Improved stability for coapplication

A co-copolymer technology, used in fiber processing, textiles and papermaking, can solve problems that have not been mentioned for use together

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

test approach 1-C

[0044] Test method 1-Cherry KOOL-AID staining test method (Stain Test Method)

[0045]Cherry KOOL-AID (KOOL-AID is a trademark of Kraft General Foods, Inc., White Plains NY) staining tests were performed on 15 cm x 15 cm carpet samples. Acid dye stain resistance was evaluated using a method based on American Association of Textile Chemists and Colorists (AATCC) Method 175, "Stain Resistance: Pile Floor Coverings." . The staining solution was prepared by mixing Cherry KOOL-AID sweetened with sugar (36.5 g) and 500 mL of water. Place the carpet sample to be tested on a flat, non-absorbent surface and place a 2 inch (5 cm) diameter hollow plastic cylinder tightly over the carpet sample. The KOOL-AID stain solution (20 mL) was injected into the cylinder that had been previously placed on the carpet sample. Work the stain evenly into the carpet. The cylinder was then removed and the stained carpet samples were left undisturbed for 24 hours. Then, rinse the carpet well under ...

test approach 4-

[0050] Test Method 4 - Mixture Stability

[0051] All mixtures of anti-stain agent, anti-stain agent, and co-application enhancer were judged by visual inspection as either stable mixtures (i.e., the formulation remained a homogeneous mixture) or unstable mixtures after the storage period indicated in each of the Examples and Comparative Examples (ie the formulation is not a homogeneous mixture).

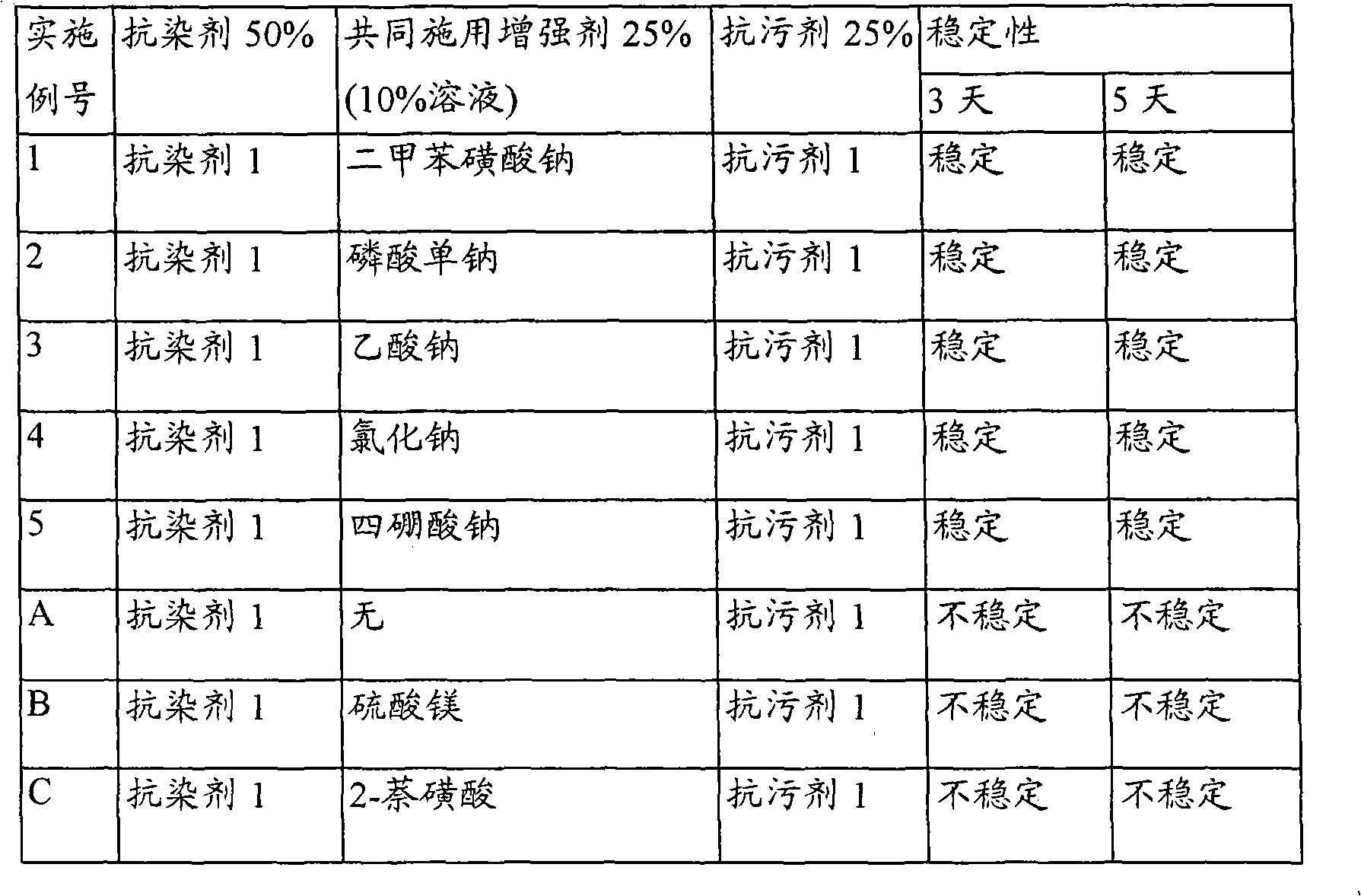

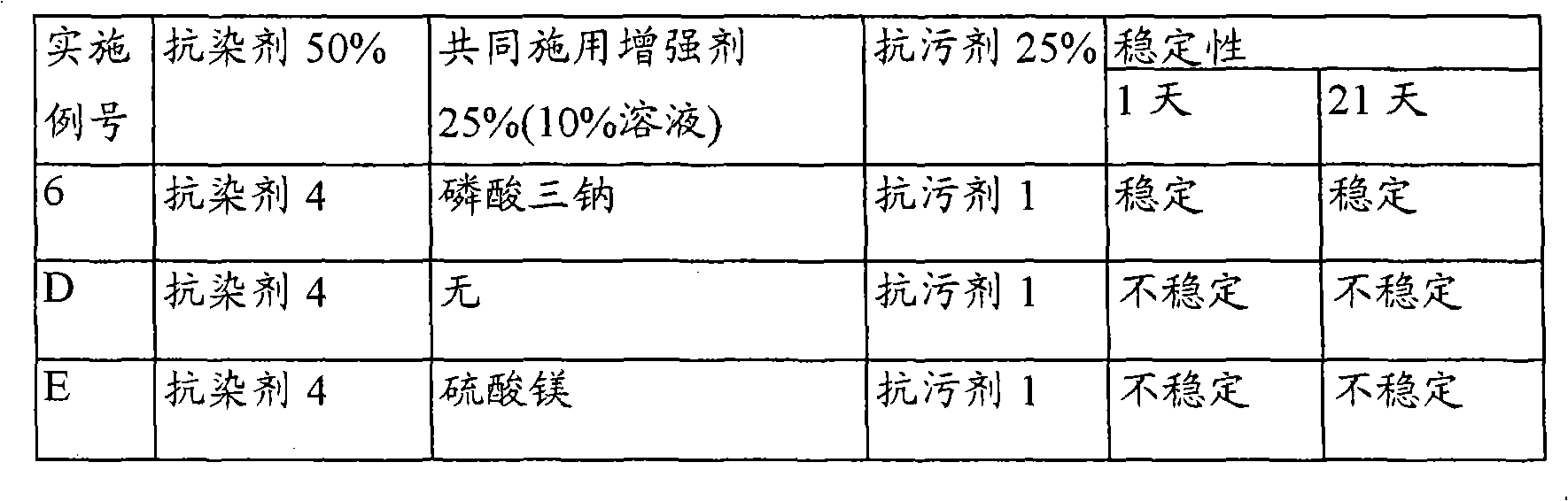

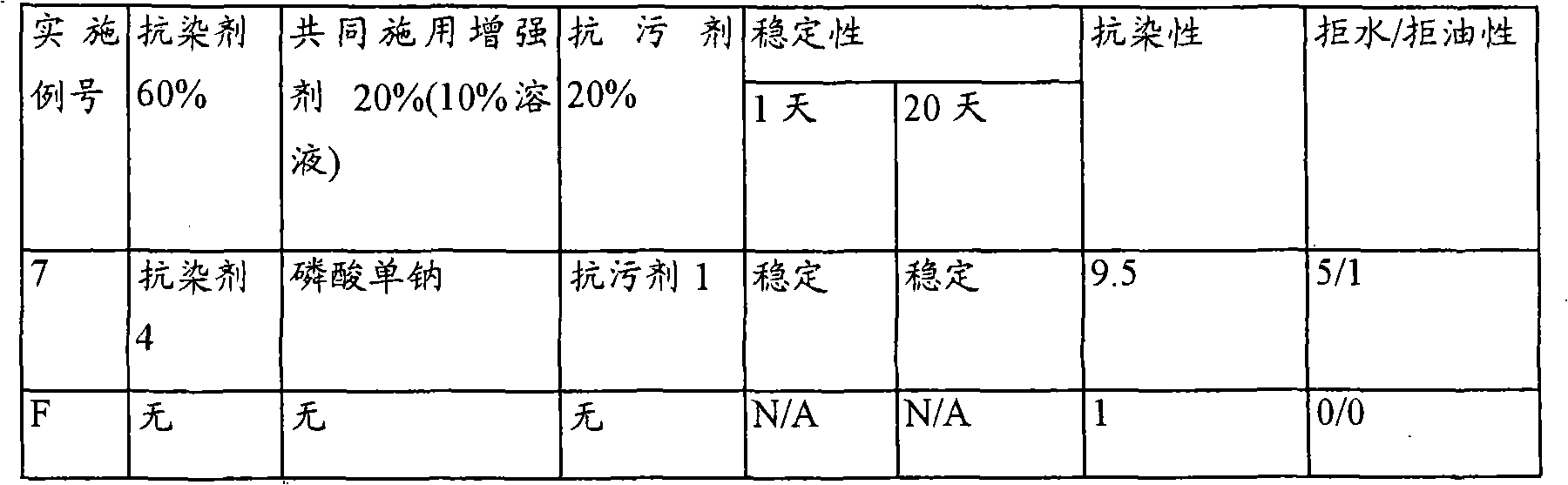

Embodiment 1-5

[0055] Concentrated mixtures of Examples 1-5 were prepared by physically mixing a mixture consisting of 50% Antistain 1, 25% of the 10% co-applied enhancer solution listed in Table 1, and 25% Antistain 1. The stability of the mixture was observed after 3 and 5 days (test method 4). The stability results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com