Air-cooler utilizing residual heat

An air cooler and waste heat technology, applied in the field of coolers and air coolers, can solve problems such as a single cooling function, and achieve the effect of solving process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

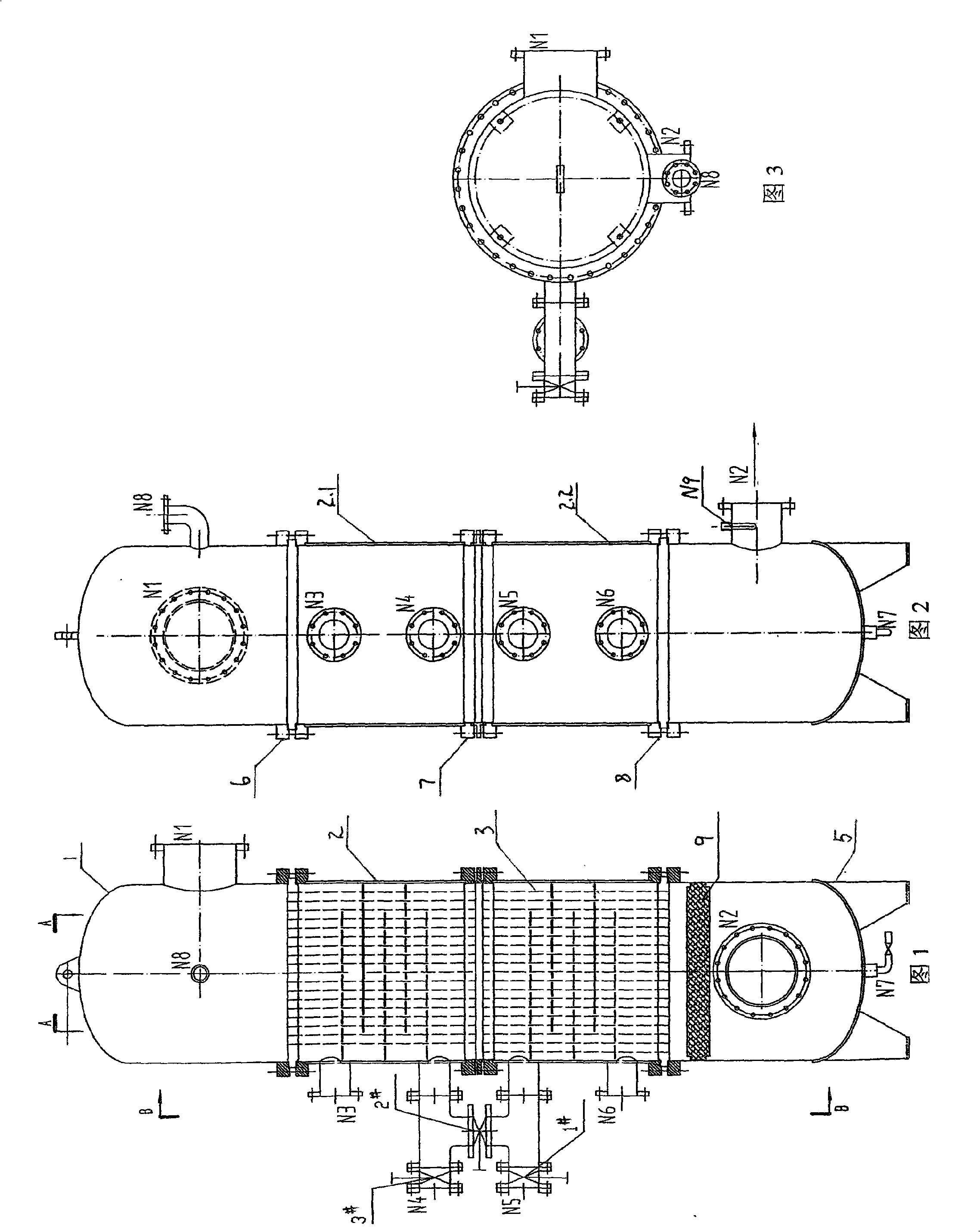

[0013] Referring to FIGS. 1-3 , the novel air cooler utilizing waste heat involved in the present invention is mainly composed of an upper tube box 1 , a cylinder body 2 , a heat exchange tube bundle 3 and a lower tube box 5 . The upper tube box 1 and the lower tube box 5 are arranged at the upper and lower ends of the cylinder body 2. The cylinder body 2 is divided into two sections, the upper cylinder body 2.1 and the lower cylinder body 2.2. The upper cylinder body 2.1 is a high temperature zone, and the lower cylinder body 2.2 is a low-temperature zone, and two heat exchange tube bundles 3 are axially arranged in the upper cylinder and the lower cylinder respectively. The upper cylinder 2.1 and the upper tube box 1 are connected by flange I 6, the upper cylinder 2.1 and the lower tube 2.2 are connected by flange II 7, and the lower cylinder 2.2 and the lower tube box 5 are connected by flange III8 connected.

[0014] The wall of the upper cylinder 2.1 is provided with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com