Iron-copper based catalyst for synthesizing low carbon mixed alcohol and production method and use

A low-carbon mixed alcohol and catalyst technology, which is applied in the preparation of organic compounds, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of poor stability, low selectivity of total alcohol, high-grade Solve problems such as poor distribution of alcohol products, achieve good stability, simple preparation method, and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

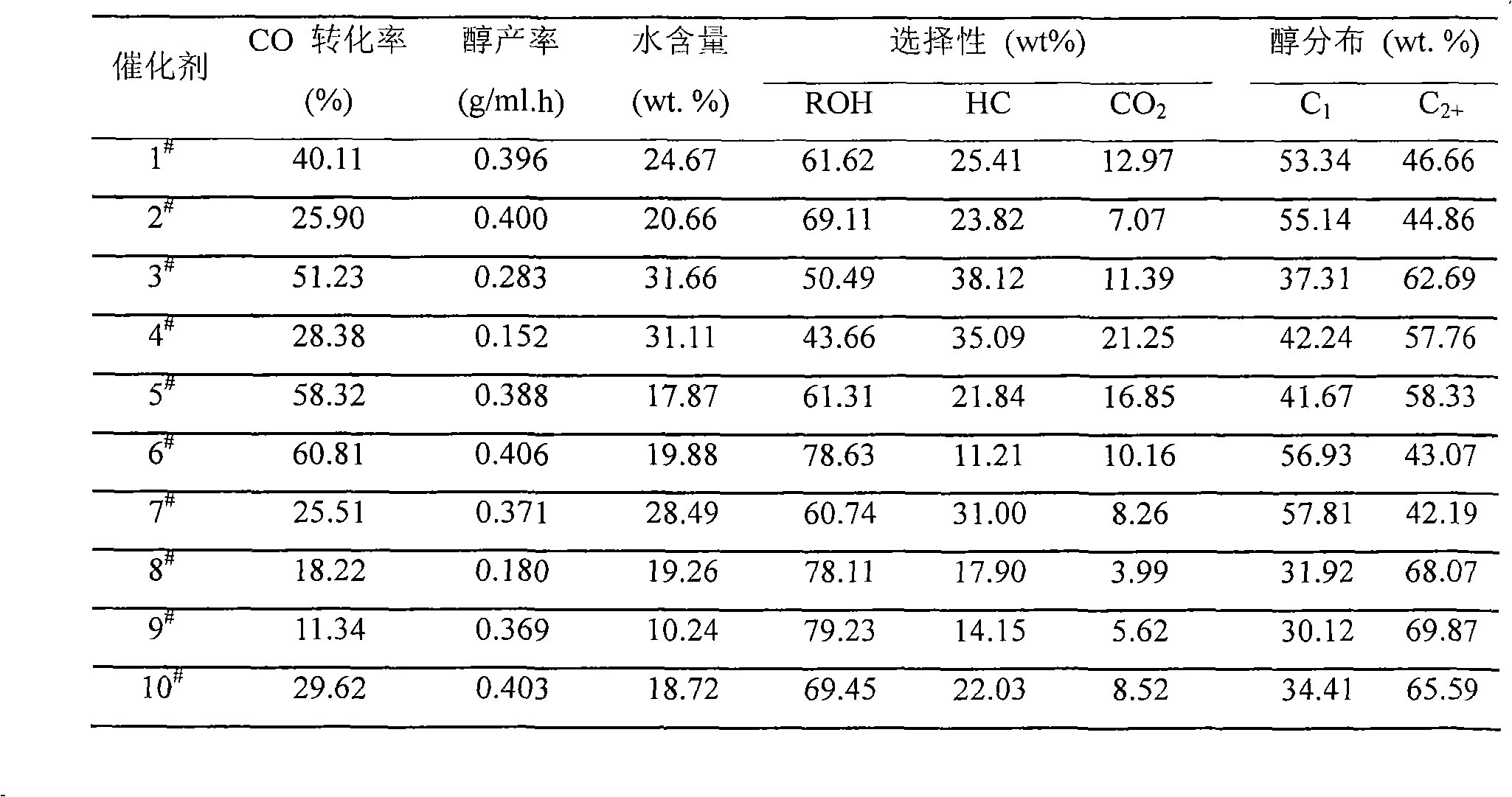

Embodiment 1

[0023] The following metal atoms in the form of nitrates were dissolved in distilled water at a molar ratio of Cu:Fe:Mn:Zn=1.0:1.0:0.5:0.2 to form a mixed solution. Co-precipitate with 30wt% sodium carbonate solution in co-current at 20°C, the precipitation process needs to be fully stirred, and the pH=9-10 should be maintained. The precipitate was washed with distilled water until neutral. After the wet filter cake is dried at 120°C, it is calcined at 350°C for 6 hours in an air atmosphere and crushed to 40-60 mesh. Dissolve 0.014 mol of lithium nitrate in distilled water, impregnate 10.0 g of the above-prepared sample with equal volumes of the aqueous solution of lithium nitrate, dry at 120°C, and roast at 550°C for 2 hours to obtain catalyst 1 # . The weight percent content of each metal is Cu: 39.18%, Fe: 34.44%, Mn: 16.93%, Zn: 8.09%, Li: 1.36%. At T=280℃, P=4.0MPa, GHSV=8000h -1 , H 2 / CO=2.0 reaction conditions, the results obtained are shown in Table 1.

Embodiment 2

[0025] The following metal atoms in the form of nitrates were dissolved in distilled water at a molar ratio of Cu:Fe:Mn:Zn=1.0:1.5:0.5:0.2 to form a mixed solution. Co-precipitate with 20wt% ammonia water at 60°C in parallel flow, the precipitation process needs to be fully stirred, and the pH=9-10 should be maintained. The precipitate was washed with distilled water until neutral. After the wet filter cake is dried at 60°C, it is calcined at 400°C for 6 hours in an air atmosphere and crushed to 40-60 mesh. Dissolve 0.0019 mol of potassium carbonate in distilled water, impregnate 10.0 g of the sample prepared above with equal volume of the potassium carbonate aqueous solution, dry at 60°C, and roast at 650°C for 1 hour to obtain catalyst 2 # . The weight percent content of each metal is Cu: 33.77%, Fe: 43.21%, Mn: 14.20%, Zn: 6.76%, K: 2.06%. At T=240℃, P=2.0MPa, GHSV=10000h -1 , H 2 / CO=0.5 reaction conditions, the results obtained are shown in Table 1.

Embodiment 3

[0027] The following metal atoms in the form of nitrates were dissolved in distilled water at a molar ratio of Cu:Fe:Mn:Zn=1.0:2.0:0.5:0.2 to form a mixed solution. Co-precipitate with 30wt% potassium carbonate in co-current at 60°C, the precipitation process needs to be fully stirred, and the pH=7-8 should be maintained. The precipitate was washed with distilled water until neutral. After the wet filter cake is dried at 120°C, it is calcined at 400°C for 6 hours in an air atmosphere and crushed to 40-60 mesh. Dissolve 0.0024 mol of cesium nitrate in distilled water, impregnate 10.0 g of the sample prepared above with an equal volume of the cesium nitrate aqueous solution, dry at 30°C, and calcinate at 450°C for 3 hours to obtain catalyst 3 #. The weight percentage content of each metal is Cu: 28.18%, Fe: 49.54%, Mn: 12.19%, Zn: 5.64%, Cs: 4.45%. At T=280℃, P=6.0MPa, GHSV=5000h -1 , H 2 / CO=2.0 reaction conditions, the results obtained are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com