Non-bottom pillar deep hole falling-back type mining method

A mining method and retreat technology, applied in the field of deep hole retreat mining without bottom pillar, can solve the problems of many stopes, difficult safety, difficult production management, etc., and achieve uniform ore lumps, less auxiliary operations, The effect of high labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

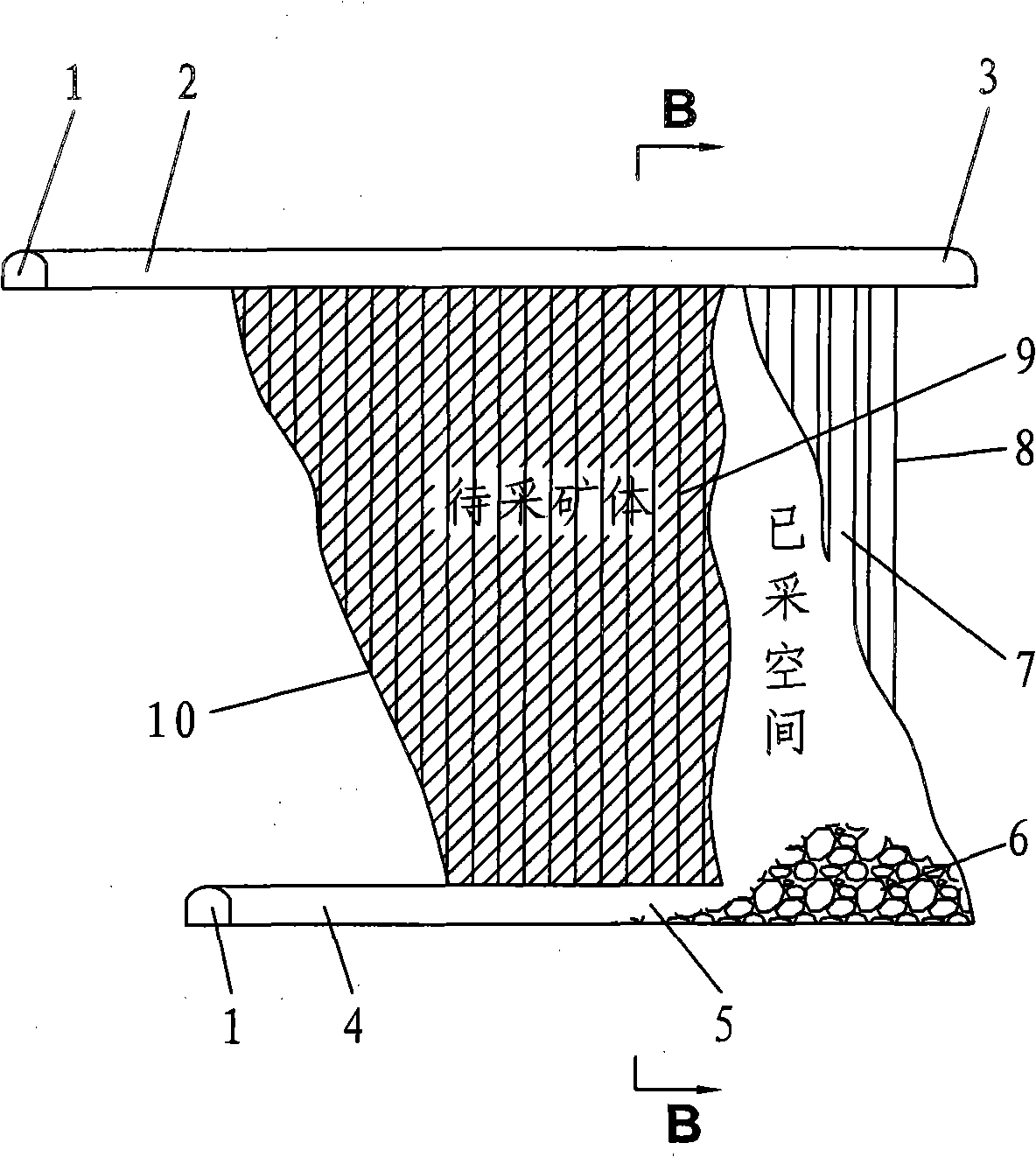

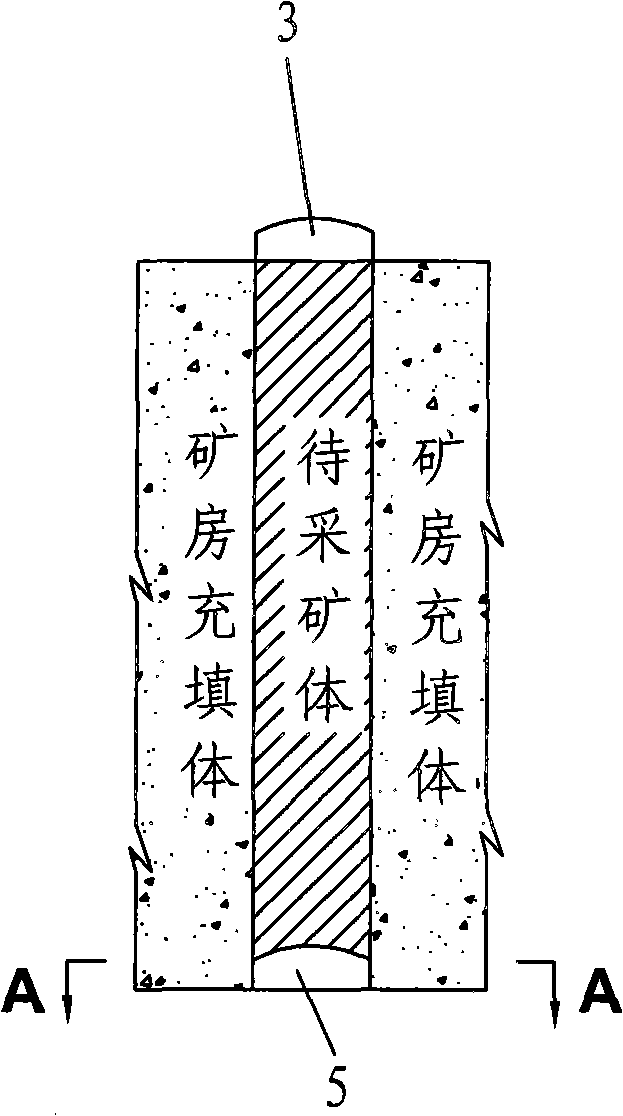

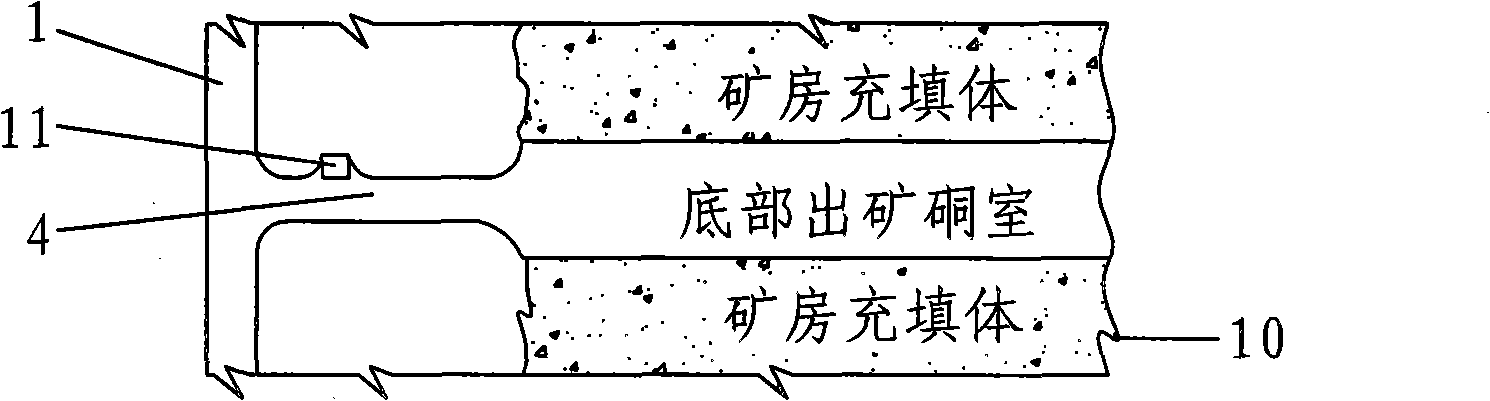

[0029] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0030]The mining area of the stope in the present invention reveals that the formation is the D3tb formation of the Tianziling Central Subgroup of the upper Devonian system, and the surrounding rocks are mostly composed of gray-black nodular limestone interbedded with thin interbedded marl, with nodular structures. The bedding is clear, and the compressive and shear strength of the rock is medium; its geological structure is: major ore-controlling faults can be seen in the mining area, of which the larger scale is NNE-trending F3, which is inclined to the east, and NE-trend F102, which is inclined to the west , the dip angle is between 70° and 80°, and it is a parallel right-shifting reverse fault. Both sides of the fault have obvious traction deflection. The range of the broken zone is about 0.5m to 1.5m. It is limestone, the cement is muddy or marl, relatively...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com