Low refractive index fluoropolymer coating compositions for use in antireflective polymer films

A low-refractive index, anti-reflection coating technology, used in coatings, thin material processing, instruments, etc., can solve the problem of reducing the surface energy of the coating, reducing the interface adhesion, increasing the fluorine content of the fluoropolymer coating, etc. question

Inactive Publication Date: 2007-12-26

3M INNOVATIVE PROPERTIES CO

View PDF26 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, increasing the fluorine content of the fluoropolymer coating reduces the surface energy of the coating, which in turn reduces the bond between the fluoropolymer layer and other polymer layers or the substrate layer (to which the fluoropolymer layer is attached). interfacial adhesion

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0124] The following paragraphs illustrate the improvement of each composition step used to form the low refractive index composition of the present invention through a set of specific reaction examples and experimental methods. These paragraphs detail the test methods, ingredients, and experimental tests done to prove the improvement of each composition step.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

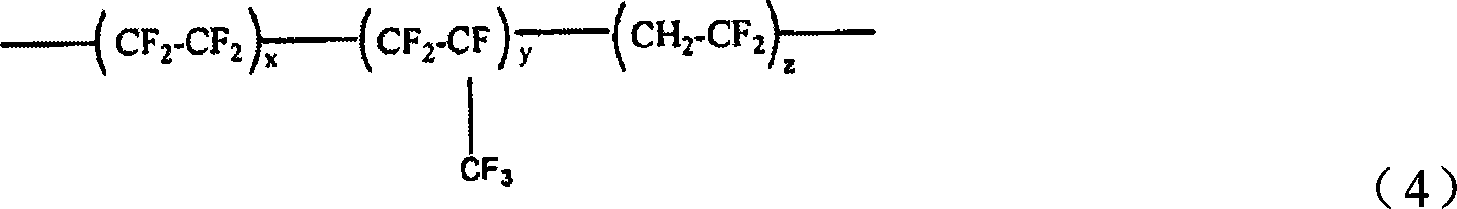

An economic, optically transmissive, stain and ink repellent, durable low refractive index fluoropolymer composition for use in an antireflection film or coupled to an optical display. In one aspect of the invention, the composition is formed from the reaction product of a fluoropolymer or reactive fluoropolymer, an amino silane ester coupling agent or ester equivalent, a multi-olefinic crosslinker, and optional surface modified inorganic particles or sol gel precursors.

Description

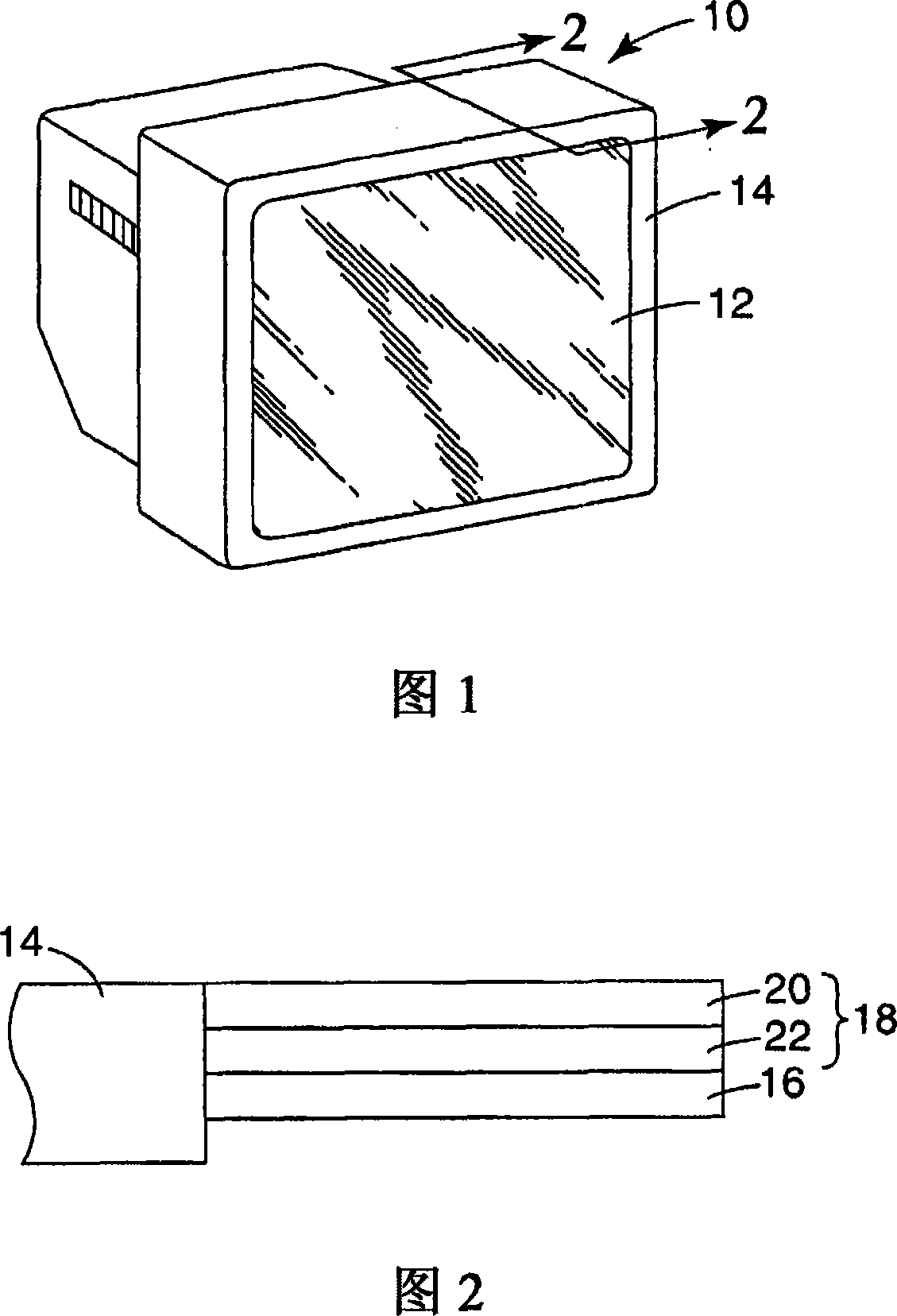

[0001] Technical field and industrial applicability [0002] The present invention relates to an anti-reflection film, and more specifically, the present invention relates to a low refractive index fluoropolymer coating composition for an anti-reflection polymer film. Background technique [0003] In the display industry, anti-reflective polymer films ("AR films") are becoming increasingly important. People are developing new applications for low-refractive-index films that are coated on the substrates of products used in computers, televisions, appliances, mobile phones, aerospace, and automotive industries. [0004] In order to reduce the amount of light reflected by the surface of the optical display, AR films are usually constructed by alternating high refractive index ("RI") and low refractive index polymer layers. In AR films used on optical articles, the desired product is characterized by a low percentage of reflected light (for example, 1.5% or less) and resistance to scra...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G02B1/10G02B1/11

CPCY10T428/31663G02B1/111Y10T428/3154Y10T428/24942G02B1/10G02B1/11B82Y40/00

Inventor 景乃勇曹春涛福士达夫蒂莫西·J·塔特格威廉·D·科焦克里斯托弗·B·小沃克托马斯·P·克伦威廉·J·舒尔茨裘再明

Owner 3M INNOVATIVE PROPERTIES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com