Combined rectification column for preparing biological diesel oil

A technology of biodiesel and rectification tower, which is applied in the field of biodiesel preparation equipment, can solve the problems of difficult industrialization, intermittent production cannot complete reaction and separation in one device at the same time, and harsh reaction conditions, so as to achieve no pollution of three wastes , a wide range of applications, the effect of sufficient response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

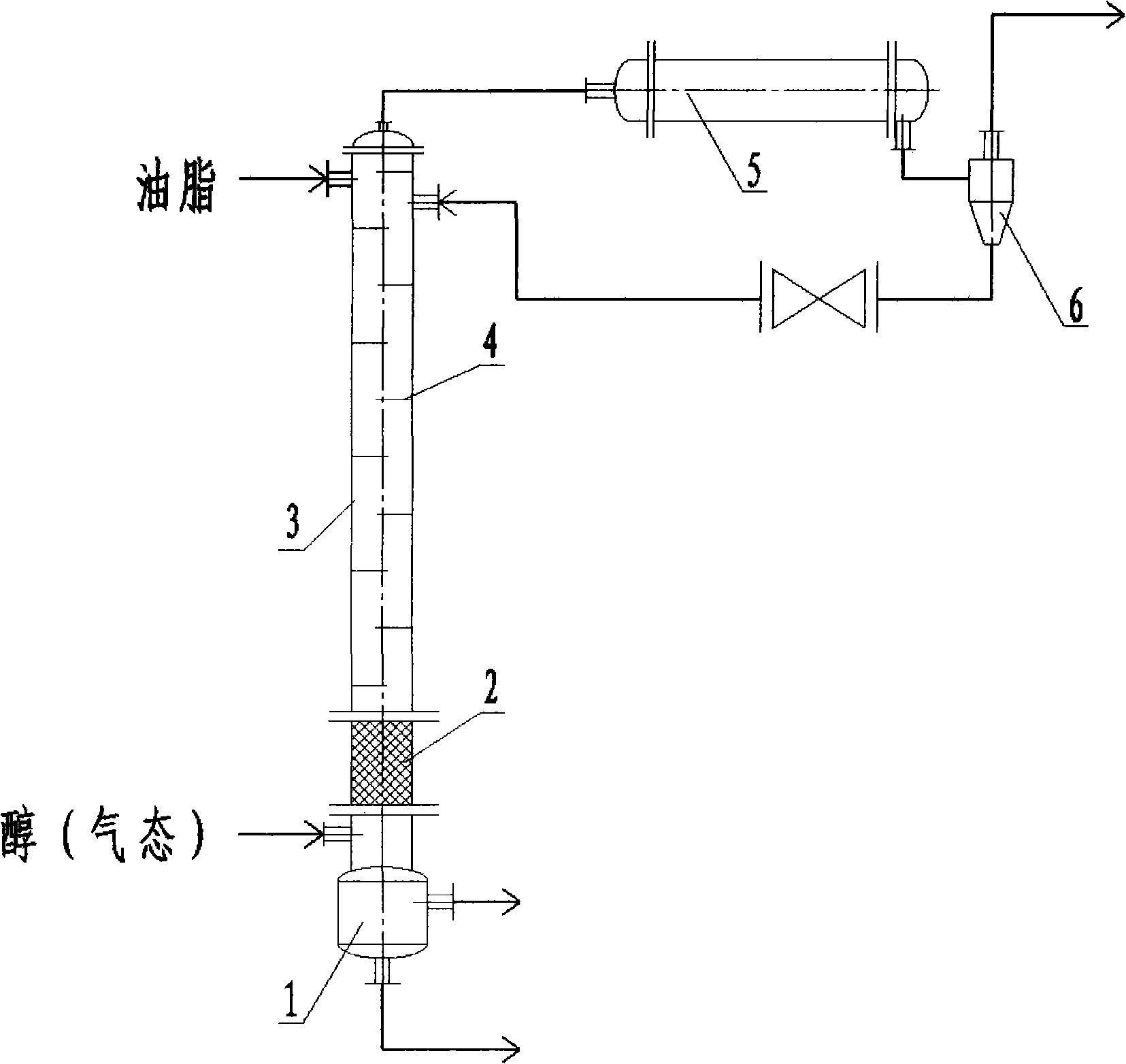

[0021] Use as attached figure 1 The structure parameters of the composite rectification tower device shown are: rectification tower diameter 1000mm, tray spacing 300mm, hole diameter 4mm, plate thickness 2mm, weir length 650mm, weir height 50mm, downcomer cross-sectional area / tower cross-section The area is 0.068, the hole area / tray working area is 0.09, the distance between the lower edge of the downcomer and the tray surface is 30mm, the diameter of the filler ceramic Raschig ring is 25mm, the wall thickness of the filler is 2.5mm, and a magnetic sulfonated coal solid catalyst is installed inside. Closed with wire mesh, the height of the packing layer is 3m. The acidified oil with an acid value of 100 enters from the top of the rectification tower with a flow rate of 0.0017m 3 / s, gaseous methanol enters continuously from the bottom of the tower with a flow rate of 0.77m 3 / s, reverse feeding, the temperature of the tower kettle is 120°C. Wire mesh is installed on the tra...

Embodiment 2

[0023] The composite rectification tower as shown in the attached figure is adopted, the garbage oil with an acid value of 20 enters from the top of the rectification tower, and the gaseous ethanol enters continuously from the bottom of the tower, reverse feeding, and the temperature of the bottom of the tower is 130°C. Wherein the rectifying column packing is Raschig ring, and both the tray plate and the packing are loaded with zirconium solid superacid catalyst. The tray spacing is 400mm, the outlet weir height is 120mm, and the number of trays is 100. The unreacted ethanol is condensed by the overhead condenser and then returned to the rectification column for circulation. The generated biodiesel, glycerin and water flow out through the bottom of the tower.

Embodiment 3

[0025] The composite rectification tower as shown in the attached figure is adopted, rapeseed oil is used as the raw material to enter from the top of the rectification tower, gaseous isopropanol is continuously fed from the bottom of the tower, reverse feeding, and the temperature of the bottom of the tower is 110°C. Among them, the rectification column packing is Raschig ring, and the column plate is loaded with γ-Al 2 o 3 NaOH solid basic catalyst. The tray spacing is 400mm, the outlet weir height is 200mm, and the number of trays is 50. The unreacted ethanol is condensed by the overhead condenser and then returned to the rectification column for circulation. The generated biodiesel and glycerol flow out through the tower kettle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com