Thermoplastic polyolefin photovoltaic waterproof coiled material and preparation method thereof

A technology of thermoplastic polyolefin and waterproof membrane, which is applied in photovoltaic power generation, climate sustainability, sustainable buildings, etc., can solve the problems of narrow temperature range of elastic performance and poor long-term weather resistance, so as to improve aging resistance and improve Waterproof performance, the effect of stabilizing the interpenetrating network structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

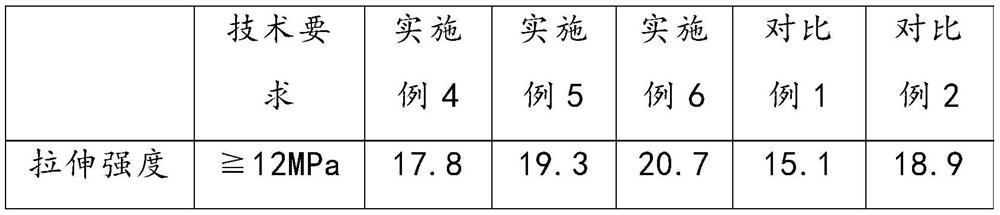

Examples

Embodiment 1

[0024] Preparation of light stabilizers:

[0025] After mixing 0.1mol 2,4-dihydroxybenzophenone, 0.13mol triethylamine and 60mL dichloromethane, at 0°C, slowly add 0.1mol acryloyl chloride dropwise, after the dropwise addition is complete, heat up to 10°C , stirred and reacted for 3h, then washed with water, separated the liquid, took the organic phase for recrystallization with methanol, and dried to obtain a light stabilizer.

Embodiment 2

[0027] The elastic material is made by the following steps:

[0028] The first step, after mixing 0.05mol hyperbranched polyester and 150mL dioxane evenly, turn on the condensed water, heat to 85°C, add 0.8mol methacrylic acid and 1.5g p-toluenesulfonic acid, stir and react for 6h, reduce to 50 ℃ decompression (-0.3MPa) rotary evaporation to obtain double bond-terminated hyperbranched polyester, wherein the hyperbranched polyester is hyperbranched polyester Boltorn H20;

[0029] In the second step, 0.28mol 3-mercaptopropylmethyldimethoxysilane, 0.75mol octamethylcyclotetrasiloxane and 0.01mol 1,1,3,3-tetramethyldisiloxane were added to the On the four-necked flask of mechanical stirring, thermometer, condenser and constant pressure funnel, slowly dropwise add the mixed solution of 1.1 g of trifluoromethanesulfonic acid and 0.23 mol of deionized water, after the dropwise addition, keep the temperature at 75 ° C to react until transparent , cooled to room temperature, washed by...

Embodiment 3

[0033] Preparation of elastic material:

[0034]The first step, after mixing 0.1 mol of hyperbranched polyester and 300 mL of dioxane, turn on the condensed water, heat to 90 ° C, add 1.6 mol of methacrylic acid and p-toluenesulfonic acid, stir and react for 8 hours, and then reduce to 50 ° C. Pressure (-0.3MPa) rotary evaporation to obtain double bond-terminated hyperbranched polyester, wherein, the hyperbranched polyester is hyperbranched polyester Boltorn H20, and its relative molecular mass is 1500-2000,

[0035] In the second step, 0.42mol 3-mercaptopropylmethyldimethoxysilane, 0.8mol octamethylcyclotetrasiloxane and 0.01mol 1,1,3,3-tetramethyldisiloxane were added to the On the four-necked flask of mechanical stirring, thermometer, condensation tube and constant pressure funnel, slowly add the mixed solution of 4.4g trifluoromethanesulfonic acid and 0.32mol deionized water dropwise, after the dropwise addition, keep the reaction at 75°C until transparent , cooled to roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com