Anode for biological power generation and power generation method and device utilizing it

A bioelectric power generation and anode technology, applied to biochemical equipment and methods, microorganisms, microorganisms, etc., can solve the problems of inability to form series, no disclosure of methods and conditions, and reduced reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0177] [Example 1, Comparative Examples 1-2]

[0178] Example 1

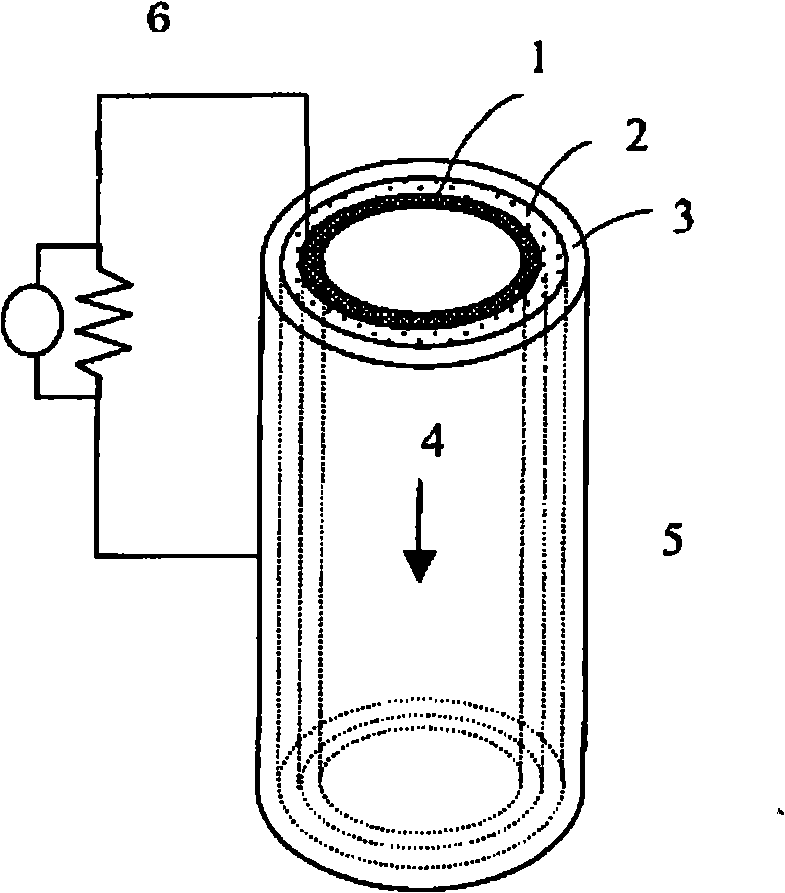

[0179] In Example 1, CARBOLON (registered trademark) Felt GF-20 manufactured by Carbon Japan was used as the carbon felt as the conductive substrate of the anode 1 . As the hydrophilic polymer, polyacrylic acid (molecular weight: about 1 million) manufactured by Wako Pure Chemical Industries was used. As the electron mediator, 1-aminoanthraquinone (AAQ) produced by Wako Pure Chemical Industries, Ltd. was used.

[0180] In Example 1, the anode (1) equipped in the biomass power generation device was produced by the following method. Prepare a polymer solution in which polyacrylic acid is dissolved at a concentration of 5 g / L relative to methanol, immerse graphite felt in it and shake for 30 seconds, take it out, shake off the excess polymer solution, and dry at 100°C for 24 hours to form an hydrophilic Waterborne polymer layer. The weight increase of the graphite felt caused by this operation was measured, and...

Embodiment 2~3、 comparative example 3

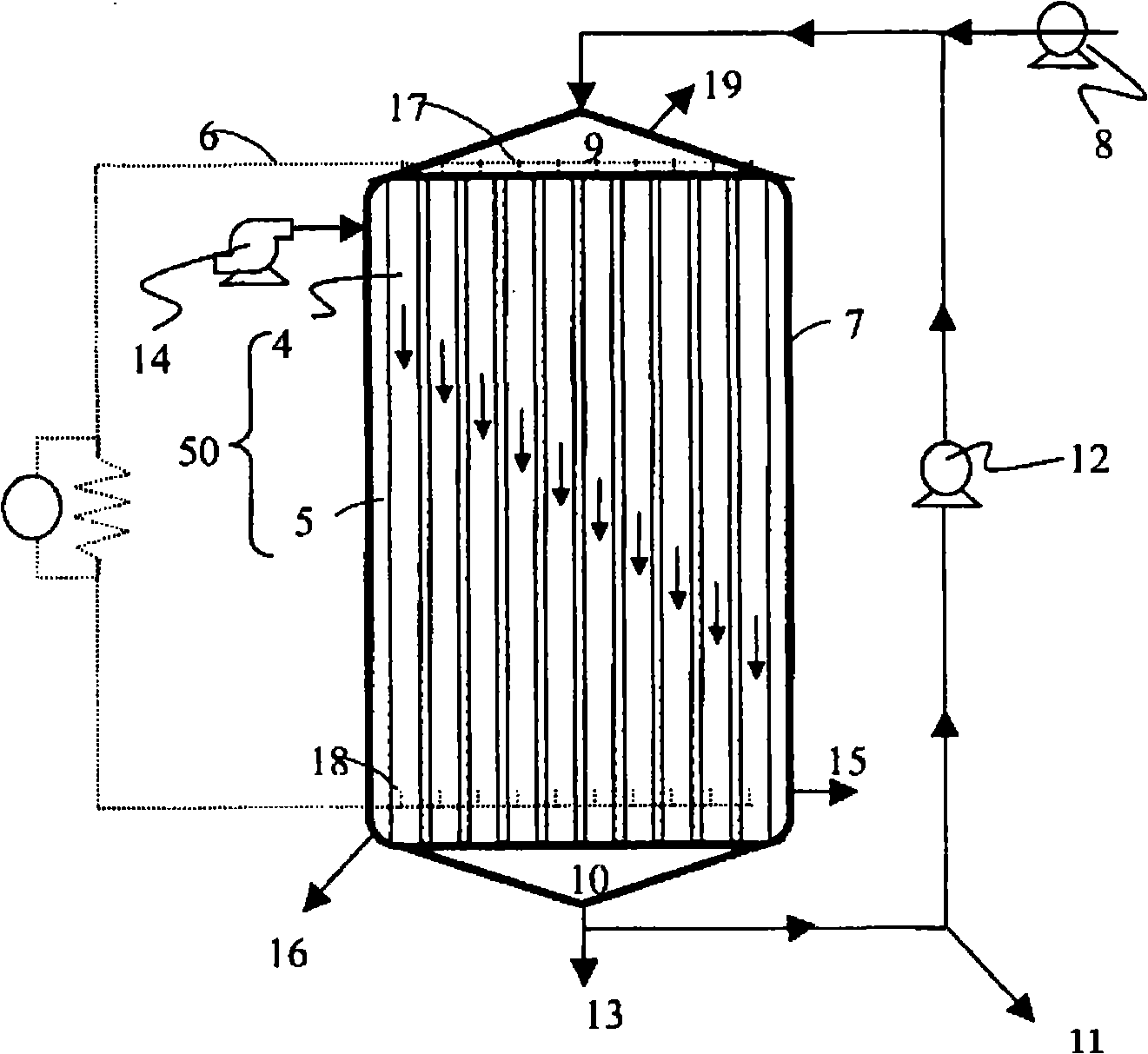

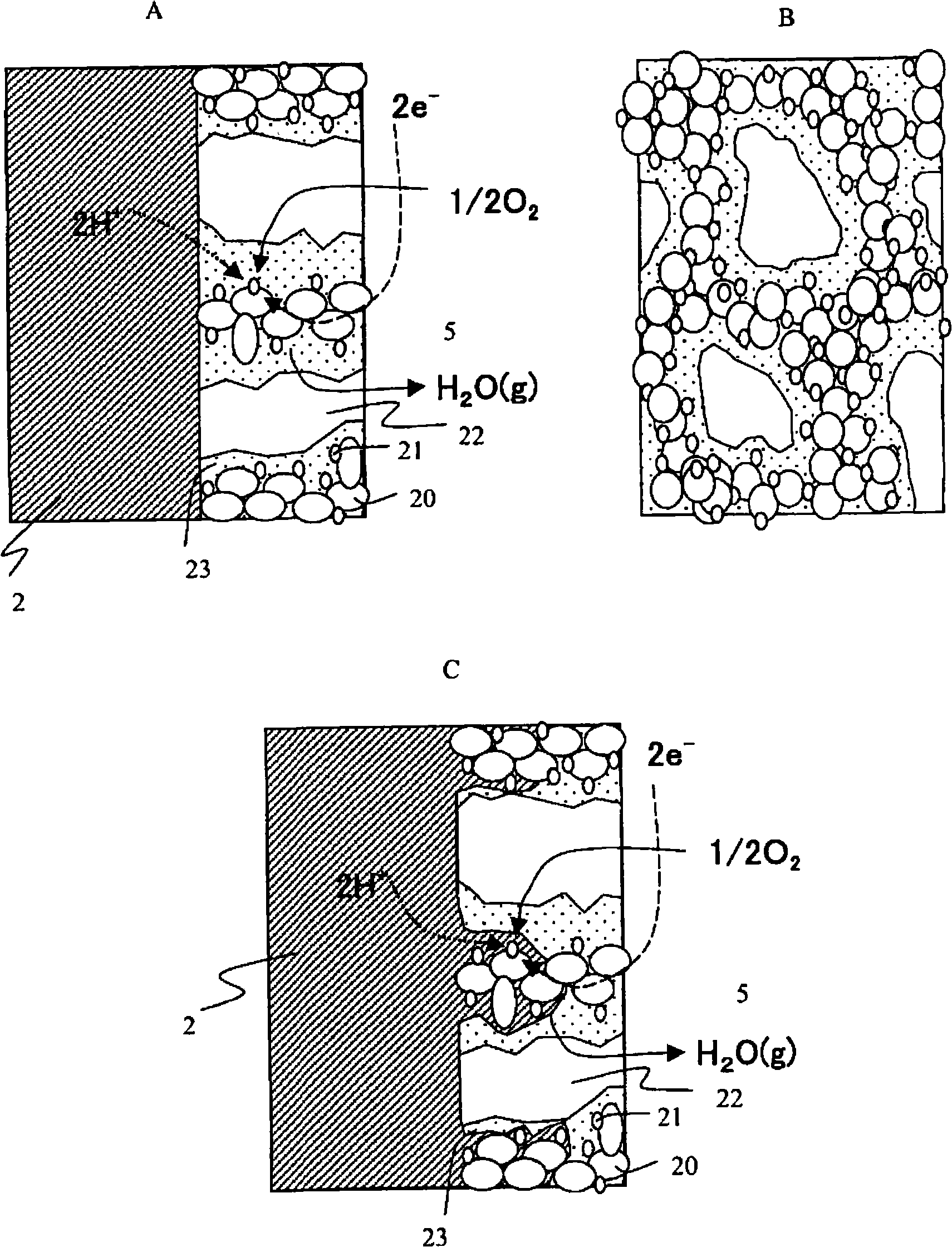

[0207] use Figure 4 The laboratory-use biopower generation device shown compares the power generation performance and the stability of the hydrophilic polymer layer-coated anode. In Examples 2 to 4 and Comparative Example 3, an aqueous solution of polyethyleneimine (EPOMIN (registered trademark) P-1000 produced by Japan Catalyst Co., Ltd.) with a molecular weight of 70,000 was impregnated in a conductive substrate (carbon felt) to form a hydrophilic A permanent polymer layer on which anthraquinone-2-sulfonic acid (AQS) is fixed and used as an anode. AQS uses the product previously sulfonyl chlorinated by the following method.

[0208] In an acetonitrile solvent containing 1 / 2 molar equivalent of sulfolane relative to 1 mole of AQS and 4 molar equivalents of phosphorus oxychloride, the reaction was carried out at 70° C. for 1 hour to sulfonylate the sulfonic acid group. After it was cooled, it was filtered, washed with ice water, and then dried to obtain a flesh-colored powd...

Embodiment 2

[0210]The anode (2) equipped in the biomass power generation device in Example 2 was produced by the following method. Dissolve polyethyleneimine in water to a concentration of 10 g / L to prepare a hydrophilic polymer solution, dip graphite felt as a conductive substrate in it, vibrate for 30 seconds, and shake off excess hydrophilicity after taking it out. The polymer solution was dried at 100°C for 24 hours to form a hydrophilic polymer layer. The weight increase of the graphite felt caused by this operation was measured, and the thickness of the hydrophilic polymer layer was calculated from the felt surface area measured by a specific surface area meter and the specific gravity of the fixed polymer 1.2, and was estimated to be 23 nm on average.

[0211] The thus-obtained hydrophilic polymer-coated felt (conductive substrate) was immersed in tetrahydrofuran, and the above-mentioned AQS chloride was added to the hydrophilic monomer unit constituting the hydrophilic polymer to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com