Compacted magnetic core, production method of the same, and motor for electric vehicle

A manufacturing method and technology of magnetic cores, which are used in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve the problems of Mg powder coating, insufficient resistance value, time-consuming, etc., and achieve high heat resistance. The effect of high resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

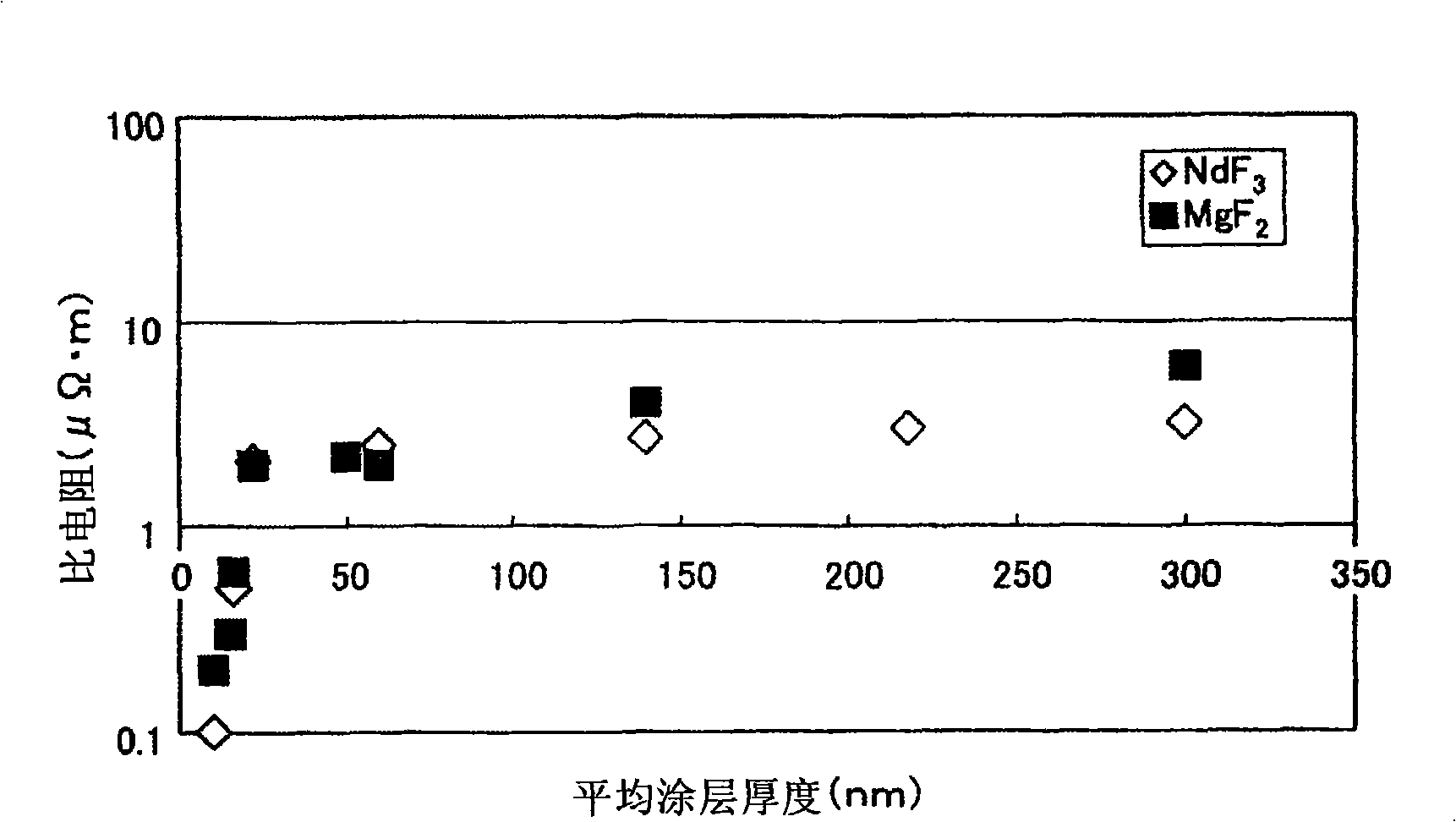

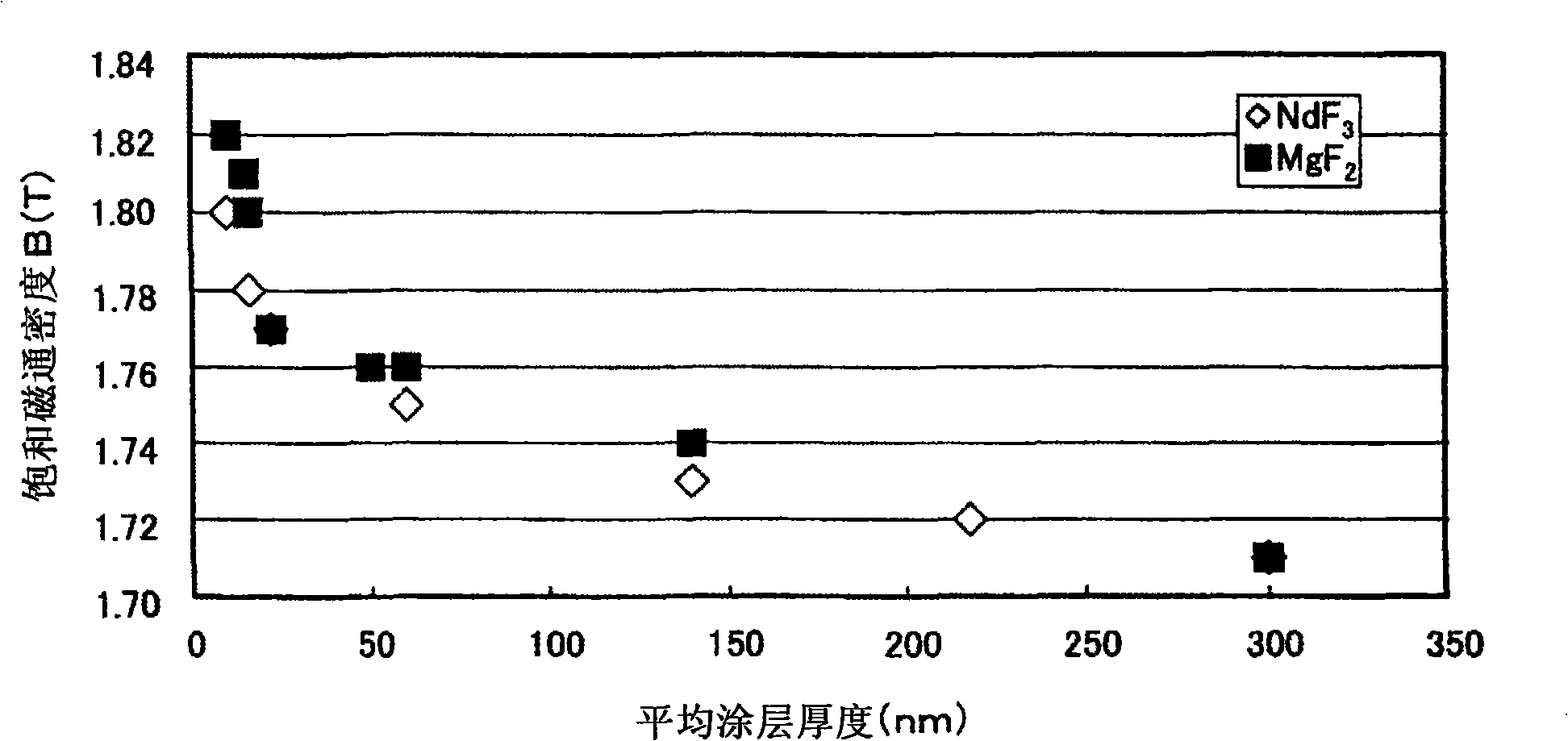

[0058] Use gas atomized iron powder with a particle size of 100μm.

[0059] Compared with iron powder, 30nm MgF is formed 2 Coating film, measuring specific resistance and ring.

[0060] The specific resistance is 50μΩ·m. According to the ring measurement, the saturation magnetic flux density B is 1.76T and the loss is 37W / kg. Also, NdF with the same film thickness 3 The loss in the coating film is 80W / kg.

Embodiment 2

[0062] As the soft magnetic powder, water atomized iron powder with a diameter of 70μm is used, and it is processed by a ball mill together with SUS balls. The iron powder protrusions were removed by a 30-minute treatment.

[0063] Compared with iron powder, 50nm MgF is formed 2 Coating film, measuring specific resistance and ring.

[0064] The specific resistance is 70μΩ·m. According to the ring measurement, the saturation magnetic flux density B is 1.75T, and the loss is 45W / kg.

Embodiment 3

[0066] Reduced iron powder with an average particle size of 120 μm is used.

[0067] Compared with iron powder, it forms 100nm MgF 2 Coating film, measuring specific resistance and ring.

[0068] The specific resistance is 250 μΩ·m. According to the ring measurement, the saturation magnetic flux density B is 1.7T and the loss is 47W / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com