Fault detection system, partial discharge on-line monitoring device and method

A partial discharge and monitoring device technology, which is applied in the field of fault detection systems and partial discharge on-line monitoring devices, and can solve problems such as mouse gnawing, sun exposure, and faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

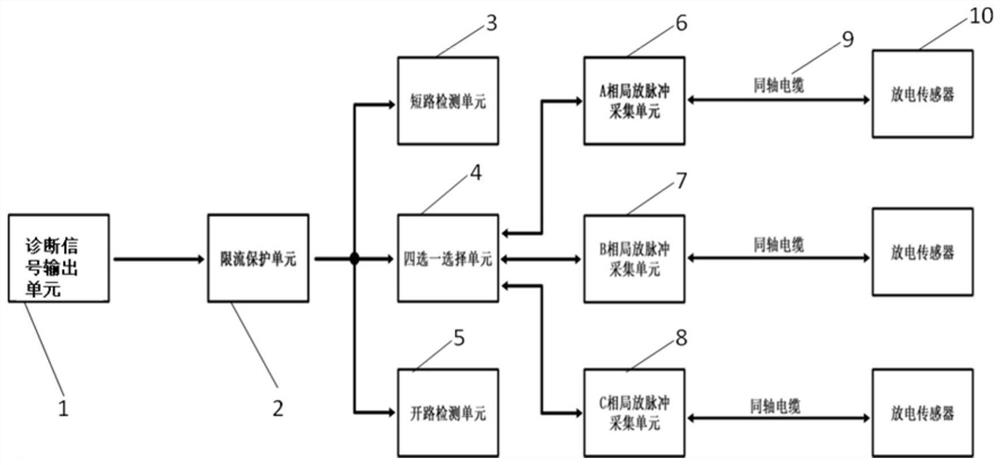

Embodiment 1

[0049] Such as figure 1 As shown, a partial discharge on-line monitoring device integrated with a fault detection system is shown, including a diagnostic signal output unit 1, a current limiting protection unit 2, a short circuit detection unit 3, a selection unit 4, an open circuit detection unit 5, a phase A Discharge pulse acquisition unit 6, phase B partial discharge pulse acquisition unit 7, phase C partial discharge pulse acquisition unit 8, coaxial cable 9, discharge sensor 10, diagnostic signal output unit 1 is a signal source for self-diagnosis, which can output Pulse signal, DC level signal; diagnostic signal output unit 1 connects current limiting protection unit 2 after outputting self-diagnostic signal source to realize signal protection; current limiting protection unit 2 is connected to four-choice one signal selection unit 4, the selection unit 4 Three of them are merged into A-phase partial discharge pulse acquisition unit 6, B-phase partial discharge pulse ac...

Embodiment 2

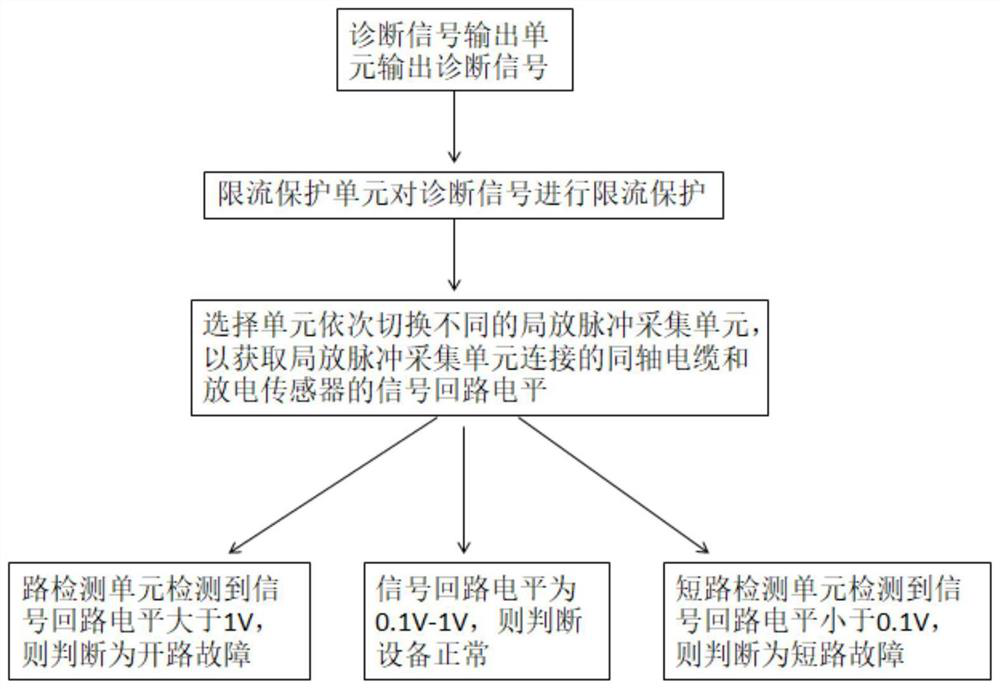

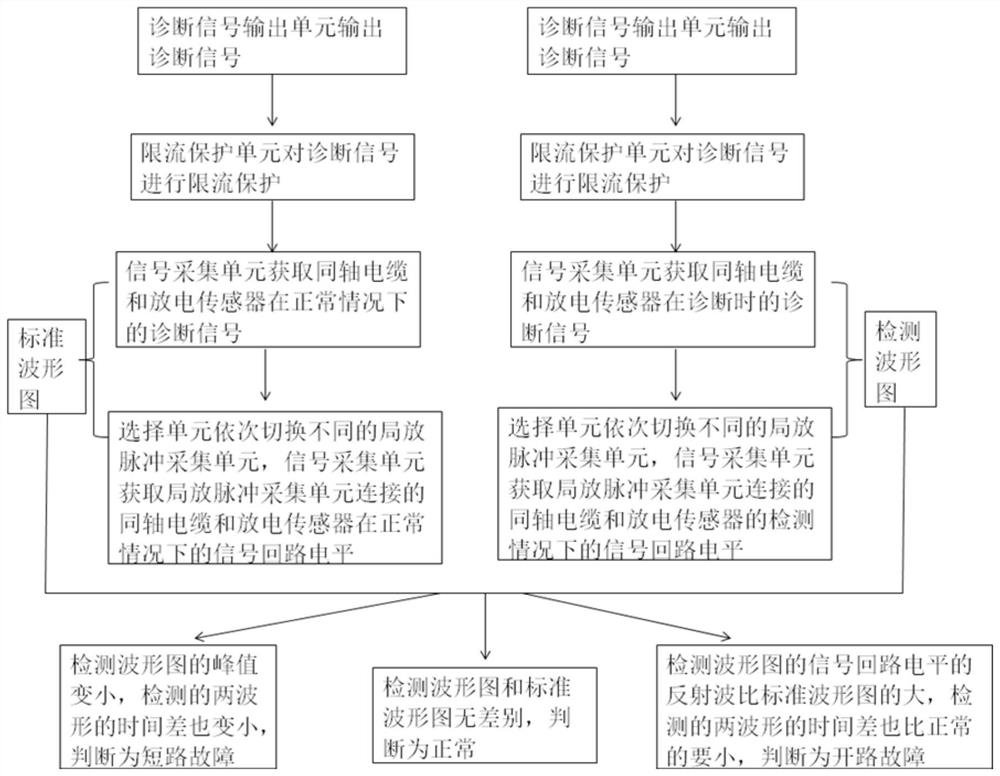

[0065] The diagnostic signal output unit outputs a DC level, such as 5V level, the output current is limited to 10mA through the current limiting protection unit, and the four-selection unit polls and switches A\B\C three-phase acquisition input channel unit, under normal circumstances Because the coaxial cable, discharge sensor and protector make the signal loop level within 1V, the open circuit detection unit can judge according to the level, and it is considered open circuit if it is greater than 1V.

Embodiment 3

[0067] The diagnostic signal output unit outputs a DC level, such as 5V level, the output current is limited to 10mA through the current limiting protection unit, and the four-selection unit polls and switches A\B\C three-phase acquisition input channel unit, under normal circumstances Because the coaxial cable, discharge sensor and protector make the signal loop level above 0.1V, the short circuit detection unit can judge according to the level, and if it is less than 0.1V, it is considered a short circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com