Catalyst for jointly producing low carbon mixed alcohol and gasoline fraction from synthesis gas and production method and use

A low-carbon mixed alcohol and gasoline fraction technology, which is applied in the preparation of liquid hydrocarbon mixtures, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of high price and wide application of catalysts, etc. problem, to achieve the effect of low cost, good repeatability of reaction performance and good anti-sintering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

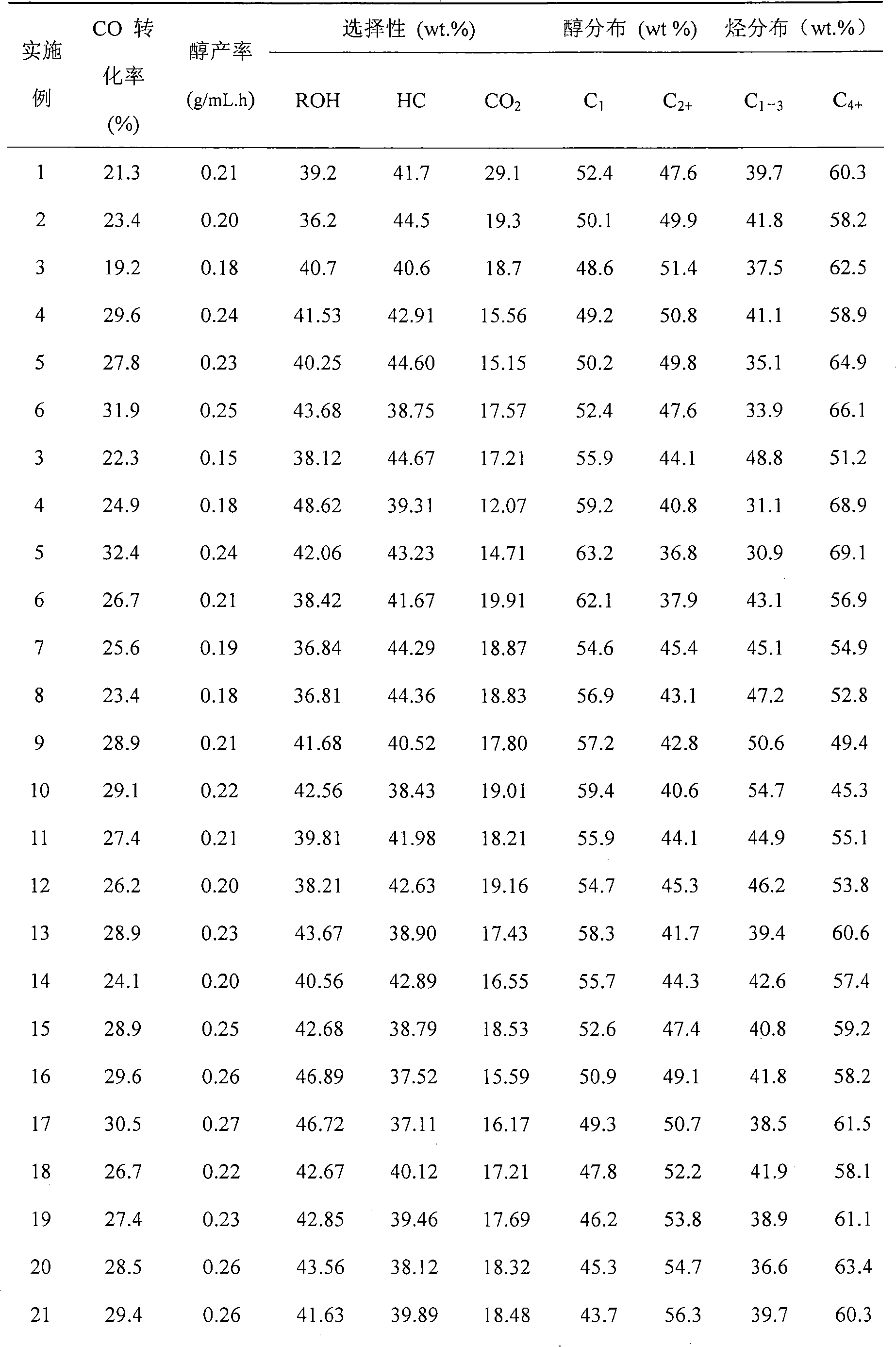

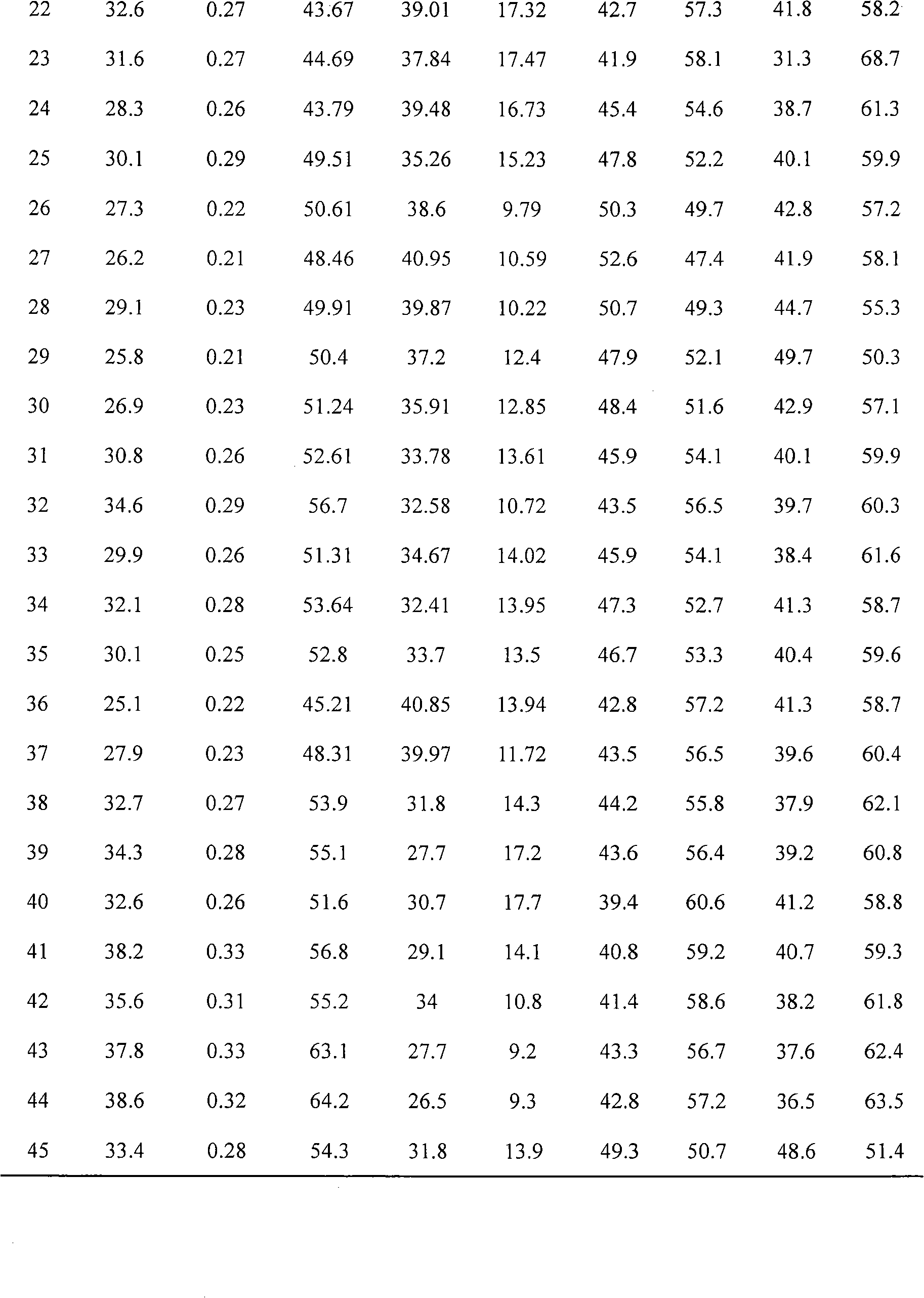

Embodiment 1

[0027] The following metal atoms in the form of nitrates were dissolved in distilled water at a molar ratio of Cu:Fe:Mn:Zn:Zr:Co=1.0:1.0:0.5:1:0.1:0.2 to form a mixed solution. Precipitate in parallel flow with 30wt% sodium carbonate solution at 70°C, fully stir during the precipitation process, and keep pH = 8-9. The precipitate was washed 30 times with an equal volume of distilled water. The wet filter cake was dried at 120°C, then calcined at 400°C in an air atmosphere for 6 hours, and crushed to 40-60 mesh to obtain the catalyst. The composition of each element in the catalyst is Cu: 25.2%, Fe: 24.8%, Mn: 8.7%, Zn: 24.8%, Zr: 6.8%, Co: 9.6%, Na: 0.05%. The reaction conditions are as follows: T=260°C, P=6.0MPa, GHSV=8000h -1 , H 2 / CO=2.0. The reaction results are shown in Table 1.

Embodiment 2

[0029] The following metal atoms in the form of nitrates were dissolved in distilled water at a molar ratio of Cu:Fe:Mn:Zn:Zr:Co=1.0:1.0:0.5:1:0.1:0.2 to form a mixed solution. Precipitate in parallel flow with 30wt% sodium carbonate solution at 70°C, fully stir during the precipitation process, and keep pH = 8-9. The precipitate was washed 15 times with an equal volume of distilled water. The wet filter cake was dried at 120°C, then calcined at 400°C in an air atmosphere for 6 hours, and crushed to 40-60 mesh to obtain the catalyst. The composition of each element in the catalyst is Cu: 25.2%, Fe: 23.8%, Mn: 8.7%, Zn: 24.8%, Zr: 6.8%, Co: 9.6%, Na: 1.1%. The reaction conditions are as follows: T=260°C, P=6.0MPa, GHSV=8000h -1 , H 2 / CO=2.0. The reaction results are shown in Table 1.

Embodiment 3

[0031] The following metal atoms in the form of nitrates were dissolved in distilled water at a molar ratio of Cu:Fe:Mn:Zn:Zr:Co=1.0:1.0:0.5:1:0.1:0.2 to form a mixed solution. Precipitate in parallel flow with 30wt% sodium carbonate solution at 70°C, fully stir during the precipitation process, and keep pH = 8-9. The precipitate was washed 5 times with an equal volume of distilled water. The wet filter cake was dried at 120°C and then calcined at 400°C for 6 hours in an air atmosphere and crushed to 40-60 mesh to obtain the catalyst. The composition of each element in the catalyst is Cu: 26.2%, Fe: 24.8%, Mn: 8.7%, Zn: 24.8%, Zr: 7.8%, Co: 9.6%, Na: 4.1%. The reaction conditions are as follows: T=260°C, P=6.0MPa, GHSV=8000h -1 , H 2 / CO=2.0. The reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com