Cantilever member, magnetic head folding piece combination and manufacturing method and disk driving unit

A cantilever and magnetic head technology, applied in the installation of arm parts, the structure of arm parts, the support head, etc., can solve the problems of poor anti-vibration performance, difficult control, unstable combination performance of magnetic head flaps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

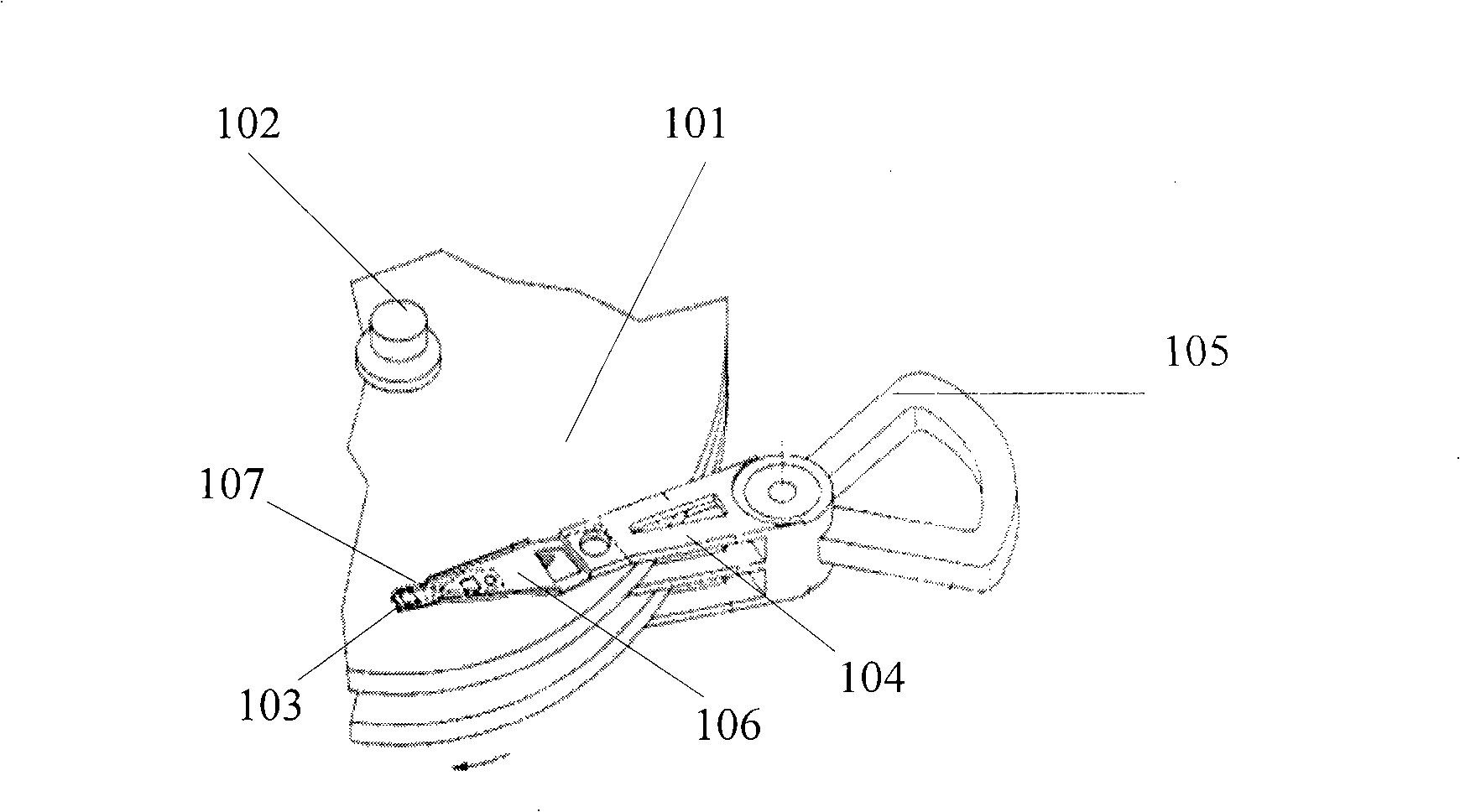

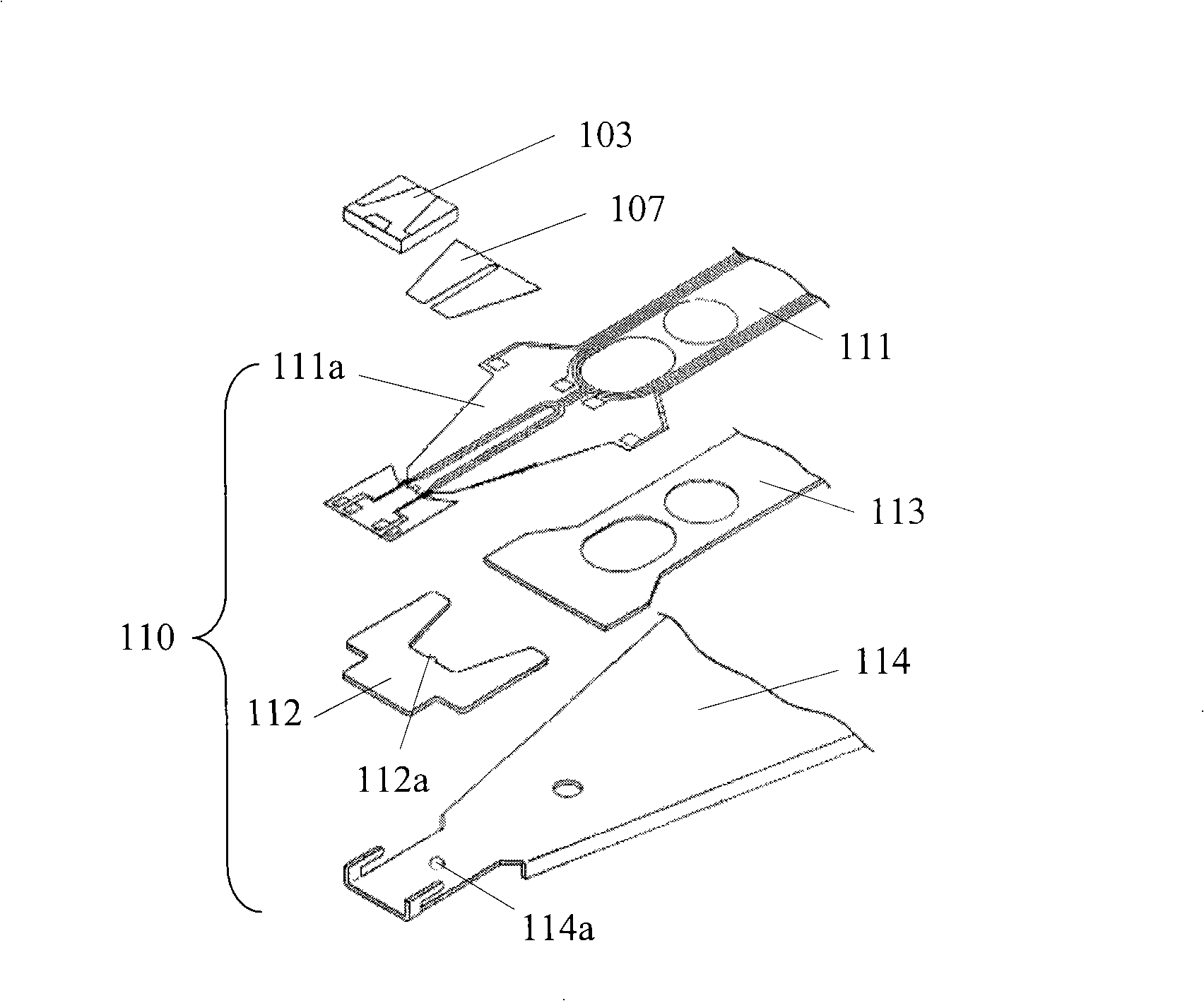

[0041] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the present invention aims to provide a suspension for suspending a magnetic head for recording or reproducing information relative to an information medium. The cantilever member includes a flexible member having a tongue region and an outer trigger plate. The outer trigger plate has a pair of rigid arms and a pair of elastic arms. The pair of rigid arms are respectively connected to opposite sides of the tongue region of the flexible member. Each of the pair of elastic arms has one end connected to the free end of its corresponding rigid arm, and the other end extends to the middle area of the magnetic head mounting portion of the flexible member for carrying the magnetic head. The structure of the outer trigger plate of the cantilever part makes the flexible part have a good elastic rate in the X-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com