Method for rapidly preparing Ag/PPy composite material

A composite material, fast technology, applied in the field of preparation of Ag/PPy composite material, can solve problems such as slow kinetic speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

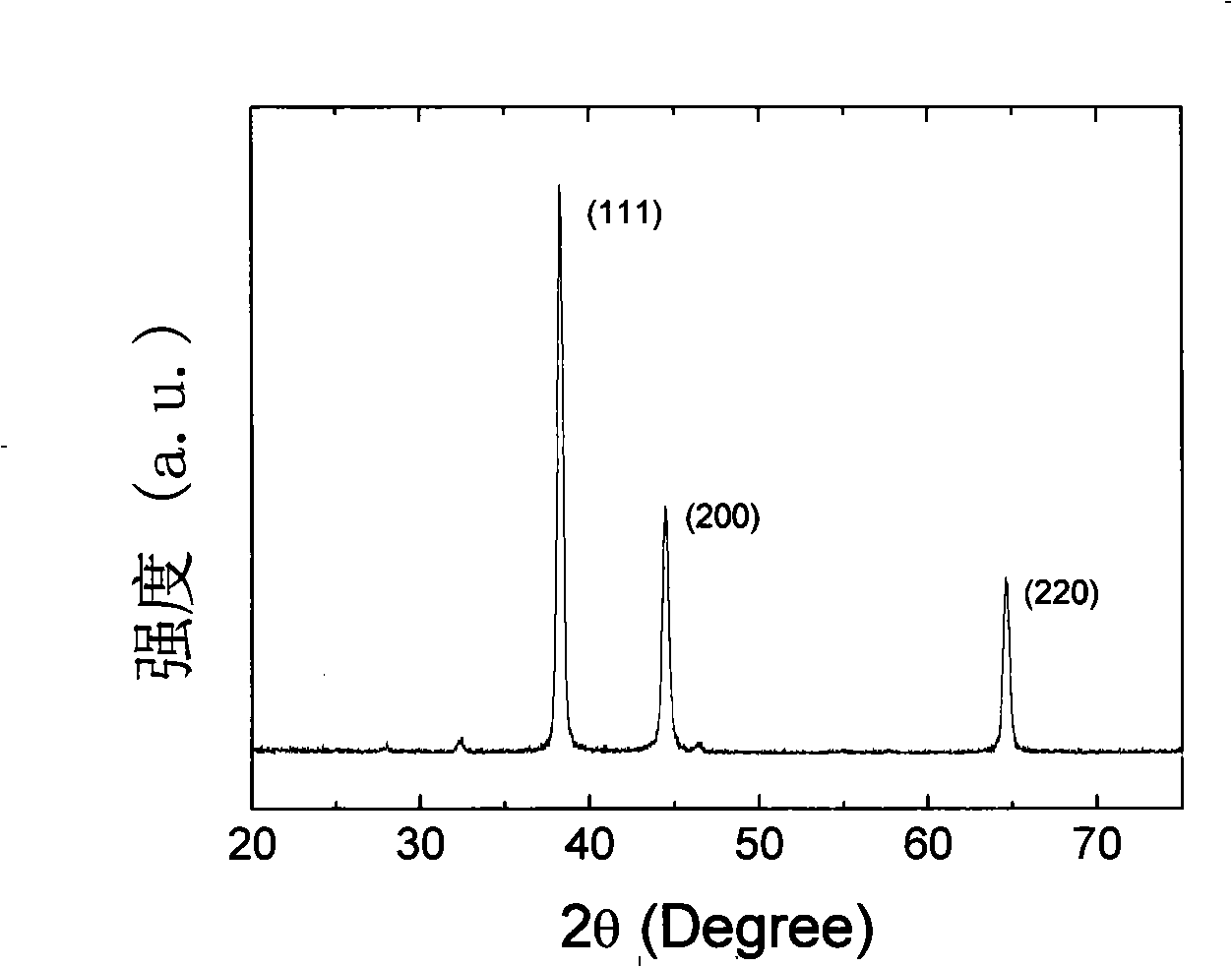

[0017] As in the above steps, a mixed solution of 0.5M silver nitrate + 0.7M pyrrole was selected, wherein DMF was used as a solvent. Add 30 μl of 15 M ammonia solution ([NH 4 + ] / [Ag + ]=0.9), and oscillated rapidly. It can be observed that within a few minutes, the solution becomes turbid and forms a black suspension, and a black film begins to form on the container wall; after 0.5 h, a solid black Ag / PPy composite film is formed on the container wall. The infrared spectrum and XRD of the black powder obtained in the container are respectively as follows figure 1 with figure 2 shown.

Embodiment 2

[0019] As in the above steps, a mixed solution of 0.5M silver nitrate + 0.70M pyrrole was selected, wherein DMF was used as a solvent. Add 60 μl of 15 M ammonia solution ([NH 4 + / [Ag + ]=1.8), and oscillated rapidly. It can be observed that within a few minutes, the solution becomes turbid and forms a black suspension, and a black film begins to form on the container wall; after 0.5 h, a solid black Ag / PPy composite film is formed on the container wall.

Embodiment 3

[0021] A mixed solution of 2.0M silver nitrate + 1.44M pyrrole was selected, wherein DMF was used as a solvent. Add 30 μl of 15 M ammonia solution ([NH 4 + / [Ag + ]=0.23), and oscillated rapidly. Then put it under dark conditions, and observe regularly to observe the change of the color of the solution. It can be observed that within a few minutes, the solution becomes turbid and forms a black suspension, and a black film begins to form on the container wall; after 0.5 h, a solid black Ag / PPy composite film is formed on the container wall, about 4 hours After that, a blue Ag / PPy composite sol was formed in the container.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com