Rigid and flexible composite bio-fillers for deodorization by bio trickling filtration and method for preparing same

A bio-filler and bio-trickling filtration technology, which is applied in the direction of sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of unfavorable microbial reproduction and survival, low treatment efficiency of bio-trickling filters, and the interception rate of odorous gases Low-level problems, to achieve multiple attachment growth points, improve the defects of the hanging film, and avoid the effects of microbial malnutrition

Inactive Publication Date: 2010-12-01

ZHEJIANG UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although it has good molding processability, it is easy to make fillers with complex shapes and large specific surface areas, but because these materials have smooth surfaces and no internal void structures, it is not conducive to the reproduction and survival of microorganisms, especially when dealing with odorous gases. Sometimes there are problems of difficulty in film formation and long period of film formation; at the same time, because these inorganic materials themselves cannot provide nutrients for microorganisms, the supply of external nutrients becomes one of the limiting factors for the growth and reproduction of microorganisms; in addition, because polymer fillers generally have specific The shape and hardness are relatively high. After filling into the biotrickling filter, it often causes the problems of low bulk density and large void ratio. The filler has a low interception rate for malodorous gases, which in turn leads to low treatment efficiency of the biotrickling filter.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

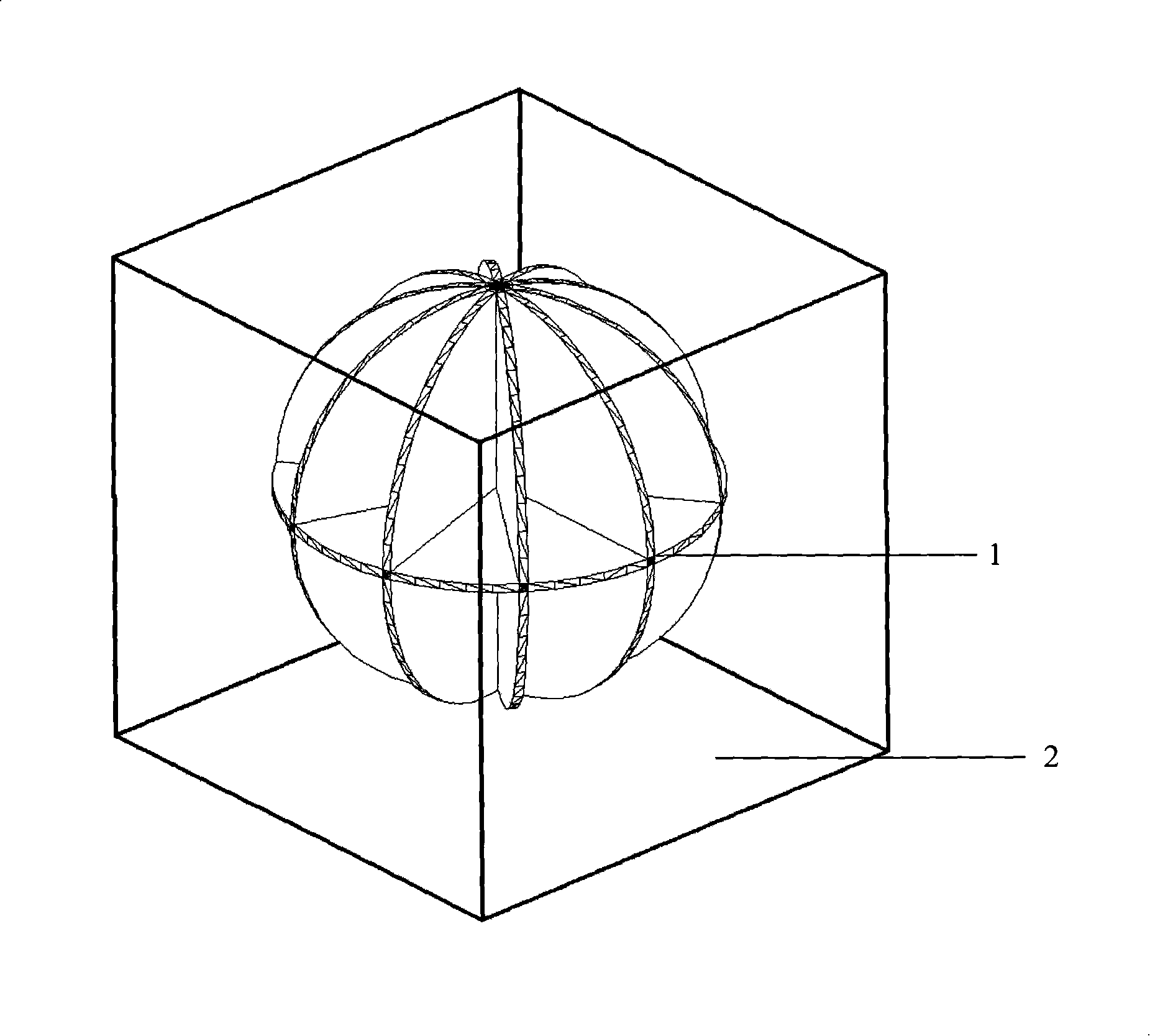

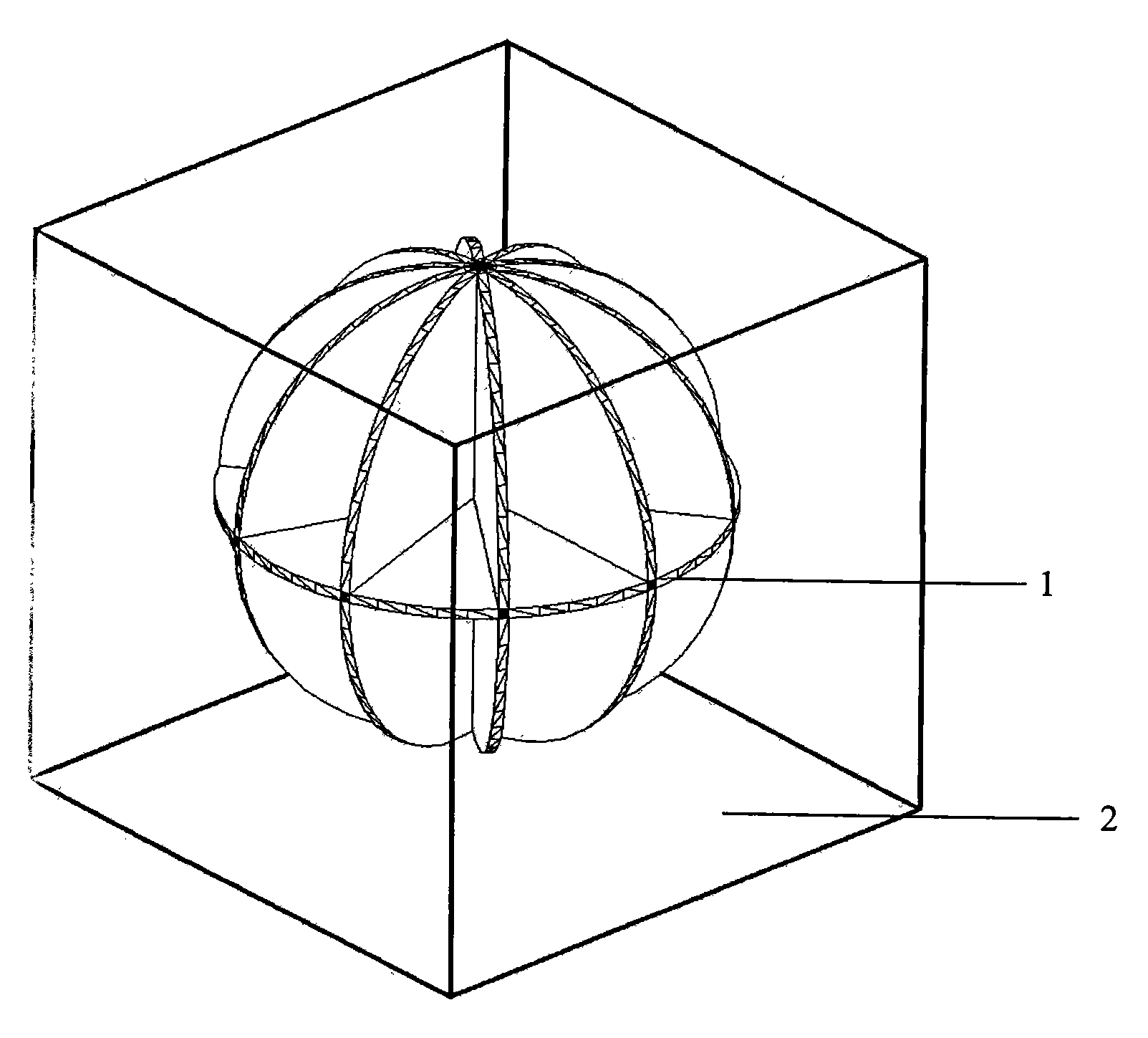

The invention discloses a rigid-flexible combined biological filler for biological trickling filtration deodorizing equipment and a preparation method thereof; the biological filler is formed by combining a rigid macromolecular skeleton at the center and flexible biological carrier porous medium at the periphery. During preparation, sustained-release control matter is firstly moistened by dispersing and lubricating liquid and evenly mixed with nutritive matter in an agitator, then macromolecular base material is moistened by the rest dispersing and lubricating liquid, added in the agitator and evenly stirred together with the mixture, the evenly mixed mixture is transferred in an injection machine and is extrusion molded by filler dies to prepare the rigid macromolecular skeleton; the rigid macromolecular skeleton is blended with polyether polyol, organic isocyanate, catalyst, external foaming agent, foam stabilizer and water, stirred at high speed and added into a forming box to finish chain growth, foam formation, cross linking and solidifying reaction, thus obtaining the biological filler. The filler of the invention has wide source of raw materials, convenient and simple manufacturing procedure, low production cost, and good film-forming and deodorizing effects.

Description

Rigid-flexible composite biofiller for biological trickling deodorization equipment and preparation method thereof technical field The invention relates to a biological filler used in malodorous gas treatment, in particular to a rigid-flexible composite biological filler for biological trickling deodorization equipment and a preparation method thereof. Background technique Odor pollution is one of the seven major environmental hazards in the world, and seeking reasonable treatment methods and control schemes has become a hot topic to be solved urgently in countries all over the world. Biological filter is a new technology for odor treatment that has received widespread attention in recent years. This technology has become the research topic of many countries because of its high treatment efficiency, no secondary pollution, simple equipment required, easy operation, low cost, and convenient management and maintenance. Hot spots are a development direction of odor control. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C02F3/10

CPCY02W10/10

Inventor 丁颖吴伟祥陈英旭胡斌

Owner ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com