Adhesive for LED chip

A technology of LED chips and bonding glue, which is applied in the direction of adhesives, inorganic adhesives, electrical components, etc., can solve the problems of adding LED chips, low thermal conductivity, unfavorable heat dissipation of devices and high temperature working stability, etc., to achieve increased bonding The effect of strength, high brightness, and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

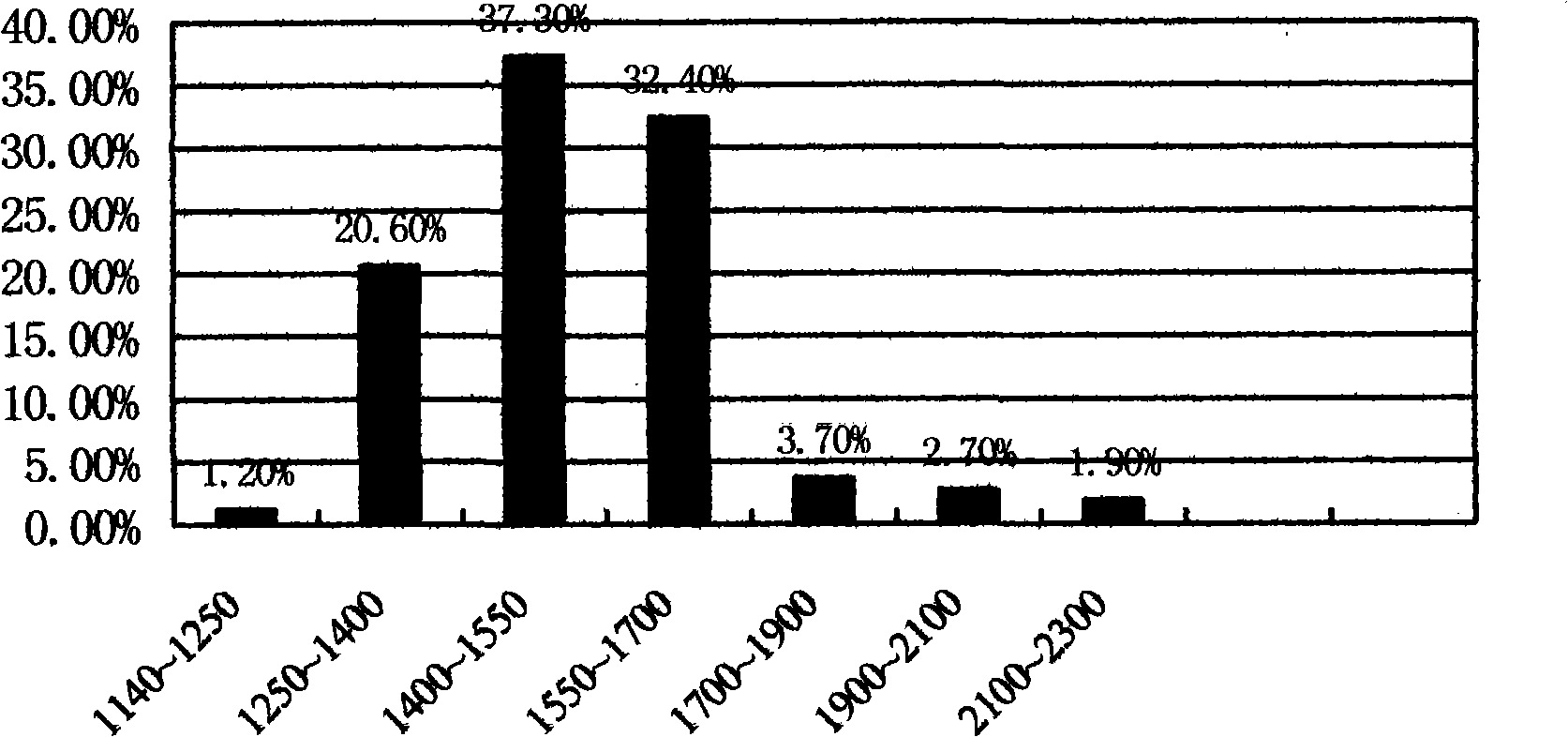

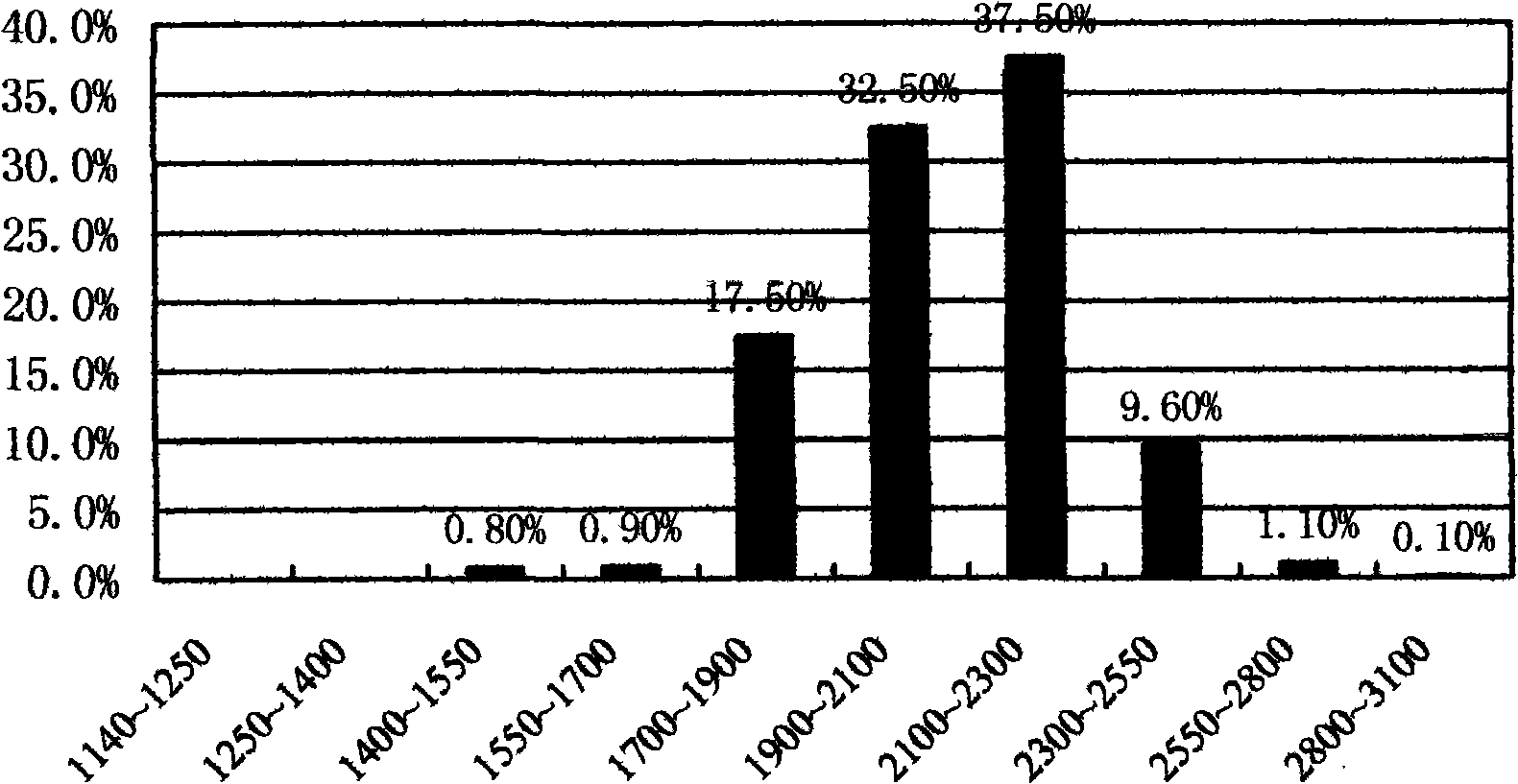

[0015] Using different characteristics of chip bonding glue, using the same LED chip, the same packaging process and packaging glue to make white PLCC LED, the test distribution results of the luminous intensity are as follows Figure 1~3 As shown (the test instrument is WEIMING LED-638T, test conditions: Ta: 25°C, RH 45% IF = 20mA)

[0016] The test results show that, using the same LED chip, the same packaging process, and using adhesives with different characteristics, under the premise that the electrical properties and CIE blocks of white PLCC LEDs are basically the same, the brightness will be very different. This is due to the different characteristics The different adhesives are caused by the difference in light transmittance, refractive index, etc. It can be seen from the comparison that the material of the present invention will be of great help to improve the brightness of the LED.

Embodiment 2

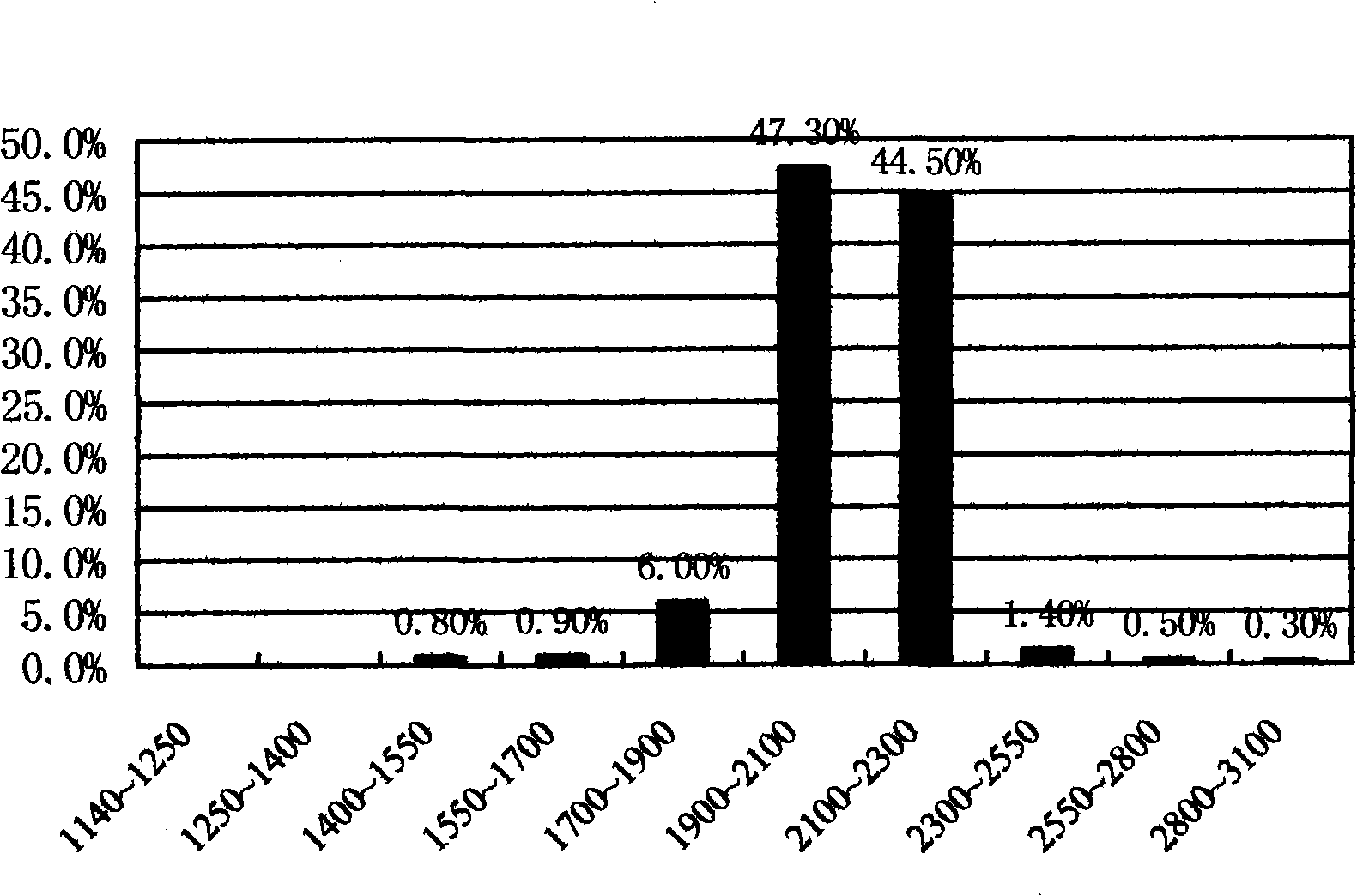

[0018] Compare the brightness decay curves of epoxy resin and silicone bonding materials, such as Figure 4 , Figure 5 As shown, test conditions: Ta: 25°C, RH 45, IF=20mA, 1000HRS. Through the verification of the overall reliability experiment, the reliability of the bonding material of the present invention is better than that of the EPOXY structure.

Embodiment 3

[0020] A kind of LED chip bonding glue, the composition of this chip bonding glue is: the transparent optical silica gel (Dow Corning OE-6660 Part A / B TransparentSilicone Resin (Dow Corning Corporation OE-6660A / B component, transparent silicone resin)), also contains AL which accounts for 10-20% of the weight of silica gel 2 o 3 With silica gel weight 2 ~ 10% SiO 2 Powder and sedimentation inhibitor. Precipitation inhibitor is cyclohexanone or ethyl acetate; AL 2 o 3 and SiO 2 Particle size 50m 2 / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com