High definition mechanical system of pipe leakage detector

A high-definition, mechanical system technology, used in radio wave measurement systems, instruments, measurement devices, etc., can solve the problems of insufficient detection accuracy, insufficient information collection, and low dynamic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

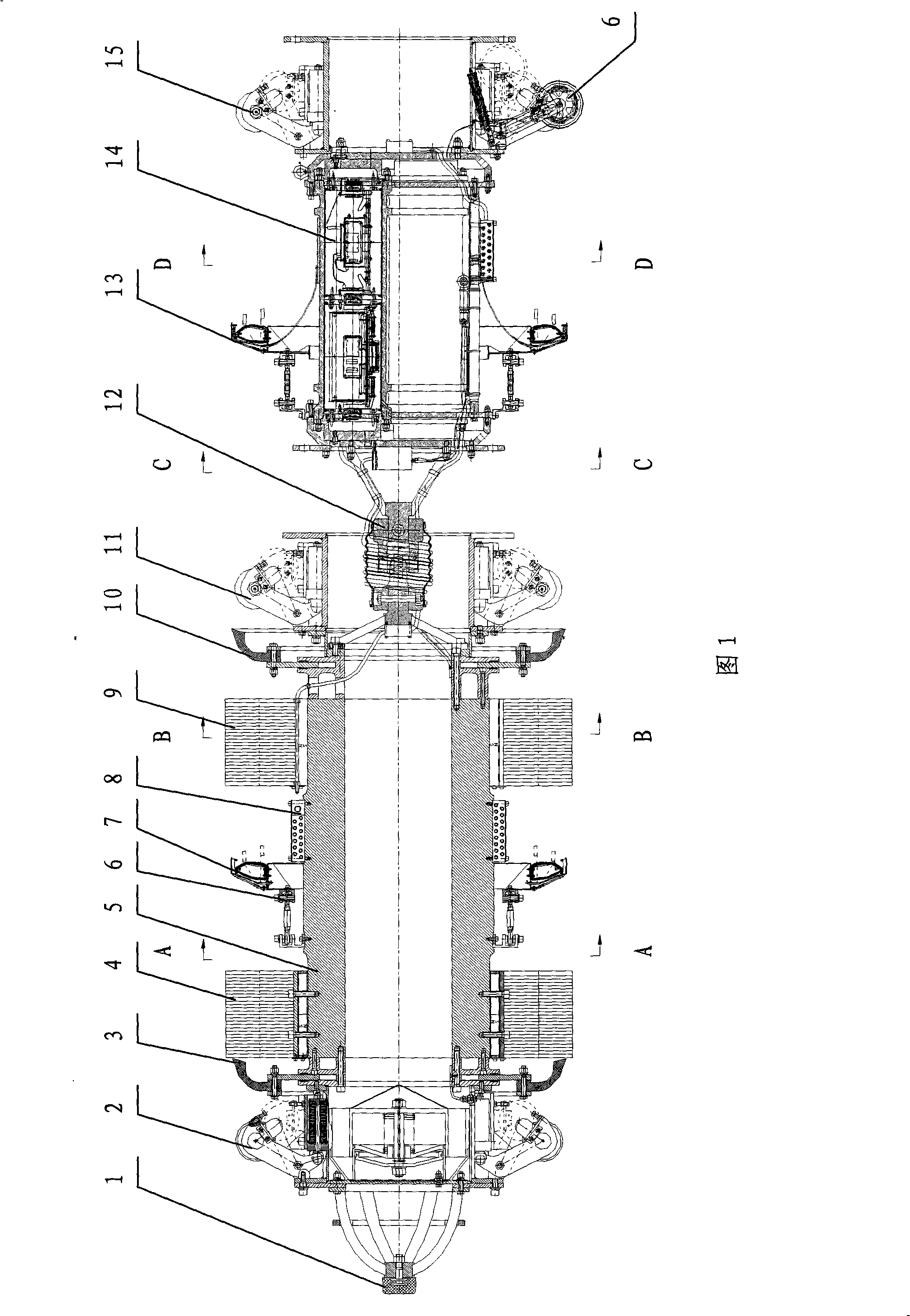

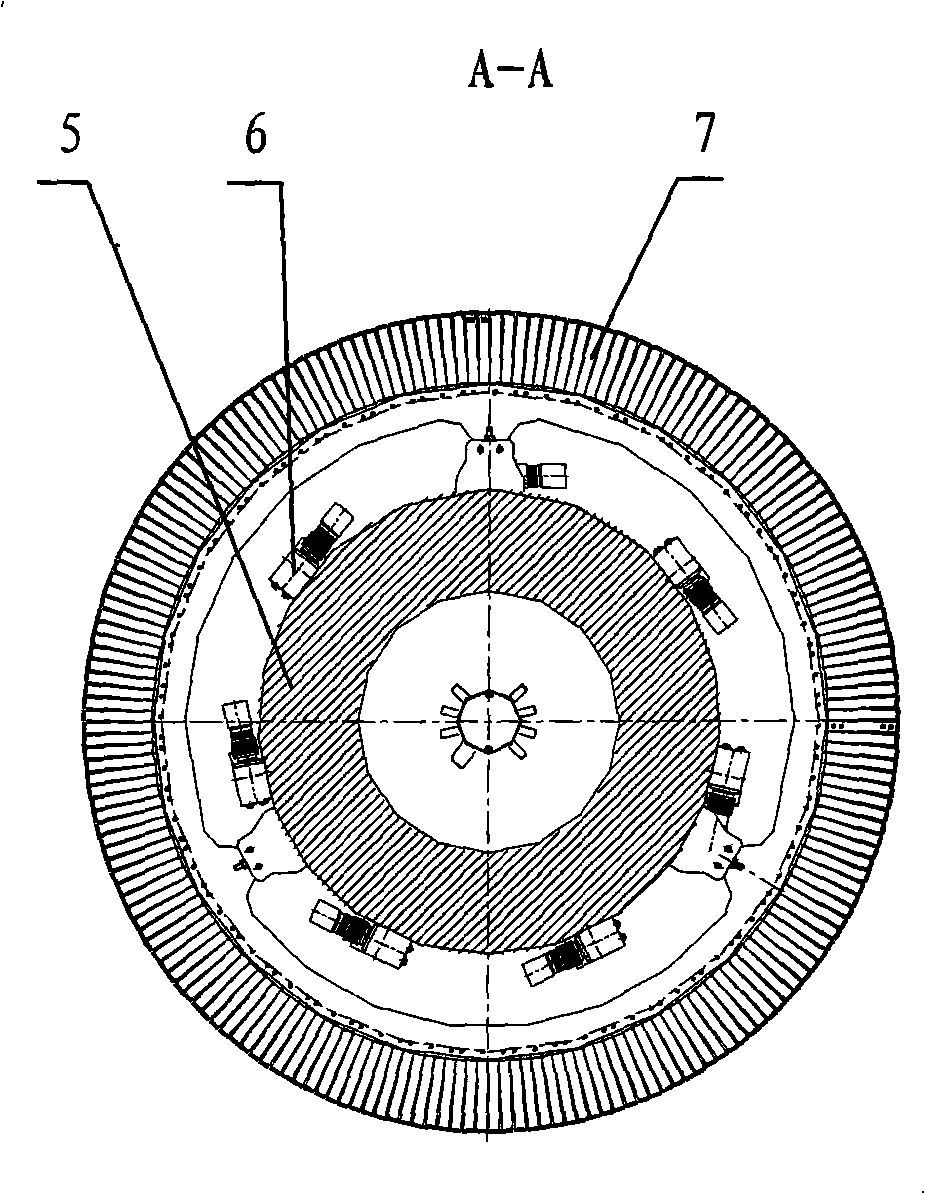

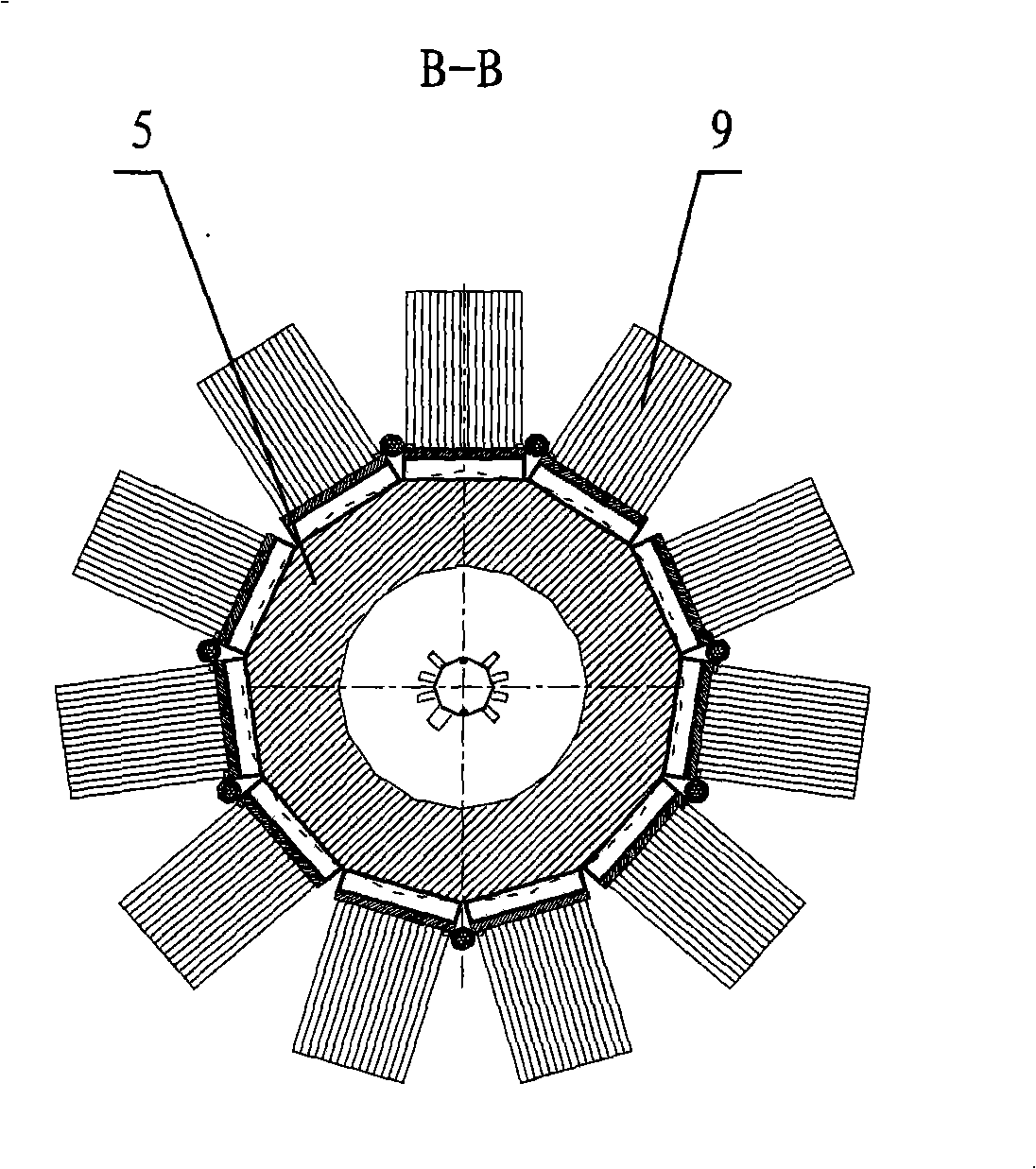

[0074] Embodiment. The specific embodiment of the present invention is described with this example and the present invention is described further. This example is the mechanical system of the experimental prototype of the Φ1016mm high-definition pipeline magnetic flux leakage detector, and its composition is shown in Figure 1, figure 2 , image 3 shown. The total weight of the detector is 2857kg, supporting wheels (see Image 6 , Figure 7 , Figure 8 ) main dimensions: total height 285mm, total length 264mm, total width 197mm; wheel 39: Φ125mm, thickness 100mm, axle 50Φ30mm, length 140mm; disc spring 23 length 134mm, Φ50mm, (d=18.4t=3 h=4.4 material 60S12MnA) rigidity 666N / mm; Anti-collision block (1) 21 and anti-collision block (2) 41 are made of polyester. Nut 35 and nut 43 are non-metallic inserts made of A2-70 material

[0075] Floating drive cup: Cup 72 bowl side outer diameter ∮1016.6mm, thickness 36.1mm, inner diameter ∮715mm, made of polyurethane material into i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com