Excitant for preparing construction material by carbonized curing wastes

A technology of building materials and carbonization maintenance, applied in the field of building materials, can solve problems such as low carbonization rate, increase carbonization rate, and shorten production cycle, and achieve the effect of increasing carbonization rate, promoting carbonization, and shortening production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

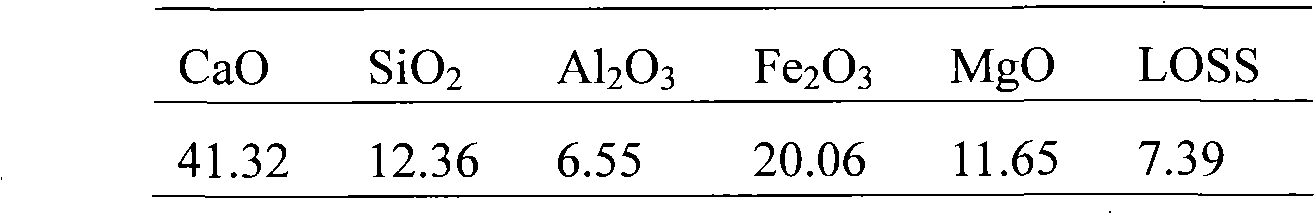

[0018] The steel slag discharged by Jinan Iron and Steel Group is selected as the carbonized material, and its chemical composition is:

[0019]

[0020] Mix the above carbonized materials and water evenly, press them into standard blocks, and use industrial CO 2 gas for conservation, CO 2 The concentration is 20% by weight, and the carbonization curing temperature is 100°C. After two hours of curing, finished bricks are made. After carbonization curing, the weight increase of steel slag bricks absorbs CO 2 About 12%, its strength is about 15MPa.

[0021] Also mix the above-mentioned steel slag carbonization raw materials with activator and water, and adopt the same preparation process, the weight of steel slag bricks increases to absorb CO 2 About 15%, its strength is about 18MPa.

[0022] The addition of the activator accounts for wt5% of the steel slag carbide material, and the activator contains wt80% NaHCO 3 .

Embodiment 2

[0024] Select the steel slag discharged by Jinan Iron and Steel Group as raw material (same as embodiment 1).

[0025] Mix the above raw materials and water evenly, press them into standard blocks, and use industrial CO 2 gas for conservation, CO 2 The concentration is 20% by weight, and the carbonization curing temperature is 80°C. After two hours of curing, finished bricks are made. After carbonization curing, the weight of carbonized bricks increases to absorb CO 2 8%, and its strength is about 10MPa.

[0026] Also mix the above-mentioned steel slag carbonization raw materials with activator and water evenly, and adopt the same preparation process, the weight increase of steel slag bricks will absorb CO 2 13.5%, and its strength is about 17MPa.

[0027] The addition of described activator accounts for the wt10% of steel slag carbonization raw material, contains the gypsum of wt50% and the Ca(HCO of wt40% in the activator 3 ) 2 .

Embodiment 3

[0029] Select waste cement as carbonized material, its chemical composition and its weight percentage are:

[0030]

[0031] Mix the above raw materials with air-entraining agent and water evenly, press them into air-entrained concrete blocks, and use CO 2 The industrial waste gas with a weight of 45% is used for curing, the curing gas pressure is 5 bar, and the carbonization curing temperature is 150°C. After 3 hours of curing, carbonized aerated concrete blocks are made.

[0032] After carbonation curing, the weight increase of aerated concrete block absorbs CO 2 15%, and its strength is about 4MPa.

[0033] Also mix the above-mentioned waste cement carbonization raw materials with activator, air-entraining agent and water evenly, and adopt the same preparation process, the weight increase of carbonized air-entraining concrete block will absorb CO 2 19%, and its strength is about 6.5MPa.

[0034] The activator is water glass (Na 2 SiO 3 ), its solid content is wt 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com