Low attenuation high light efficiency LED illuminating apparatus and preparation method

A technology of LED lighting and high luminous efficiency, applied in lighting devices, lighting auxiliary devices, components of lighting devices, etc., can solve the problems of no contribution to light, waste, shortened service life, etc., to improve light output efficiency, good consistency, Good size consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with the preferred embodiment shown in accompanying drawing, be described in further detail:

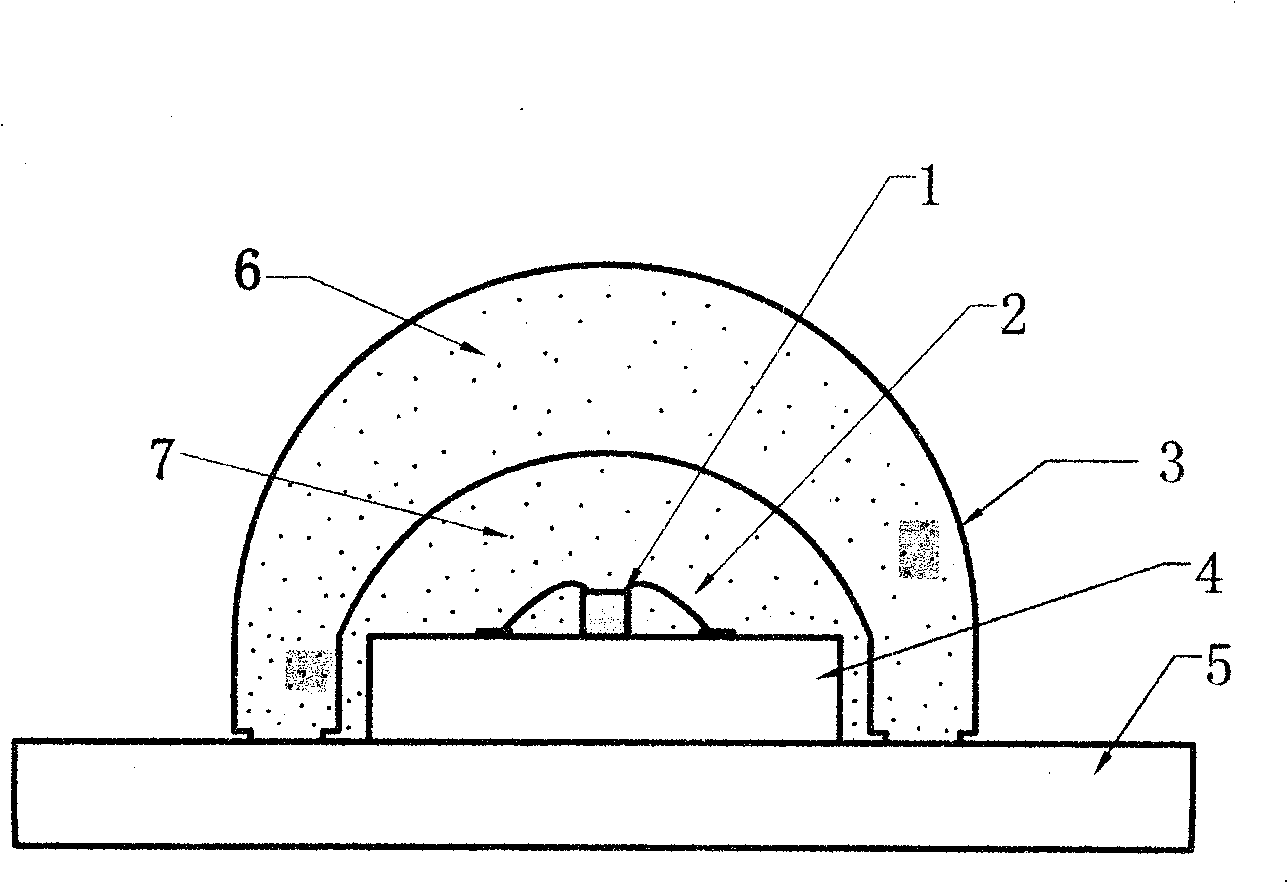

[0026] Such as figure 1 As shown, the aluminum substrate (4) is set on the heat dissipation plate (5), and the LED chip (1) is bound on the aluminum substrate (4); the positive and negative poles of the LED chip (1) are connected to the aluminum substrate (1) with a gold wire (2). The circuit connection on the substrate (4); when forming the transparent cover (3), add the fluorescent substance (6) to one-time molding; fix the transparent cover (3) containing the fluorescent substance (6) on the top of the LED chip, and place it on the aluminum chip when necessary. Silica gel or other transparent filling materials are injected between the substrate (4) and the transparent cover (3).

[0027] The structure of covering the surface of the luminescent material (4) with the liquid fluorescent substance (6) in the production process of the white light emitting d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com