Stabilized flash calcined gibbsite as a catalyst support

A catalyst carrier, gibbsite technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., to achieve high sodium tolerance and excellent thermal stability , the effect of high pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

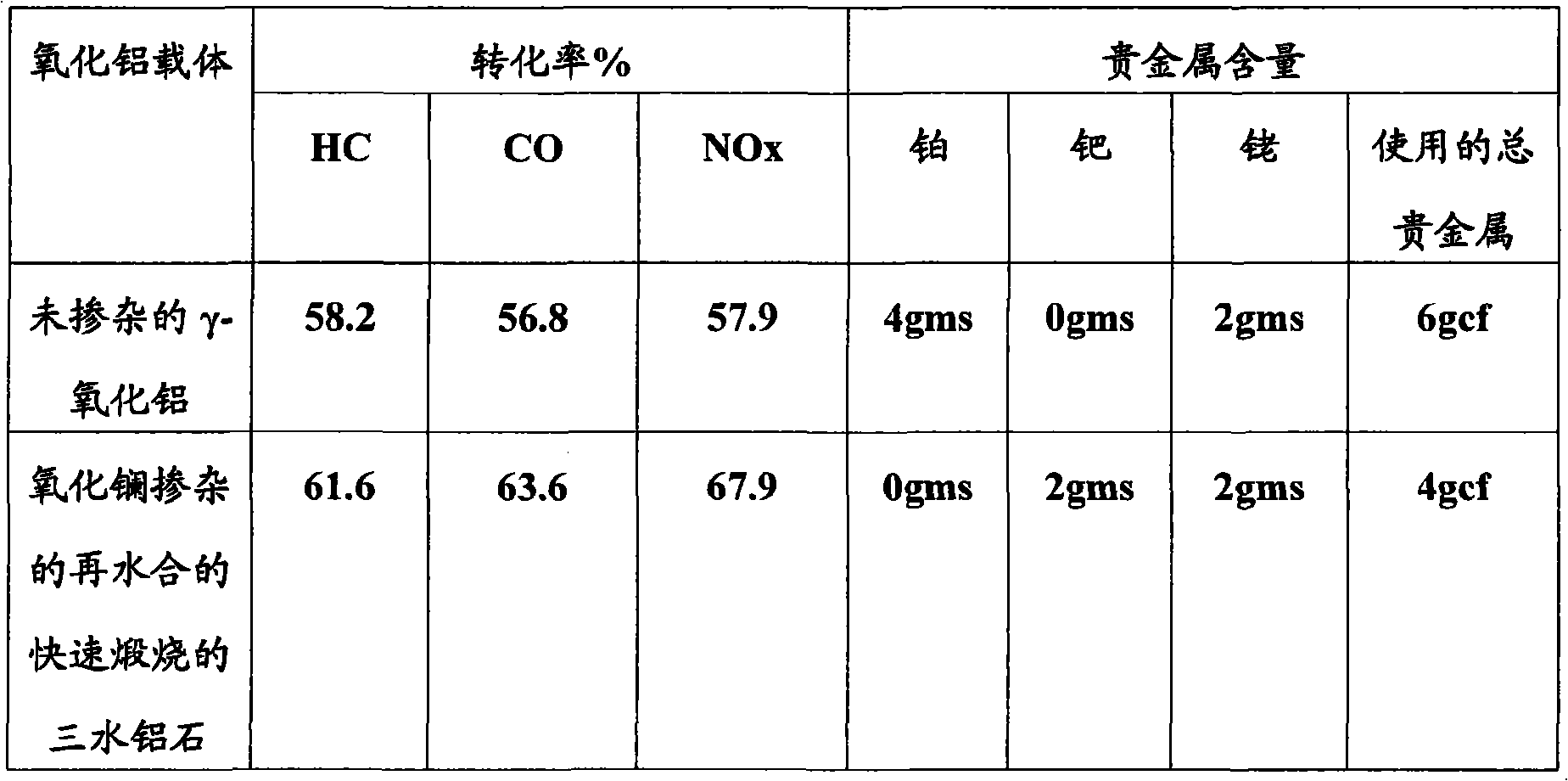

Examples

Embodiment 1

[0046] Preparation of rehydrated flash-calcined gibbsite:

[0047] 400 g of flash-calcined gibbsite (rho-alumina) (CP powder prepared by Almatis AC, Inc. of Vidalia, LA, with 268m 2 / g BET surface area and Na 2 (2 impurity 2500ppm) was added into 1600g of deionized (DI) water while stirring. 11.9 g of formic acid (98%, from VWR) was slowly added to the slurry with vigorous stirring. The acidified slurry was heated to 95°C and maintained at this temperature for 2 hours with stirring. After 2 hours, the slurry was filtered and washed three times with hot DI-water, and the solid was dried overnight at 105°C. The rehydrated flash-calcined gibbsite has 350-420m 2 / g surface area and Na 2 50-500ppm Na impurity represented by O.

Embodiment 2

[0049] Lanthanum oxide-doped rehydrated flash-calcined gibbsite (3% La) was prepared by incipient wetness impregnation:

[0050] 47.6g La(NO 3 ) 3 ·6H 2 O (from Alfa Aesar) was dissolved in 300 g DI-water. 550 g of the rehydrated flash-calcined gibbsite as formed in Example 1 were then impregnated with the above solution. The solid was dried and calcined in air at 815°C (1500°F) for 2 hours. The resulting lanthanum oxide-doped rehydrated flash-calcined gibbsite has about 120-150m 2 / g surface area.

Embodiment 3

[0052] Lanthanum oxide-doped rehydrated flash-calcined gibbsite (3% La) was prepared by spray drying:

[0053] From 3.5 lbs of rehydrated flash-calcined gibbsite as formed in Example 1, 4.9 lbs of DI-water, and 119 g La(NO 3 ) 3 ·6H 2 O (from Alfa Aesar) was made into a slurry. The slurry was spray dried and the microspheres were calcined in air at 815°C (1500°F) for 2 hours. The resulting lanthanum oxide-doped rehydrated flash-calcined gibbsite has 120-150m 2 / g surface area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com