Press forming and processing method for saving motor stator and rotor material as well as device

A motor stator and stamping processing technology, which is applied in the field of mechanical processing, can solve problems such as waste, and achieve the effects of reducing waste, improving material utilization, and high-speed continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

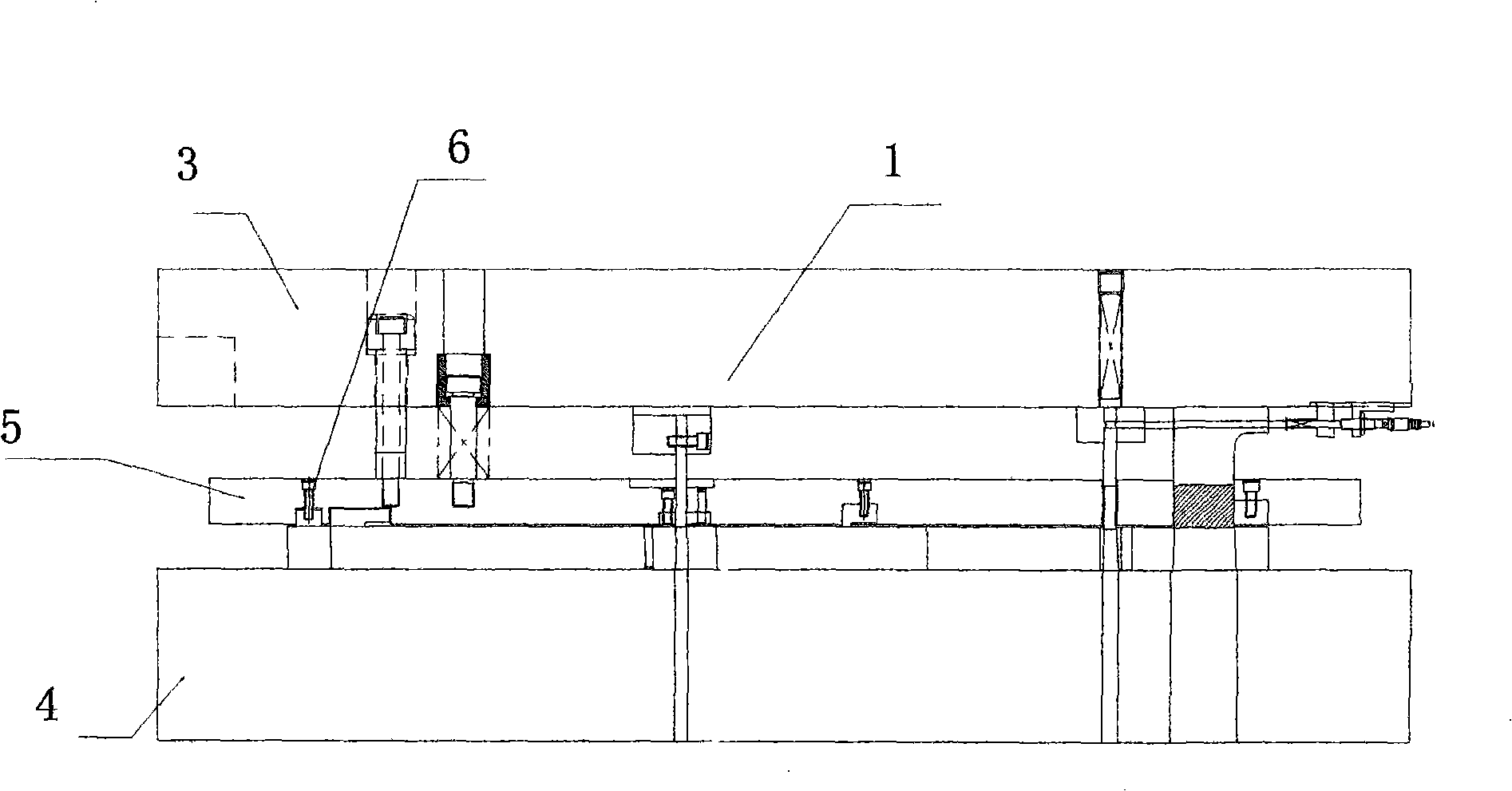

[0025] Embodiment 1: as figure 1 Shown, mold comprises upper mold base 3, lower mold base 4, guide plate 5, screw 6, and guide plate 5 is installed between upper mold base 3 and lower mold base 4, is fixed on the lower mold base 4 by screw 6.

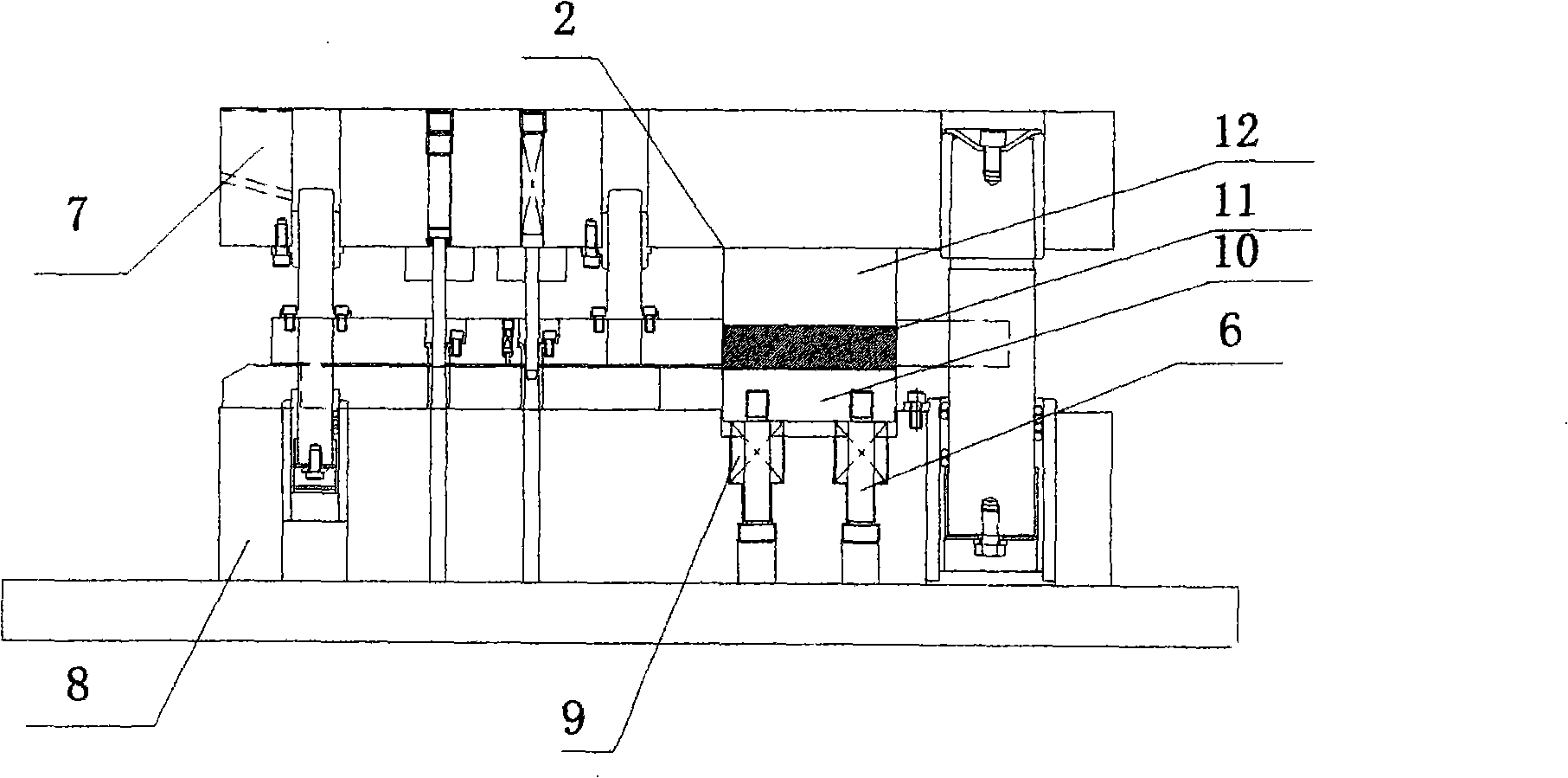

[0026] like figure 2 As shown, the mold includes an upper mold holder 7, a lower mold holder 8, an elastic body 9, a supporting plate 10, a punch 11, a pad 12, and a screw 6, and the lower mold fixing base 8 is equipped with a supporting plate 10, and the supporting plate 10 Elastomer 9 is housed between lower mold holder 8, fixed by screw 6, punch 11 is housed on the supporting plate 10, pad 12 is housed on the punch 11.

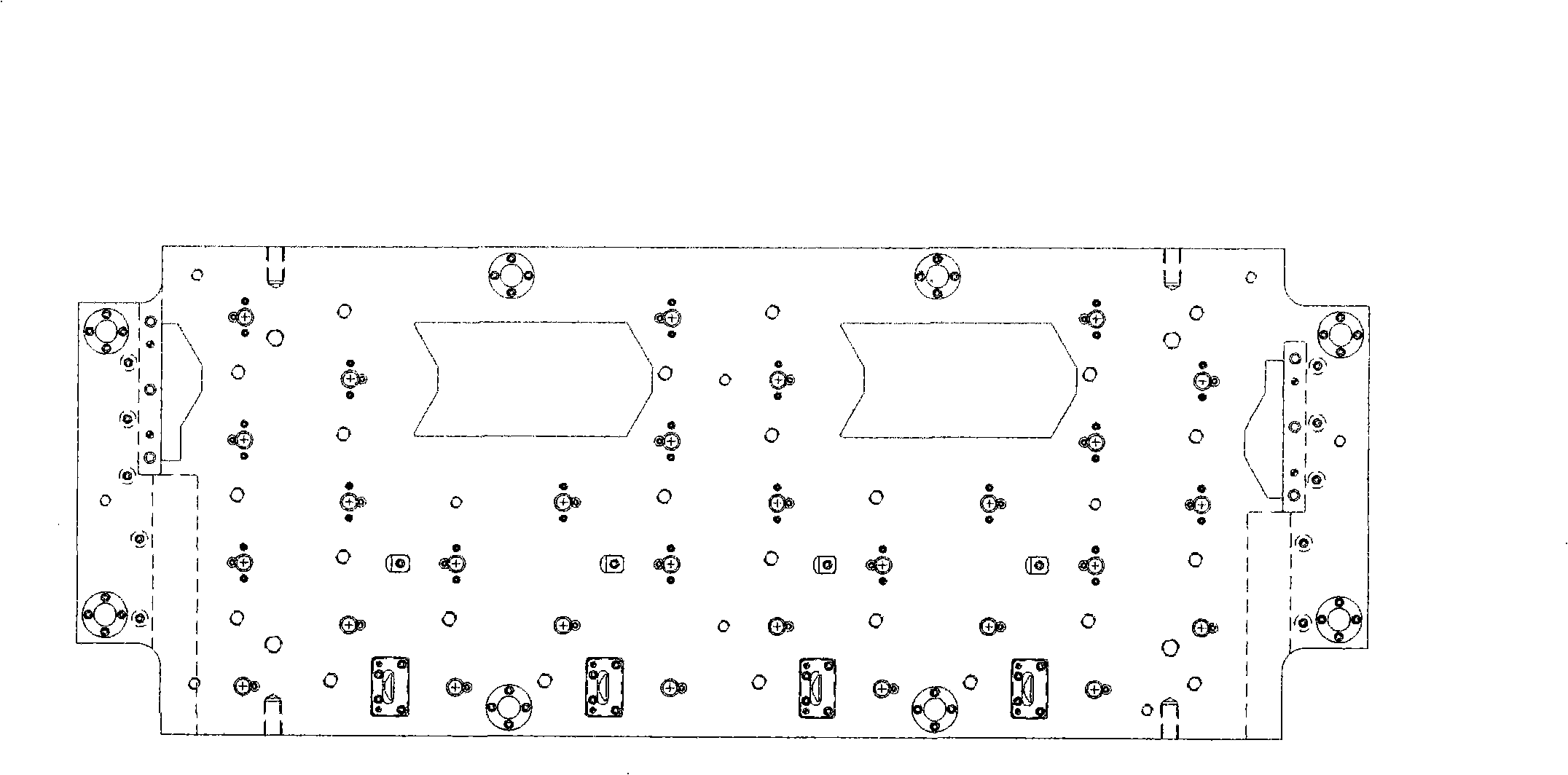

[0027] like image 3 As shown, the mold has stamping wavy edges and punching and cutting punches and dies for each column.

Embodiment 2

[0028] Embodiment 2: A stamping process method for motor stator and rotor materials, comprising the following steps:

[0029] Step 1: Stator and rotor stamping dies are generally single-row or double-row, and the number of stamping rows for wave-shaped materials (based on 1200-1250MM large coil materials) is determined according to single-row or double-row;

[0030] Figure 8 and Figure 9 It is a schematic diagram and comparison between the layout of the stamped workpiece in the present invention and the traditional layout.

[0031] like Figure 8 The determined number of columns is 2, and the edge is 1.5MM, and the positions of the workpieces to be stamped are arranged in a cross, such as Figure 8 As shown, according to the 1210MM wide material design, the raw materials can be fully utilized.

[0032] Figure 8 Take the strip width of 1210mm as an example: in the case of the same strip width, Figure 8 The method of punching flower material can punch out 5 flower mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com