Cold rolling continuous annealing units steel coil optimizing ordering method and its system

A technology for optimizing sorting and sorting methods, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

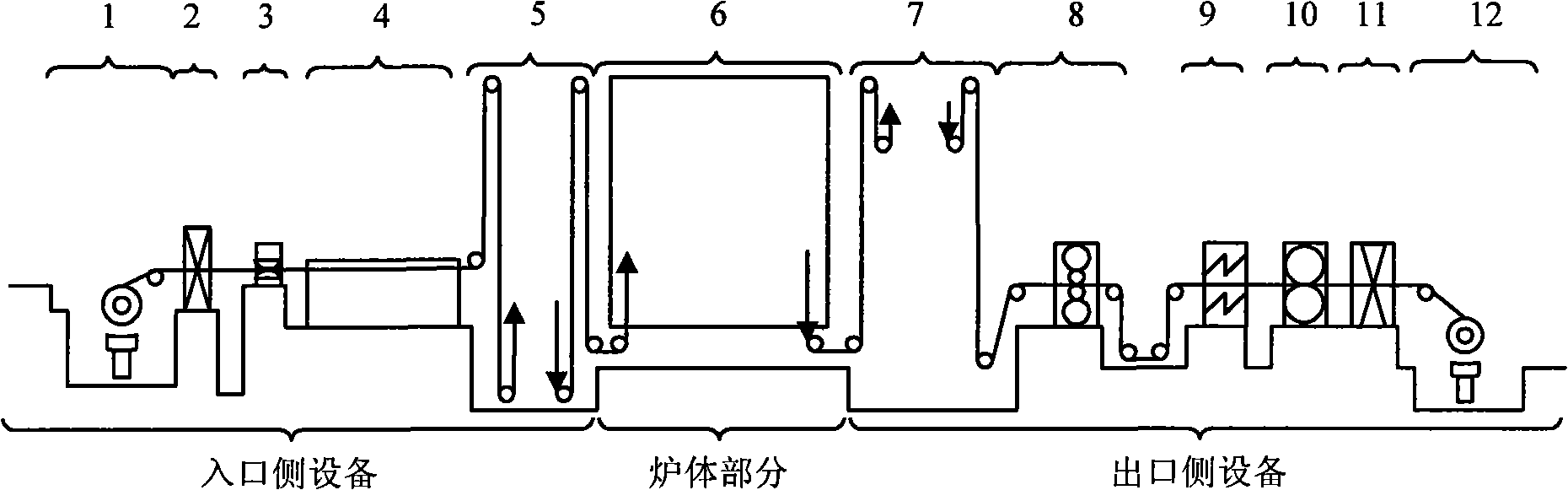

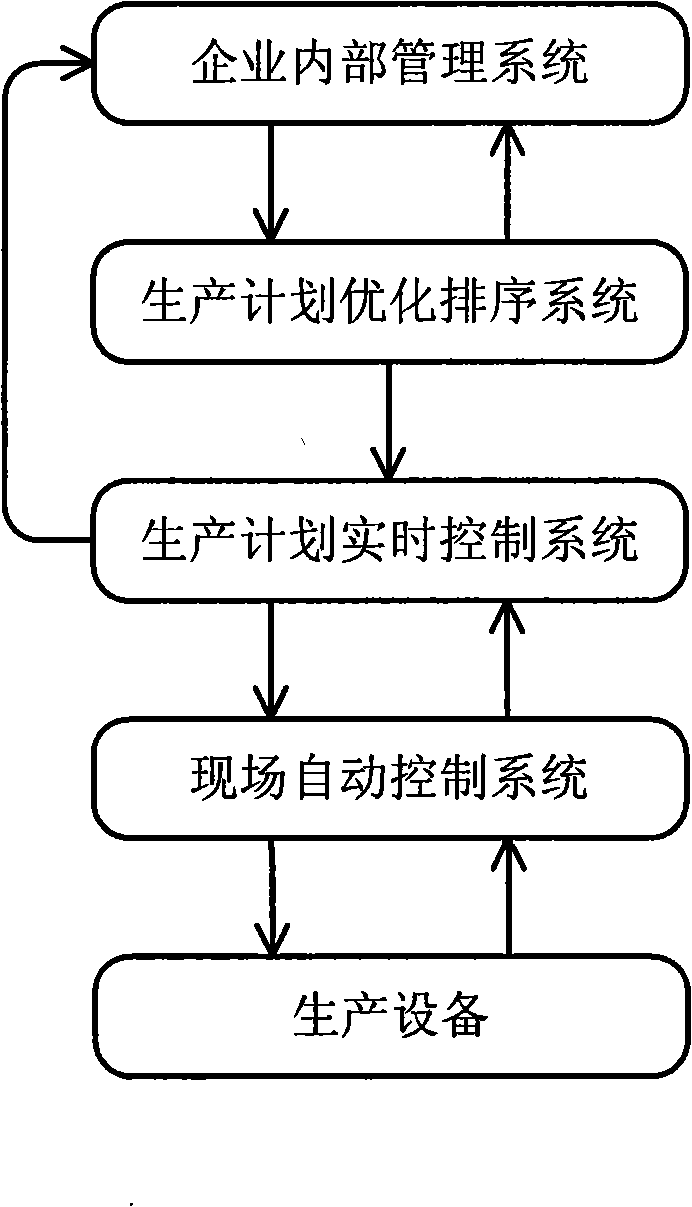

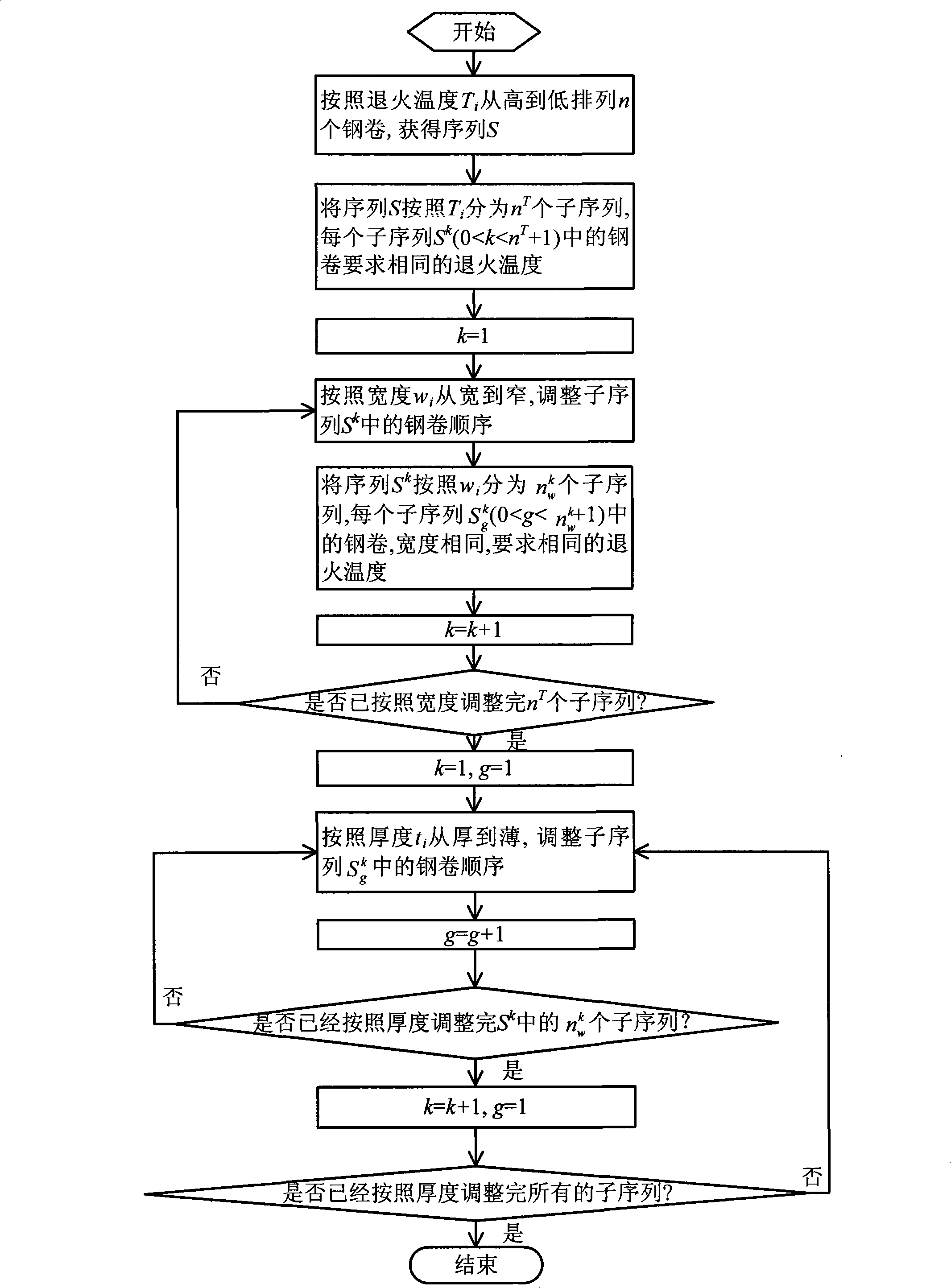

[0104] The following takes the continuous annealing production process of iron and steel enterprises as the background and describes in detail in conjunction with the accompanying drawings.

[0105] The implementation of the system of the present invention requires the following devices: at least one PC; at least one cable interface or optical cable interface or telephone dedicated line interface; at least one router. These devices provide the hardware basis for the optimal sequencing of steel coils in continuous annealing units. The software support required by the system includes: Windows operating system as a support platform, installation of Microsoft SQL Server 2000 database system to support data management, and configuration of information transmission ports. The PC is used to realize and operate the optimization system of the present invention, and communication equipment such as routers and cable interfaces are used to realize the communication connection between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com