Non-contact power system polarity testing device based on magnetic flux leakage principle

A power system, non-contact technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of high misjudgment rate, low safety factor, and destructive test status, and achieve high safety factor and convenient self-inspection , the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

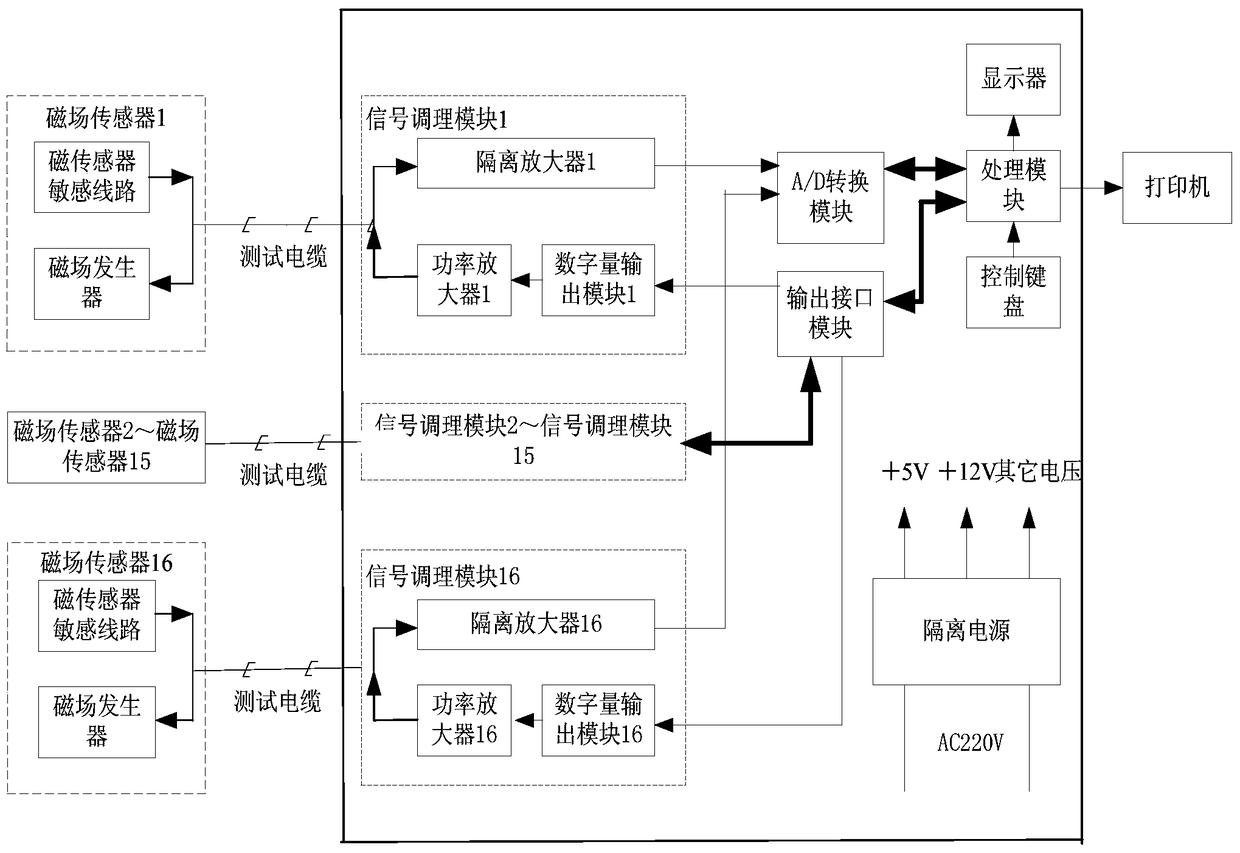

[0022] The technical solutions and beneficial effects of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] See attached figure 1 , the non-contact power system polarity testing device based on the magnetic flux leakage principle of the present invention, comprising:

[0024] At least one magnetic field sensor, the magnetic field sensor includes a magnetic sensor sensitive circuit, the magnetic sensor sensitive circuit includes a first coil winding and a transmitter, and the first coil winding is used to capture the transiently changing magnetic field near the attitude control nozzle of the power system to generate a transient The state-changing induced electromotive force signal, and the induced electromotive force signal is transformed into a voltage signal by the transmitter;

[0025] A signal conditioning module, the signal conditioning module includes an isolation amplifier, and the isola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com