Method for producing medium-high-carbon high-strength steel based on sheet bar technology

A technology of high-strength steel and a production method, which is applied in the field of thin slab continuous casting and rolling technology, can solve the problems of low metal yield, low metal yield, long production cycle, etc., achieves huge economic benefits, improves metal Yield, product cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

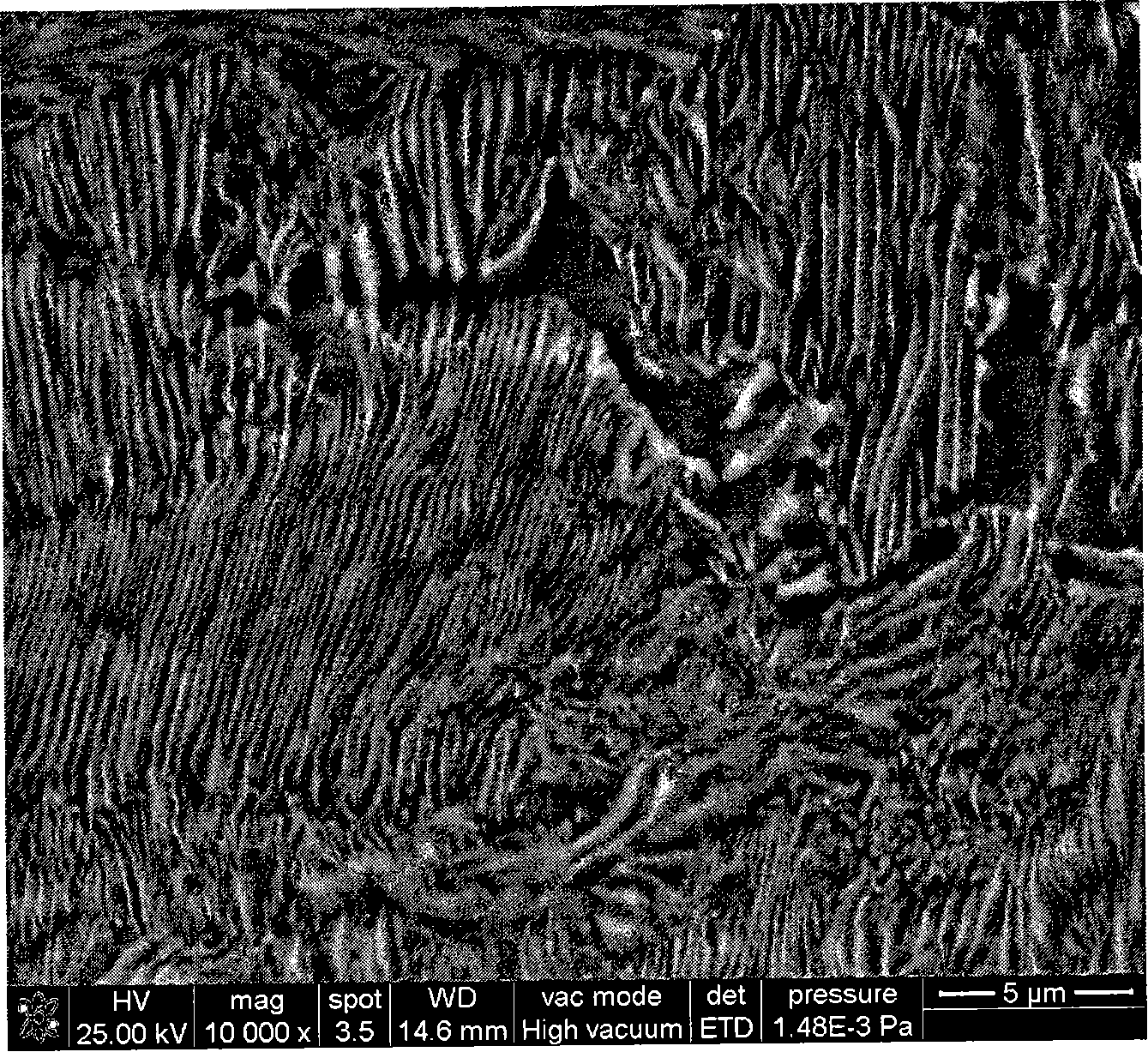

Embodiment 1

[0032] A production method of medium-high carbon high-strength steel based on thin slab technology. According to the chemical composition of the steel and the characteristics of the thin plate continuous casting and rolling process, the molten iron is smelted into molten steel by a converter, and the molten steel is refined after converter steelmaking, and the deoxidizer Al and alloying elements Si and Mn are added for deoxidation and alloying , Al is controlled at 0.010% to 0.040wt%. [Ca] / [Al] ratio is controlled between 0.05 and 0.18. After molten steel is refined, thin slab continuous casting is carried out. The thickness of the thin slab is 70mm, and the continuous casting uses high carbon steel mold slag. After solidification, the slab directly enters the roller hearth heating furnace and soaking furnace, and then undergoes hot continuous rolling, cooling and coiling. Among them: the thickness of the continuous casting slab is 70mm, the casting speed of the continuous c...

Embodiment 2

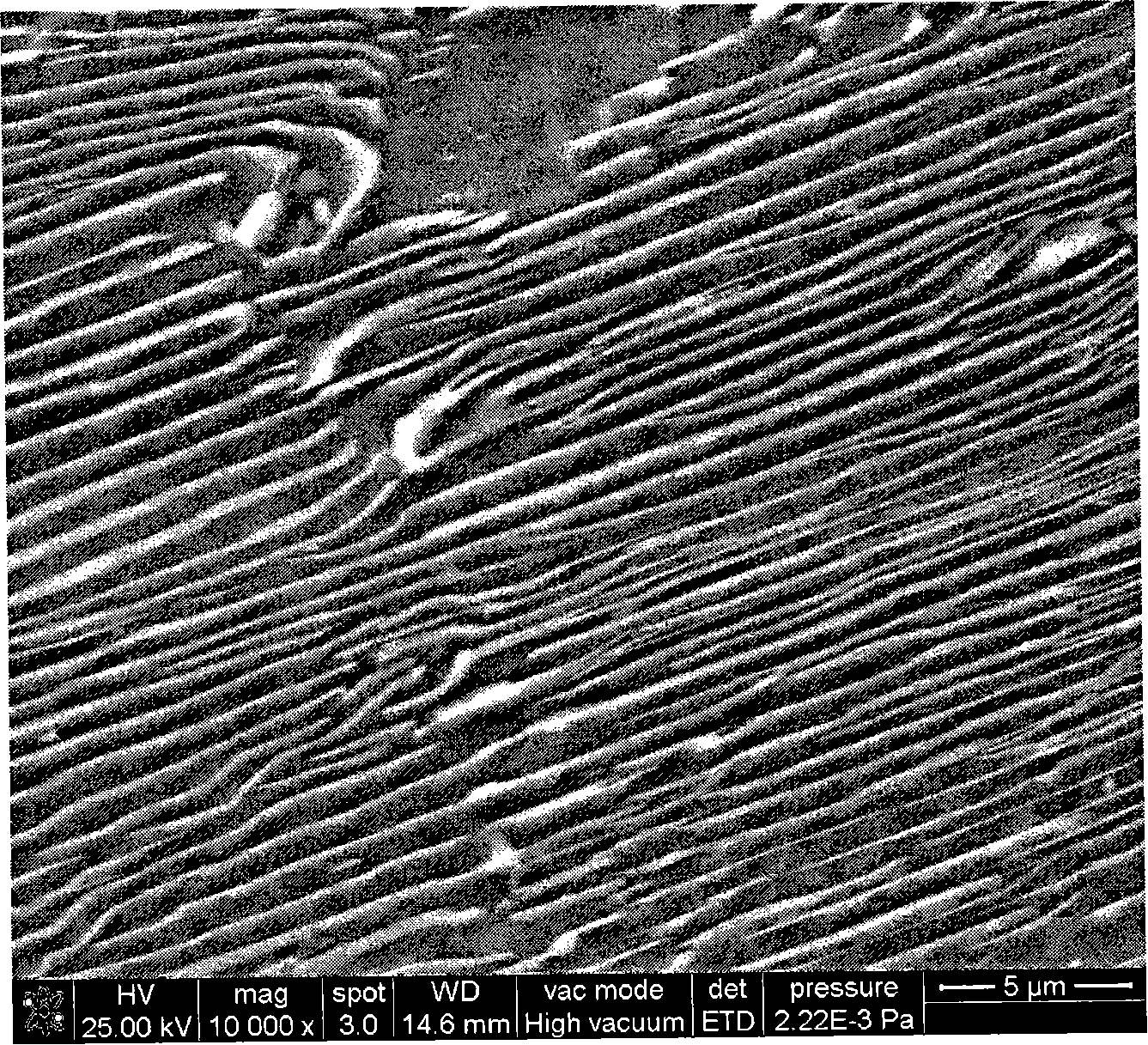

[0037] A production method of medium-high carbon high-strength steel based on thin slab technology. According to the chemical composition of the steel and the characteristics of the thin plate continuous casting and rolling process, the molten steel is refined after converter steelmaking, and the deoxidizer Al and alloying elements Si, Mn, Cr, Mo are added for deoxidation and alloying. Al is controlled at 0.010% to 0.040%. [Ca] / [Al] ratio is controlled between 0.05 and 0.18. Thin slab continuous casting is carried out after molten steel is refined, and the thickness of the thin slab is 90 mm, and medium carbon steel mold slag is used for continuous casting. After solidification, the slab directly enters the roller hearth heating furnace and soaking furnace, and then undergoes hot continuous rolling, cooling and coiling. Among them: the thickness of the continuous casting slab is 90mm, the casting speed of the thin slab continuous casting is 3.5-4.5m / min, the temperature of t...

Embodiment 3

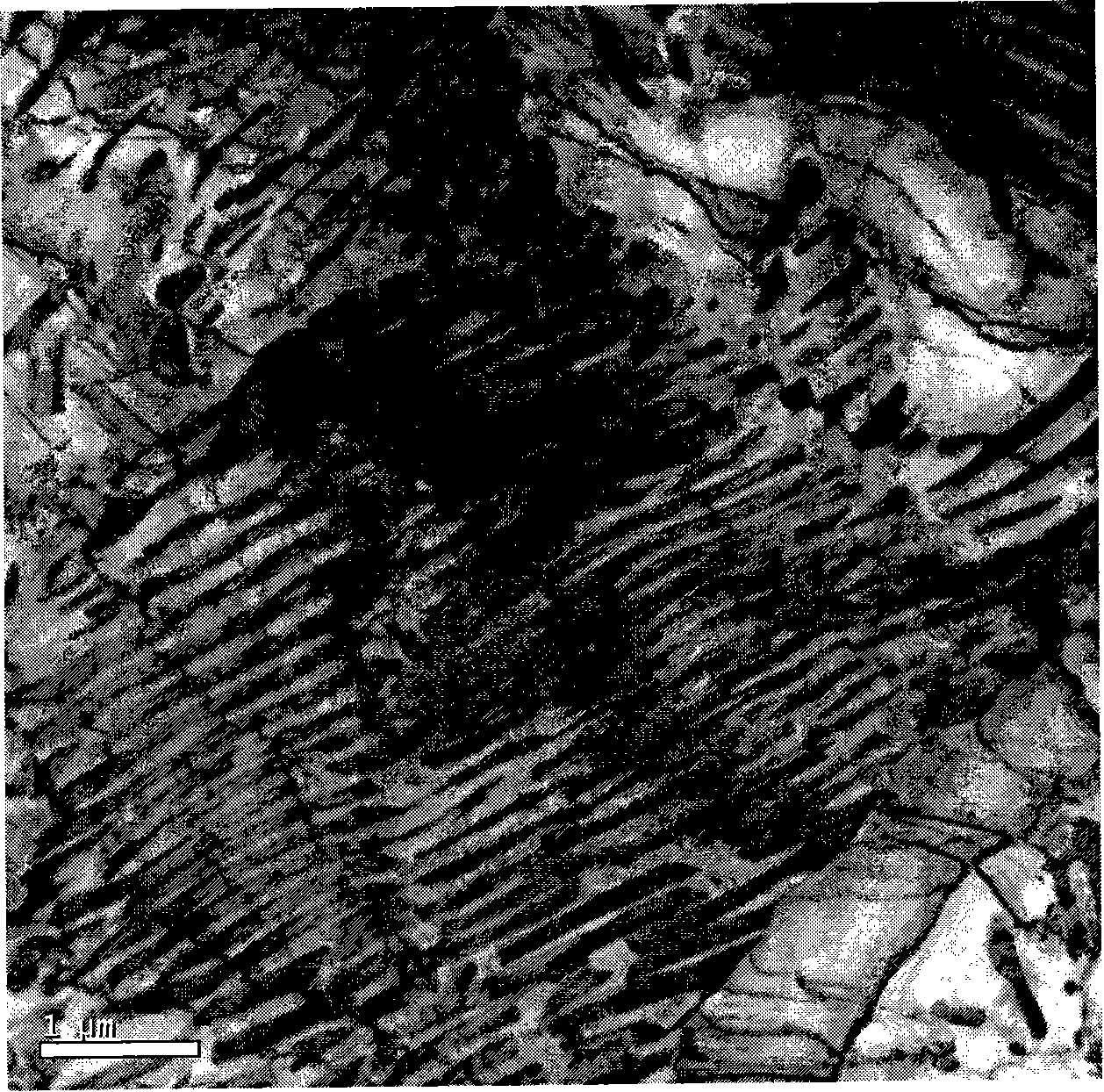

[0042] A production method of medium-high carbon high-strength steel based on thin slab technology. According to the chemical composition of the steel and the characteristics of the thin plate continuous casting and rolling process, the molten steel is refined after converter steelmaking, and the deoxidizer Al and alloying elements Si, Mn, Cu, W are added for deoxidation and alloying. The Al is controlled at 0.010% to 0.040wt%. [Ca] / [Al] ratio is controlled between 0.05 and 0.18. After molten steel is refined, thin slab continuous casting is carried out. The thickness of the thin slab is 50mm. The continuous casting uses medium-carbon steel mold slag. Pick. Among them: the thickness of the thin slab is 50mm, the casting speed of the thin slab continuous casting is 4.5-6.0m / min, the temperature of the slab entering the heating furnace is 900-1020°C, and the temperature of the slab entering the soaking furnace is 1050-1150°C, The starting temperature of hot continuous rolling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com