Pneumatic device for machining deep ring slots on inner cylindrical surface

An inner cylindrical, pneumatic technology, applied in the direction of drive devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems that deep ring grooves cannot be machined, mechanical processing cannot be realized, and radial cutting cannot be realized, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

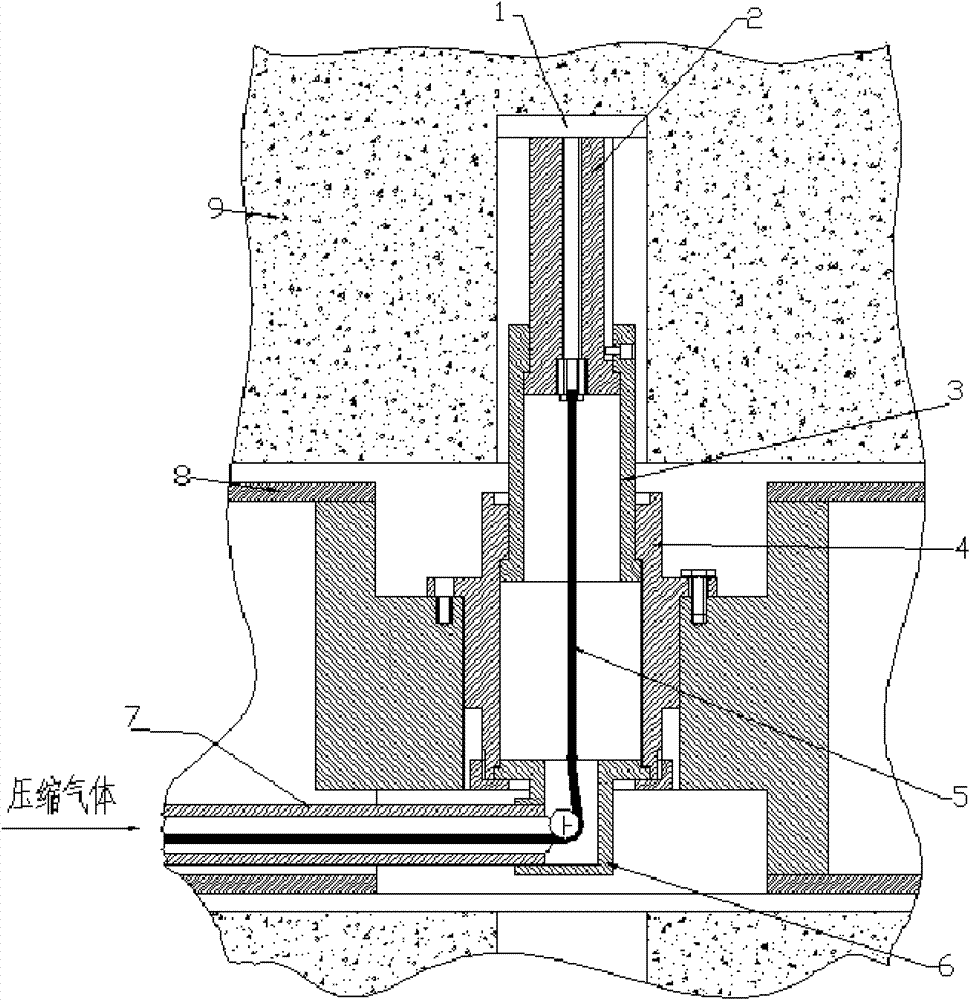

[0013] Shown with reference to accompanying drawing, device of the present invention is mainly made of parts such as cutter 1, telescopic knife rest 2,3, knife rest seat 4, steel rope 5 and elbow 6, gas conduit 7.

[0014] Tool 1 is a forming knife with the same width as the ring groove.

[0015] Cutter 1 is contained on the telescopic knife rest 2, and telescopic knife rest 2 and 3 are contained in the knife rest seat 4, and elbow 6 and gas conduit 7 are affixed with knife rest seat 4. One end of steel wire rope 5 is affixed to cutter, and the other end passes through gas conduit 7 and joins with servo motor (not shown in the figure).

[0016] The telescopic knife rest 2 can slide in the telescopic knife rest 3 , and the telescopic knife rest 3 can move axially along the knife rest seat 4 . The tensioning and loosening of the wire rope 5 are controlled by a servo motor. A certain amount of compressed air is required for work.

[0017] This device is placed in the steel pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com