Press forming and processing method for saving motor stator and rotor material as well as device

A motor stator and stamping processing technology, applied in the field of mechanical processing, can solve problems such as waste, achieve the effects of reducing waste, high-speed continuous production, and improving material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

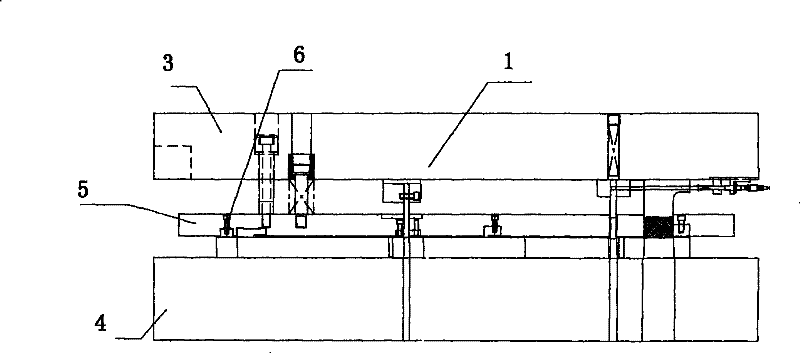

[0025] Embodiment 1: as figure 1 Shown, mold comprises upper mold base 3, lower mold base 4, guide plate 5, screw 6, and guide plate 5 is installed between upper mold base 3 and lower mold base 4, is fixed on the lower mold base 4 by screw 6.

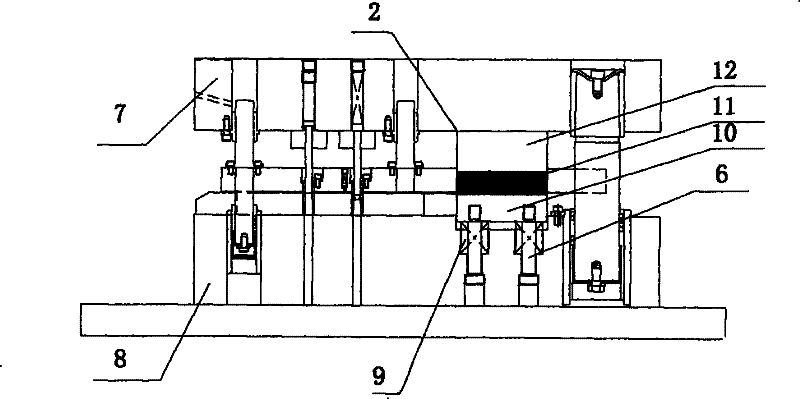

[0026] Such as figure 2 As shown, the mold includes an upper mold holder 7, a lower mold holder 8, an elastic body 9, a supporting plate 10, a punch 11, a pad 12, and a screw 6, and the lower mold fixing base 8 is equipped with a supporting plate 10, and the supporting plate 10 Elastomer 9 is housed between lower mold holder 8, fixed by screw 6, punch 11 is housed on the supporting plate 10, pad 12 is housed on the punch 11.

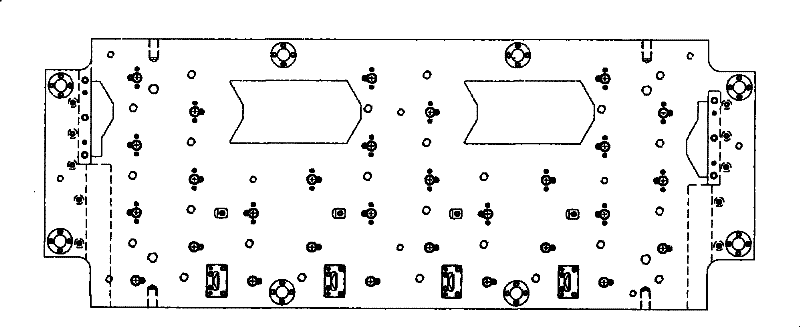

[0027] Such as image 3 As shown, the mold has stamping wavy edges and punching and cutting punches and dies for each column.

Embodiment 2

[0028] Embodiment 2: A stamping process method for motor stator and rotor materials, comprising the following steps:

[0029] Step 1: Stator and rotor stamping dies are generally single-row or double-row, and the number of stamping rows for wave-shaped materials (based on 1200-1250MM large coil materials) is determined according to single-row or double-row;

[0030] Figure 8 with Figure 9 It is a schematic diagram and comparison between the layout of the stamped workpiece in the present invention and the traditional layout.

[0031] Such as Figure 8 The determined number of columns is 2, and the edge is 1.5MM, and the positions of the workpieces to be stamped are arranged in a cross, such as Figure 8 As shown, according to the 1210MM wide material design, the raw materials can be fully utilized.

[0032] Figure 8 Take the strip width of 1210mm as an example: in the case of the same strip width, Figure 8 The method of punching flower material can punch out 5 flower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com