Polylactic acid medical thin-film material with low plasticiser mobility and preparation method thereof

A technology for plasticizing polylactic acid and film materials, applied in medical science, surgery, etc., can solve the problems of complex polymer plasticizers, achieve the effects of reduced mobility, inhibited migration, and increased elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

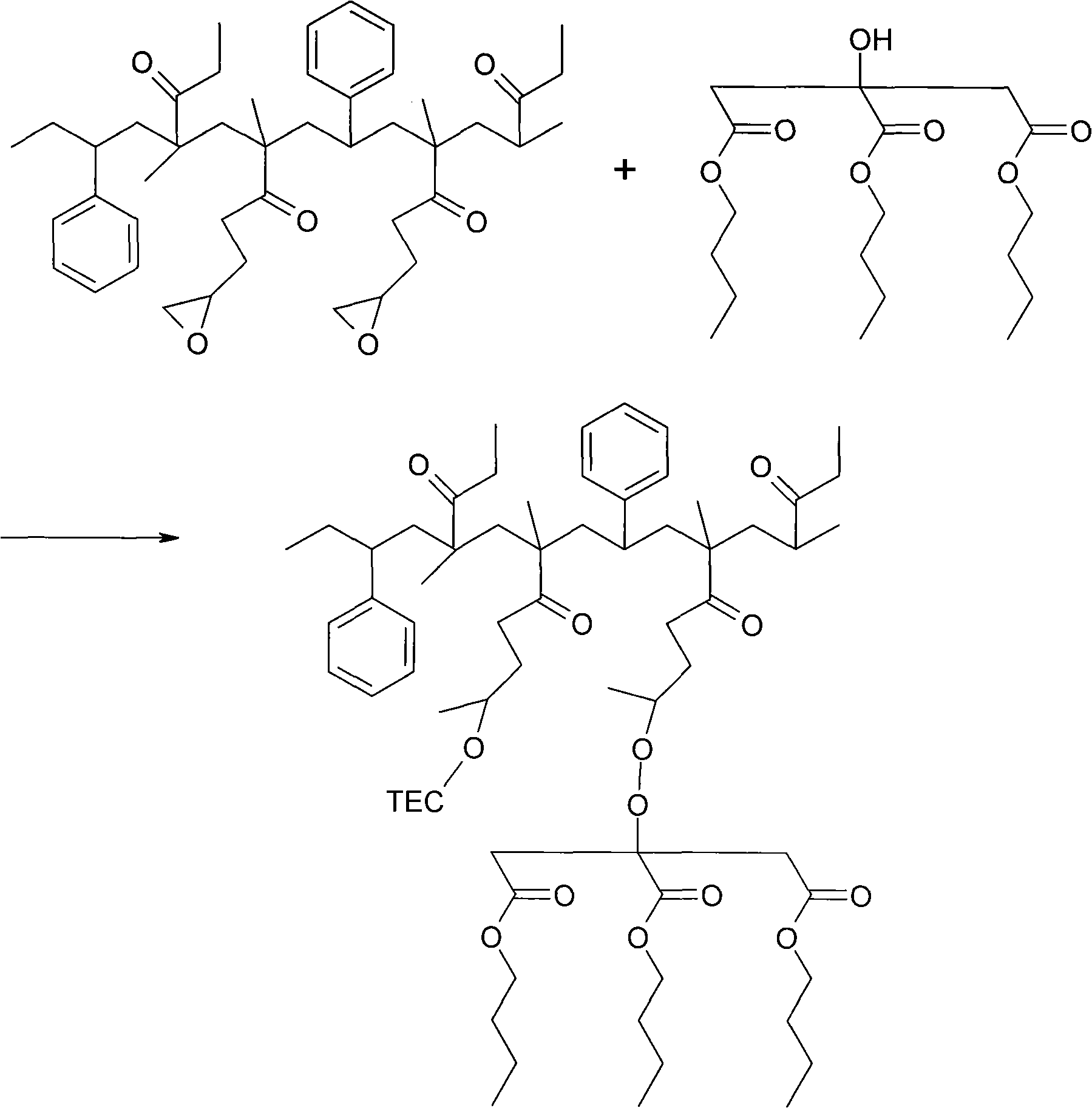

Method used

Image

Examples

Embodiment 1

[0031] Mix common medical plasticizer tri-n-butyl citrate (TEC) and chain extender J-ADR 4370S in a mass ratio of 100:0.5 in a reaction bottle, heat in an oil bath at 150°C, and accompany magnetic stirring for 2 hour, the reaction product obtained is the modified medical plasticizer; with 15 parts by weight of this modified medical plasticizer, 85 parts by weight of pure polylactic acid vacuum-dried in the torque rheometer, at 150 ℃, the rotating speed is Melt processing at 32rpm for 3 minutes, melt processing at 64rpm for 2 minutes, and then hot pressing at 160°C and 15MPa pressure for 5 minutes and cold pressing for 5 minutes in a hot press molding machine to form a thin plate. Its performance is shown in Table 1.

Embodiment 2

[0033] Common medical plasticizer tri-n-butyl citrate (TBC) and chain extender J-ADR 4370S were mixed in a reaction bottle at a mass ratio of 100:0.5, heated in an oil bath at 145°C, and accompanied by magnetic stirring for 2 hour, the reaction product obtained is the modified medical plasticizer; with 15 parts by weight of this modified medical plasticizer, 85 parts by weight of pure polylactic acid vacuum-dried in the torque rheometer, at 150 ℃, the rotating speed is Melt processing at 32rpm for 3 minutes, melt processing at 64rpm for 2 minutes, and then hot pressing at 160°C and 15MPa pressure for 5 minutes and cold pressing for 5 minutes in a hot press molding machine to form a thin plate. Its performance is shown in Table 1.

Embodiment 3

[0035] Common medical plasticizer tri-n-butyl citrate (TBC) and chain extender J-ADR 4368CS were mixed in a reaction bottle at a mass ratio of 100:0.6, heated in an oil bath at 145°C, and accompanied by magnetic stirring for 2 hour, the reaction product obtained is the modified medical plasticizer; with 15 parts by weight of this modified medical plasticizer, 85 parts by weight of pure polylactic acid vacuum-dried in the torque rheometer, at 150 ℃, the rotating speed is Melt processing at 32rpm for 3 minutes, melt processing at 64rpm for 2 minutes, and then hot pressing at 160°C and 15MPa pressure for 5 minutes and cold pressing for 5 minutes in a hot press molding machine to form a thin plate. Its performance is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com