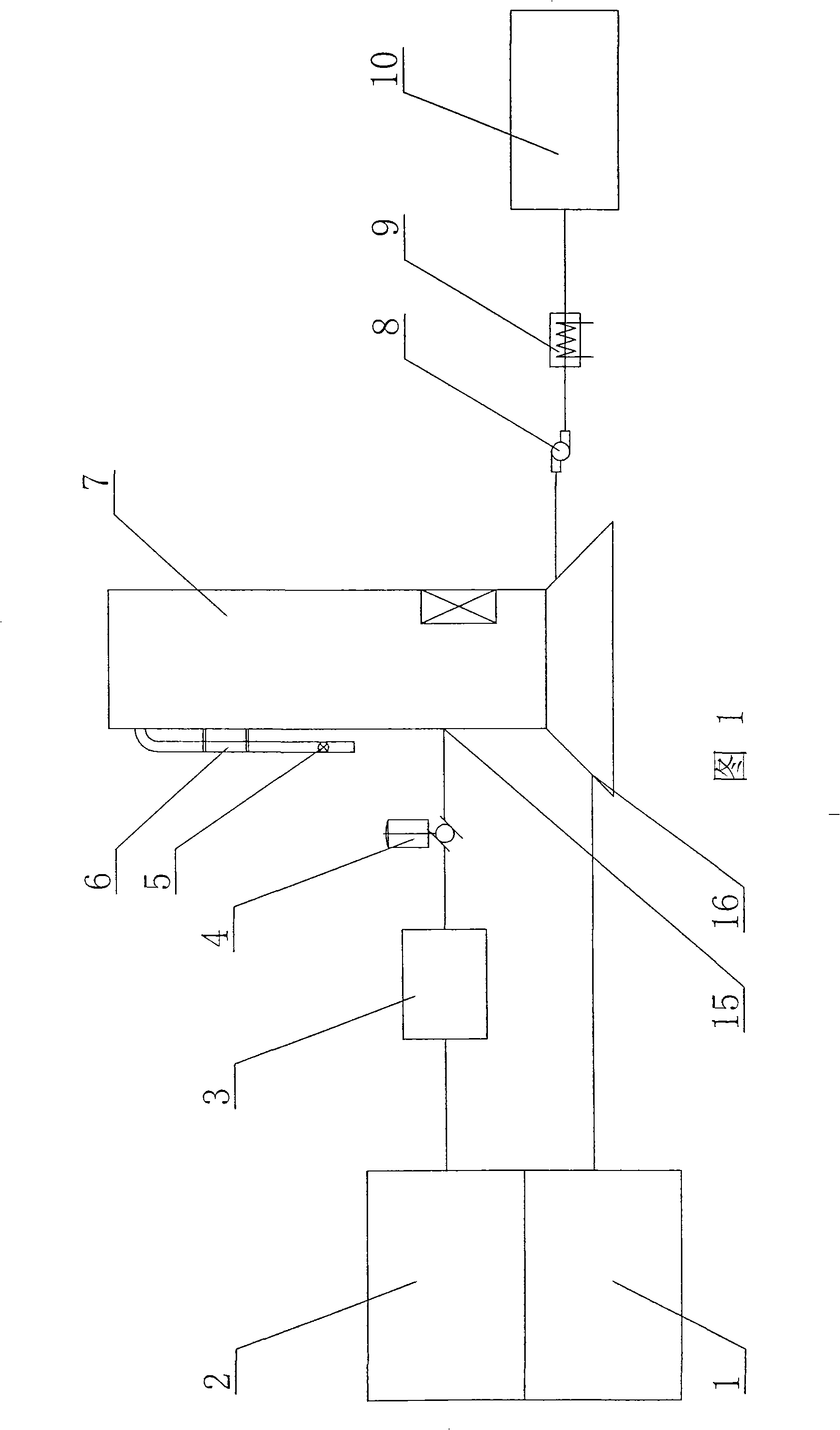

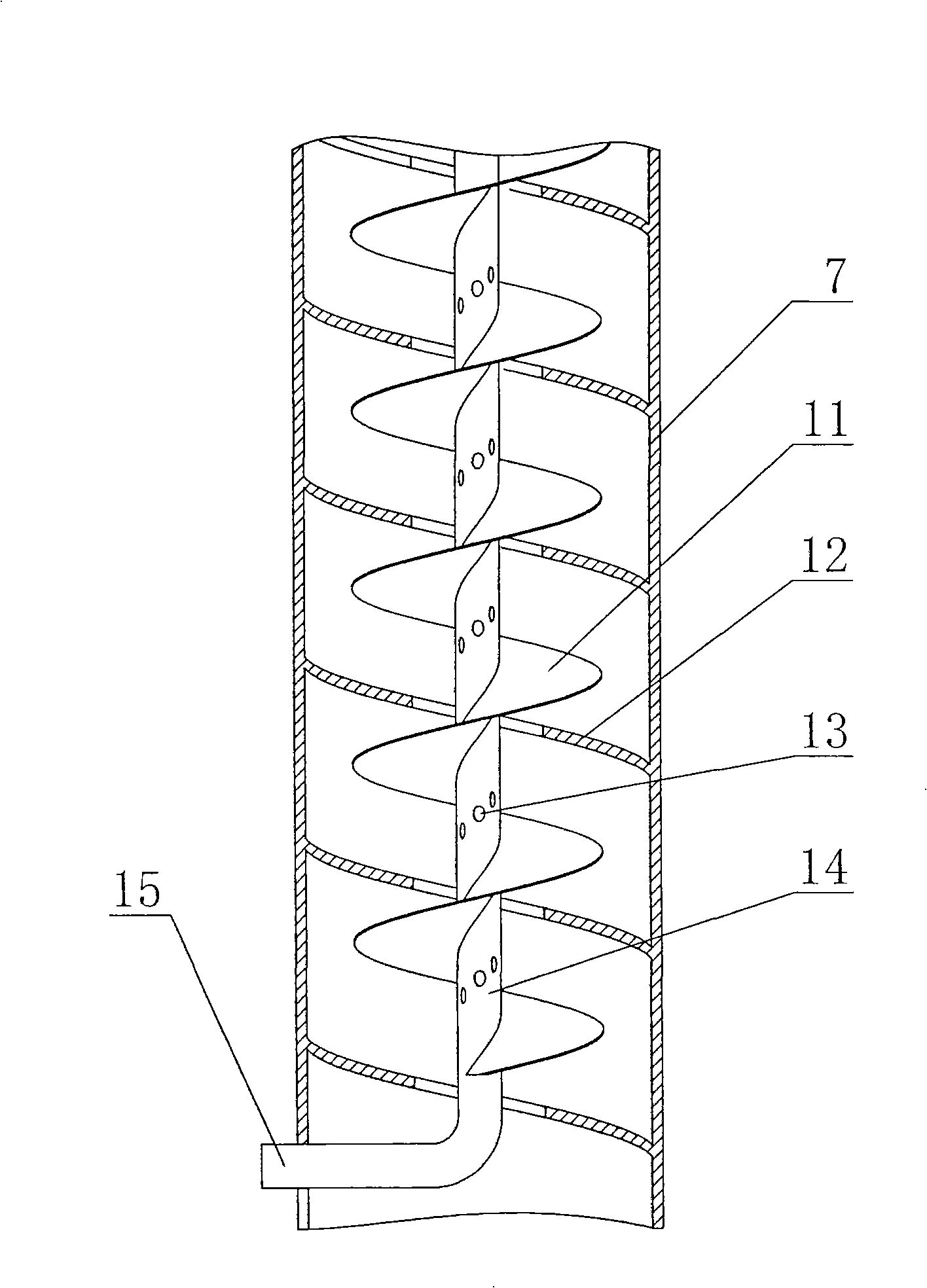

[0010] As shown in the figure, it is a complete set of double subtraction energy-saving and emission-reduction environmental protection equipment, including a high-temperature radiator 9 connected to the exhaust pipes of industrial kilns and boilers 10, and the high-temperature radiator 9 is connected to the purification tower 7 through the exhaust fan 8, and the purification tower 7 There is a water outlet 16 at the bottom, the water outlet 6 is connected to the sewage sedimentation tank 1, the sewage sedimentation tank 1 is connected to the clean water tank 2, and the clean water tank 2 passes through the chemical neutralizer 3, the anti-corrosion pump 4 and the water inlet 15 set on the purification tower Connected, the horizontal section of the purification tower 7 is circular, the water inlet 15 is connected to the vertical pipeline 14 provided in the center of the purification tower, the vertical pipeline 14 outer periphery is provided with spirally rising inner guide vane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com