Regeneration artificial board

A technology of wood-based panels and splints, which is applied in the direction of manufacturing tools, the joining of wooden veneers, and wood processing equipment, etc., can solve the problems of consuming forest resources and polluting the environment, and achieve the goals of saving forest resources, protecting the environment, and reducing processing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

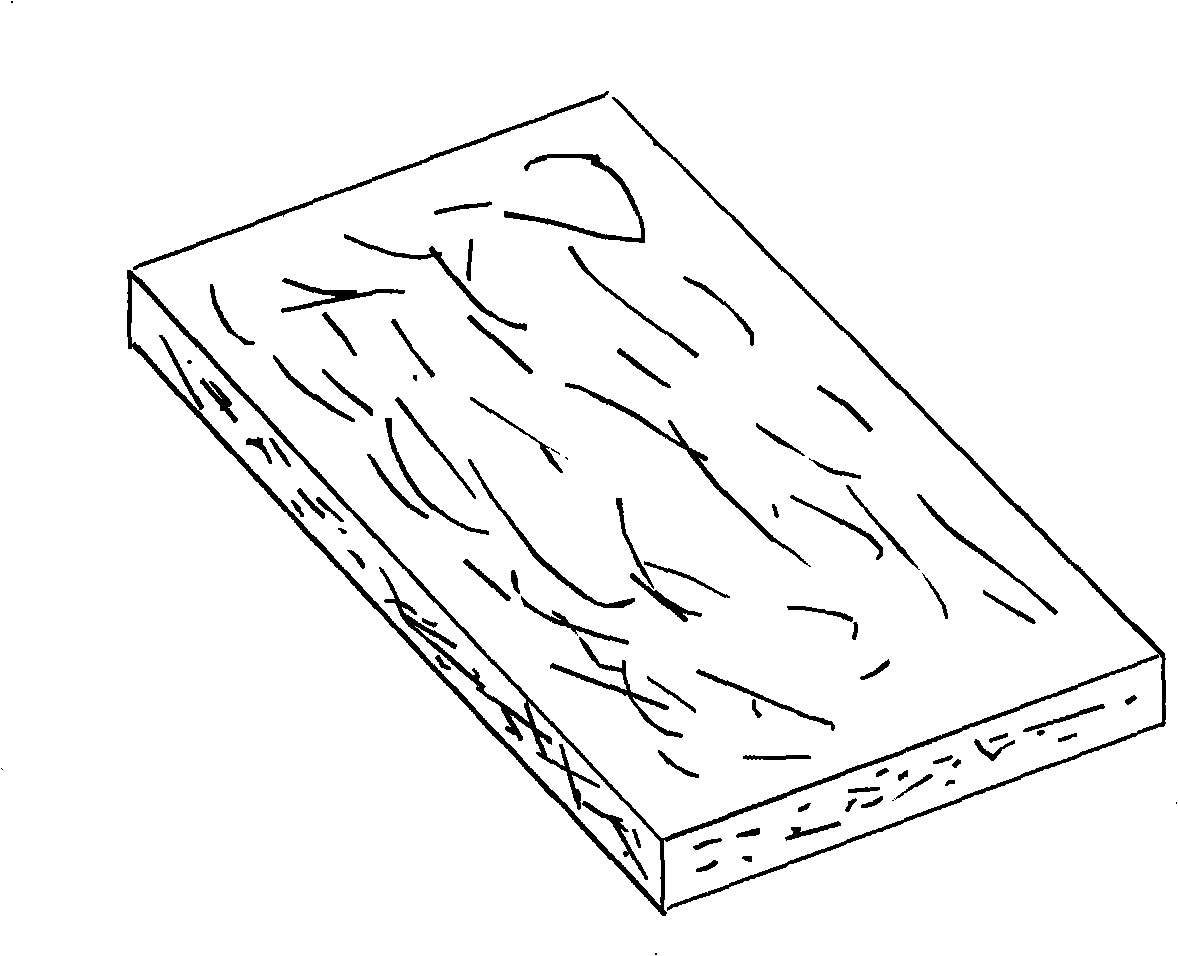

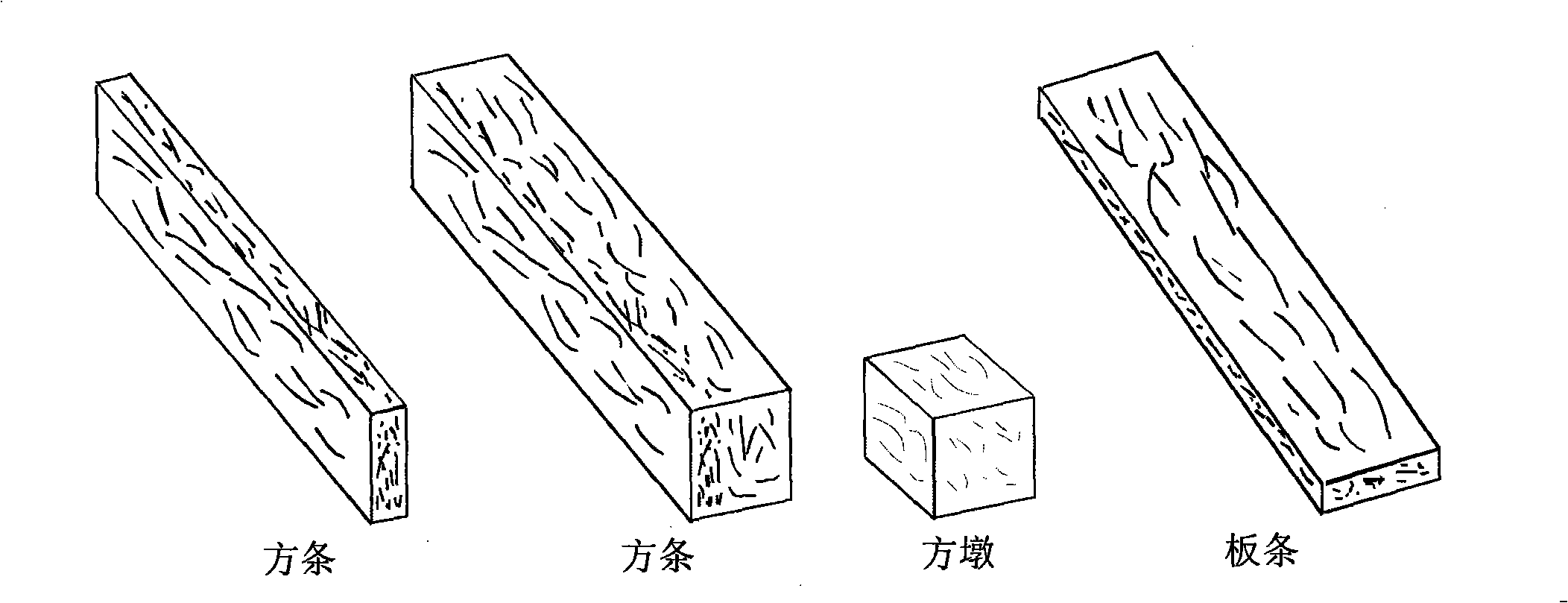

[0021] see figure 1 , Raw materials for recycled wood-based panels (composite particle boards): wood shavings, sawdust, wood chips, bamboo silk, etc., are mixed evenly with resin glue in proportion, placed flat on a fixed hydraulic mold, and then subjected to high temperature and heavy pressure, (Note: The greater the glue ratio, the heavier the pressure, and the harder the hardness of the composite particleboard.) For example, a small board can be directly pressed into a mold for demoulding without sawing, and a large board should be cut into four sides and then cut into specifications. The finished product can also be sawed into various square bars, square piers, strips, etc. according to the application. (Such as figure 2 )

[0022] The recycled wood-based panels (composite particle boards) can usually be made into the regular dimensions of length × width × thickness as shown in the table below.

[0023] Table 1: (The marked size is mm)

[0024] Overall size:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com