Density calibration method of carbon/silicon carbide ceramic matrix composite

A technology of silicon carbide ceramic matrix and composite materials, applied in the direction of analyzing materials, using radiation for material analysis, measuring devices, etc., can solve the problems of low measurement accuracy, achieve the effects of improving calibration accuracy, reducing the number of CT scans, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: refer to Figure 1~4 . The 1K carbon fiber is woven into a nozzle fiber preform using a three-dimensional four-step method, and a pyrolytic carbon interface layer is deposited on the nozzle fiber preform. The process conditions are: deposition temperature 800°C, pressure 0.2kPa, propylene flow rate 35ml / min, Ar The gas flow rate is 250ml / min, and the deposition time is 60h.

[0021] The silicon carbide substrate was deposited on the carbon fiber nozzle deposited with the pyrolytic carbon interface layer. The process conditions were: deposition temperature 800 ° C, pressure 4 kPa, H 2 Gas flow 150ml / min, Ar gas flow 250ml / min, trichloromethylsilane temperature 35°C, H 2 The molar mass ratio to MTS is 1:12, and the total deposition time is 240h.

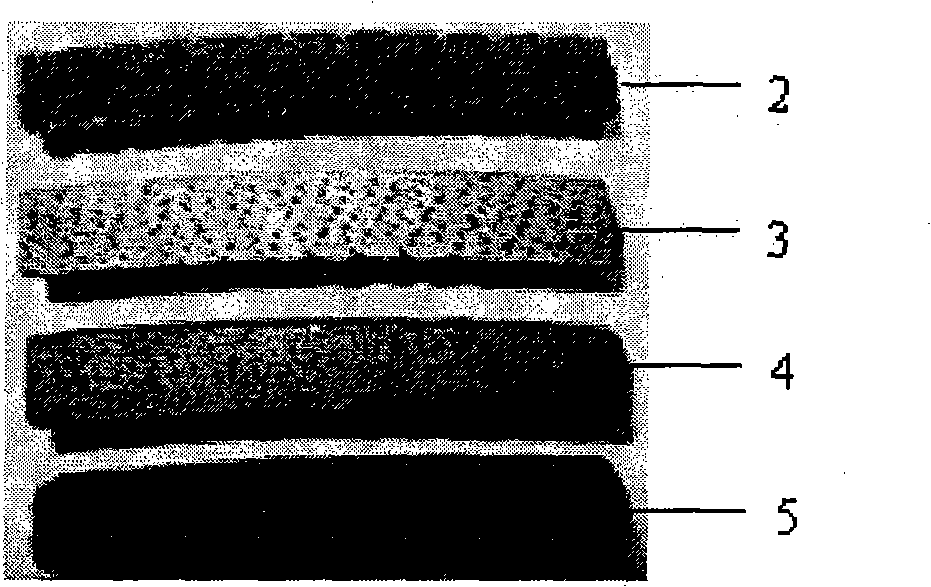

[0022] At each dense stage of depositing the SiC matrix, a 4×25mm furnace sample was taken from the edge of the blank of the nozzle 1 as a gradient density standard sample. When the SiC matrix was deposited for...

Embodiment 2

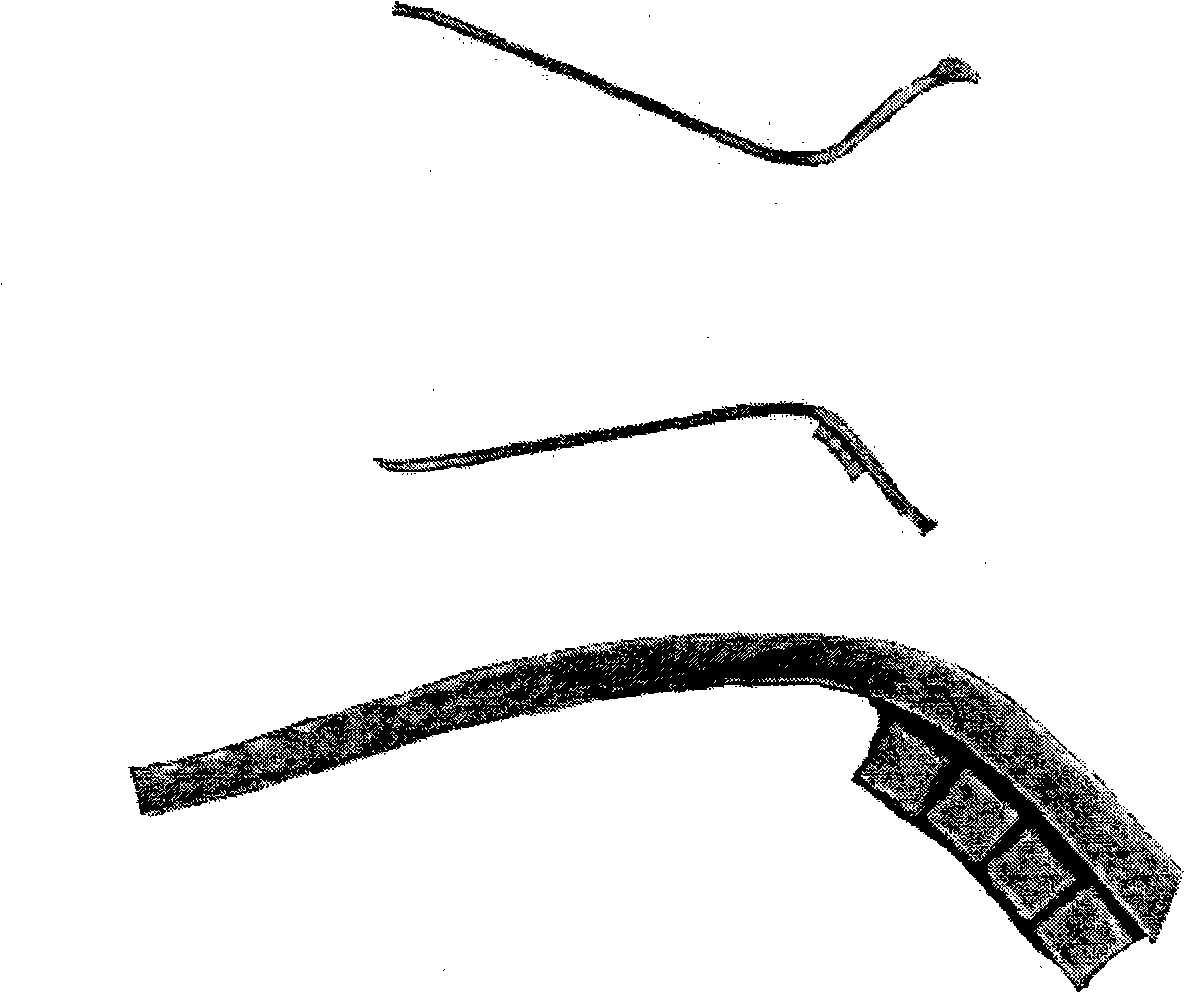

[0028] Embodiment 2: refer to figure 1 , 5 And 6, the single-layer carbon fiber 0° non-weft cloth, tire mesh, 90° non-weft cloth, and tire mesh are stacked in sequence from the inside to the outside with several layers, and the density is 0.3 ~ 0.6g / cm3 prepared by the relay acupuncture method 3 Three-dimensional acupuncture nozzle prefabricated body, pyrolytic carbon interface layer deposited on the nozzle prefabricated body, the process conditions are: deposition temperature 800 ℃, pressure 0.2kPa, propylene flow rate 35ml / min, Ar gas flow rate 250ml / min, deposition time 60h .

[0029] The silicon carbide substrate was deposited on the three-dimensional needle-punched nozzle preform deposited with the pyrolytic carbon interface layer. The process conditions were: deposition temperature 800 ° C, pressure 4 kPa, H 2 Gas flow 150ml / min, Ar gas flow 250ml / min, trichloromethylsilane temperature 35°C, H 2 The molar mass ratio to MTS is 12, and the deposition time is 240h.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com