System and method for positioning split joint wall based on image inductor

An image sensor and positioning system technology, which is applied in the input/output process of instruments, data processing, electrical digital data processing, etc., can solve the problem of slow refresh rate and inability to meet the large-size and high-precision positioning requirements of large-screen splicing walls , Infrared long-distance receiving effect is poor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

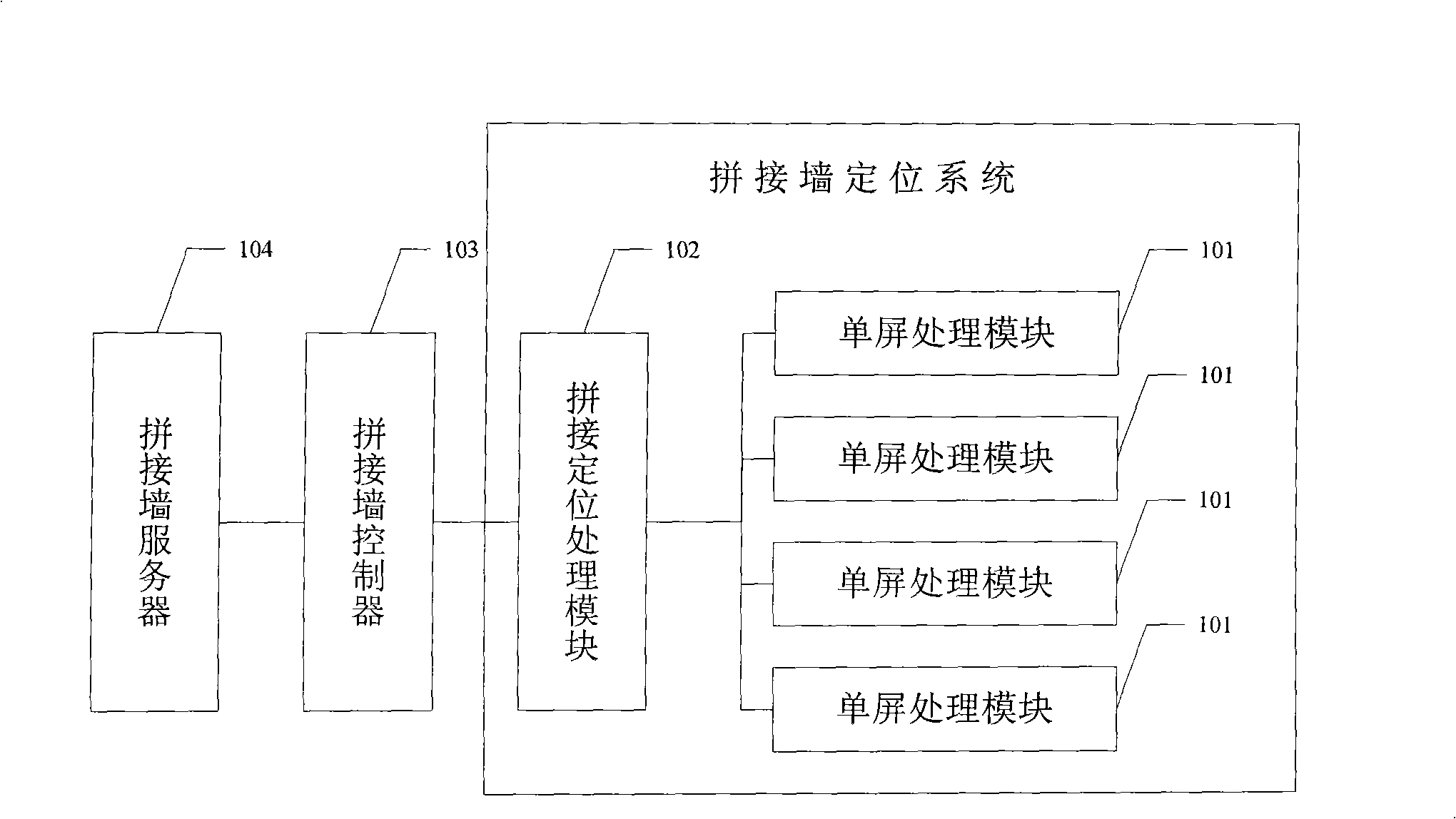

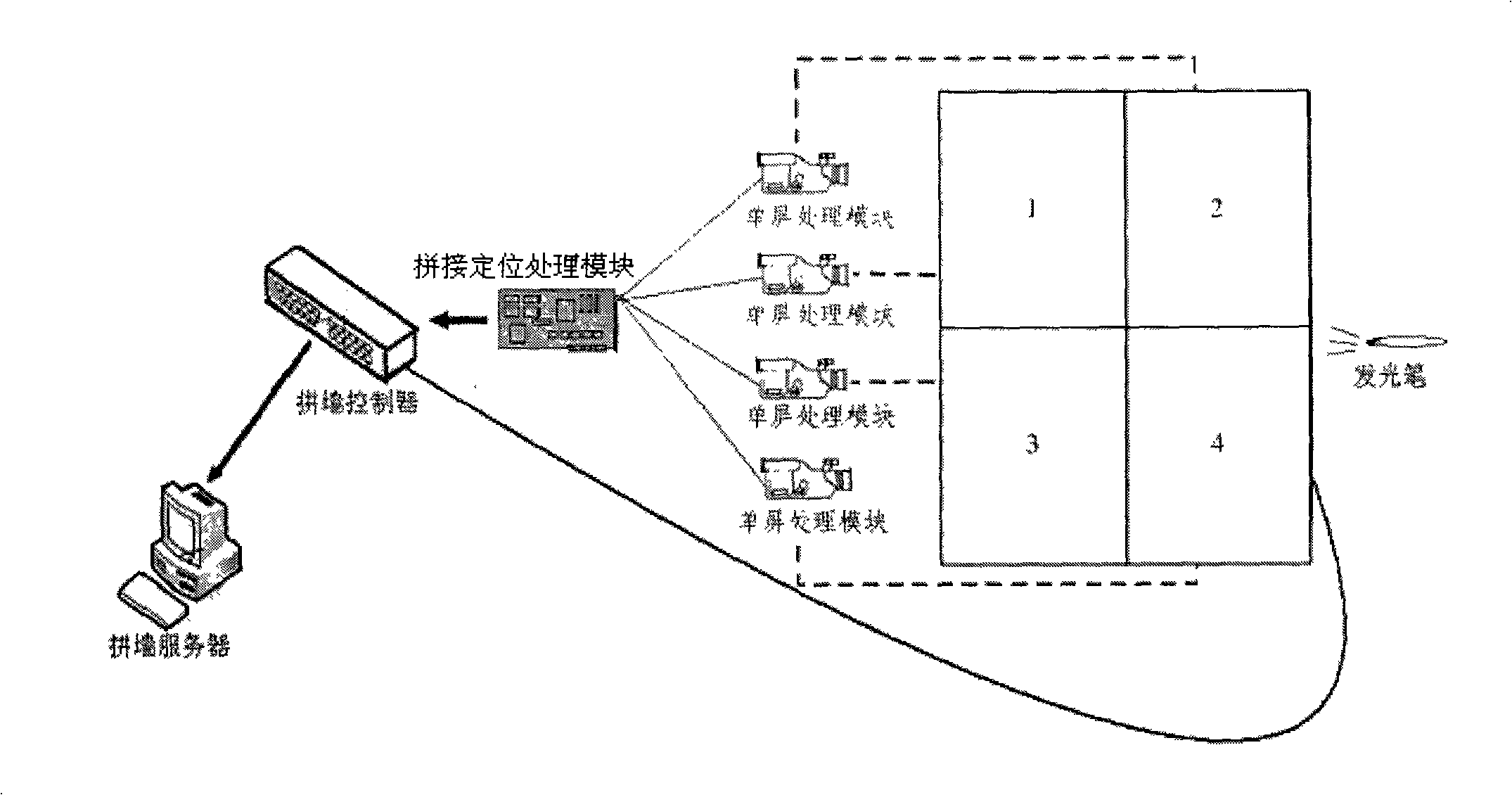

[0027] Such as figure 1 As shown, it is a schematic structural diagram of the video wall positioning system based on the image sensor of the present invention, figure 2 Shown is a schematic diagram of the composition of the positioning system.

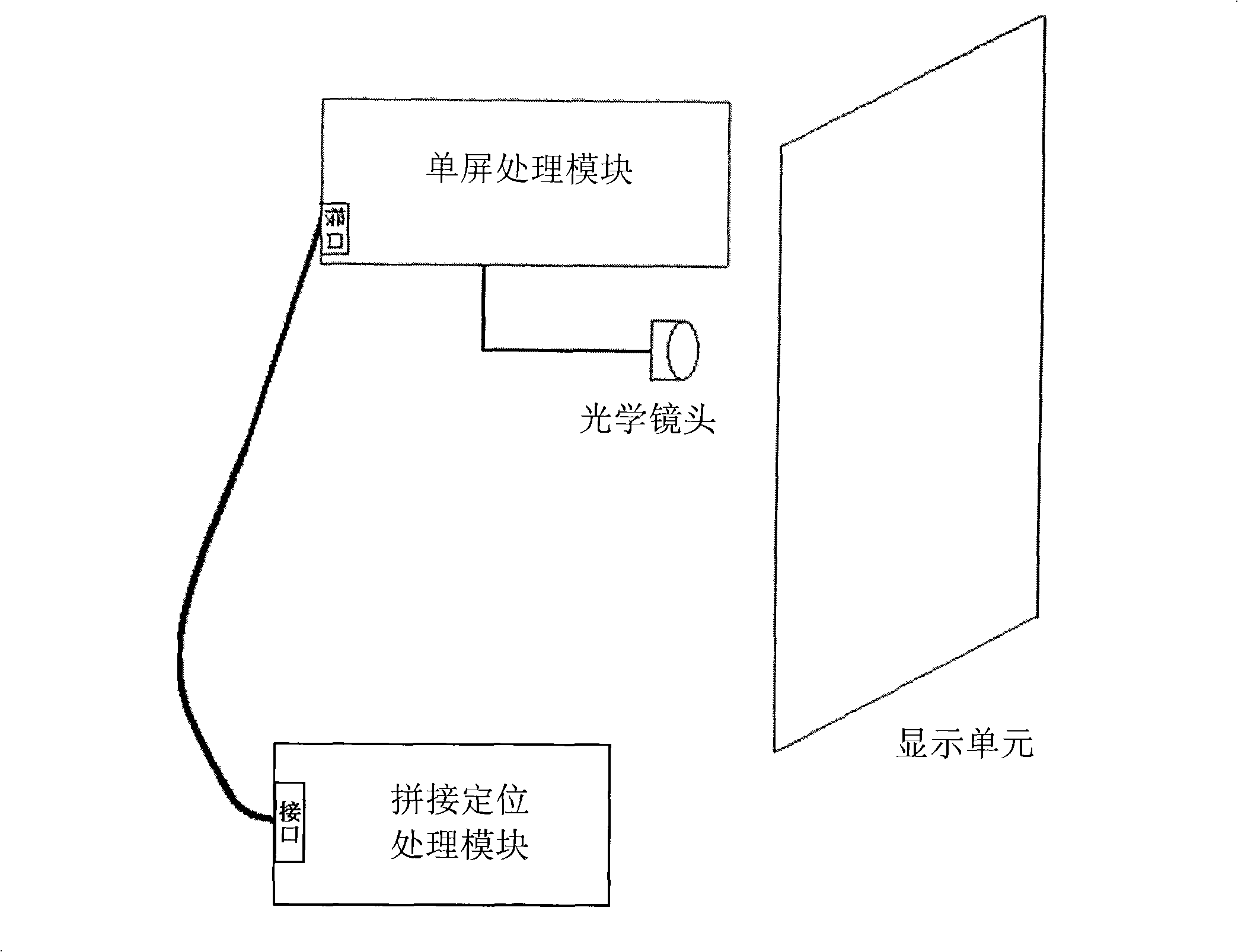

[0028] Such as figure 1 As shown, it is a schematic structural diagram of the video wall positioning system based on the image sensor of the present invention, which includes at least two or more single-screen processing modules 101 and a splicing positioning processing module connected to the single-screen processing modules 101 102, wherein any single-screen processing module 101 corresponds to one of the display units of the splicing wall;

[0029] The single-screen processing module 101 is configured to collect the luminance value of each pixel of the display unit, and perform binarization processing on the luminance value of each pixel according to a preset pixel threshold, and calculate the brightness value of each pixel in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com