Crack pouring treating method for crack of construction

A technology of building structure and treatment method, which is applied in the direction of building structure, construction, bridge construction, etc., can solve the problems of inability to check and understand the crack filling situation, the quality of filling joint treatment cannot be guaranteed, and the joint filling glue cannot be seen, etc. Achieve the effect of convenient engineering inspection and acceptance, convenient and easy implementation, and convenient measurement control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

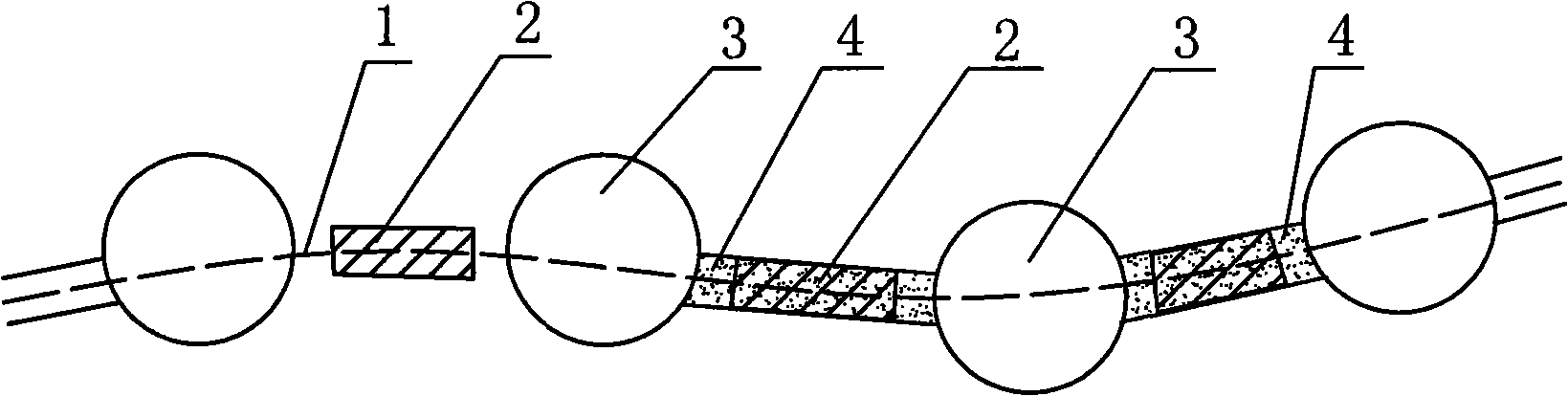

[0011] Such as figure 1 as shown,

[0012] (1) Use a grinder to grind 1.5 to 2 cm along both sides of the crack 1, and then use common tools such as wire brushes and wire wheels to remove dirt, scum, loose layers and other dirt on the crack surface until a solid surface is exposed. Then use a brush dipped in acetone, alcohol and other organic solutions, wipe it clean along the surface-treated range on both sides of the crack and keep it dry.

[0013] (2) Install the injection seat 3 along the crack, usually at a distance of 30cm, and generally leave an injection seat without an injector between 3 to 5 injection seats as an exhaust channel for the discharge of air in the crack . The injection seat should be installed firmly and completely sealed until the slurry does not leak. The center of the injection seat should coincide with the center of the crack, and the injection seat should be installed where the crack bifurcates and the crack widens.

[0014] (3) Use transparent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com