Method for extracting thallium from thallium containing slag

A technology for extracting metal and thallium slag, which is applied in the direction of improving process efficiency, can solve the problems of high price and thallium pollution of the electrolytic thallium extraction method, and achieves the effects of flexible extraction purity grade, low energy consumption and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

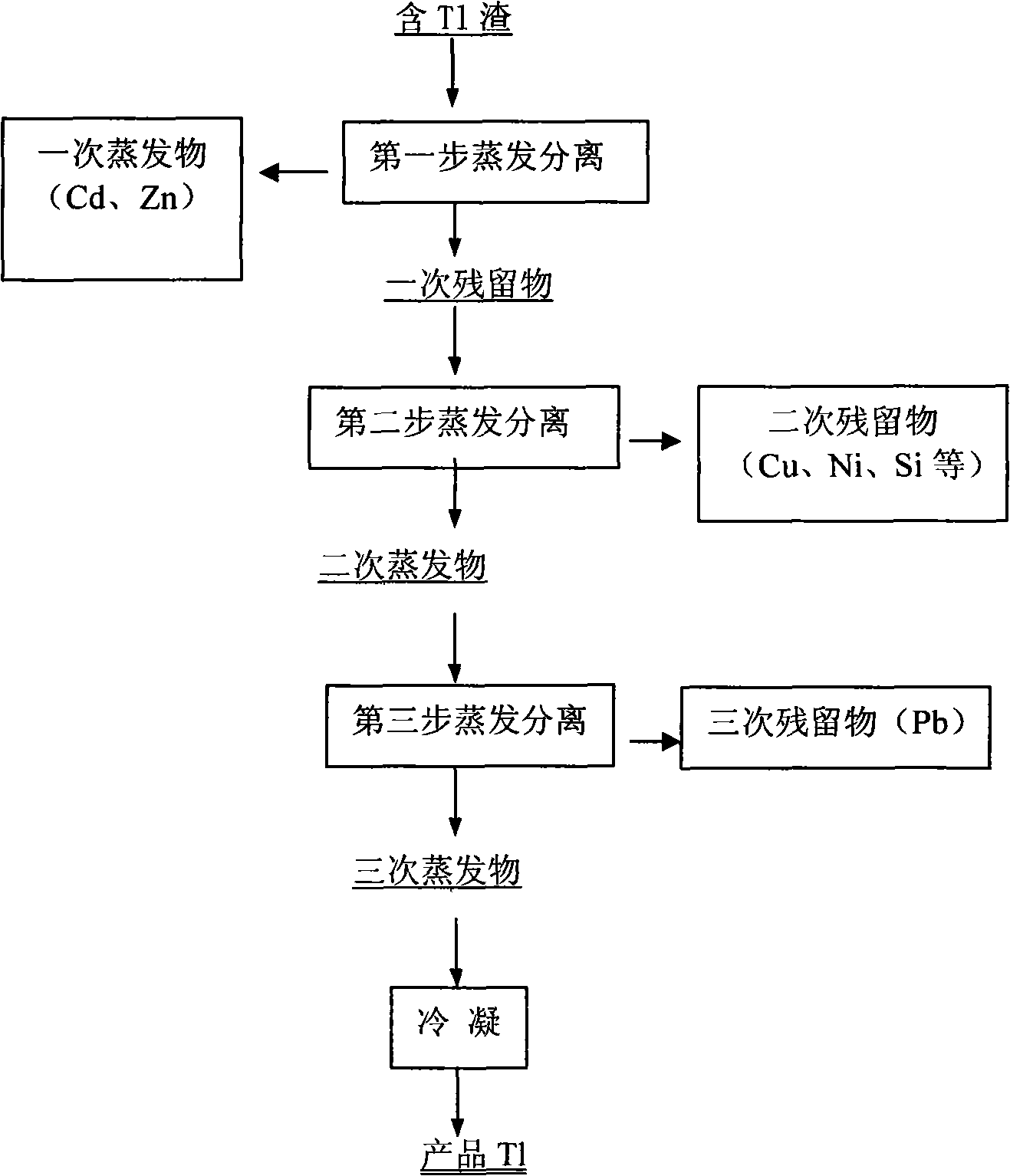

[0013] Example 1: Using thallium-containing slag as raw material, its main components are Cd 60.8%, Cu 2.10%, Ni 3.02%, Pb 1.64%, Zn 0.0056%, Si 0.50%, Tl 24.68%, and vacuum primary separation , Control temperature 500-550℃, heating time 30min, of which heat preservation at 550℃ for 20min, vacuum 8-20Pa. Obtaining a primary evaporate containing Cd and Zn and a primary residue containing Tl, the purpose is to achieve as much Tl as possible enrichment in the primary residue while removing Cd and Zn;

[0014] Use the primary residue as the raw material to perform vacuum secondary separation, control the temperature at 900-1000°C, and the heating time for 35min, of which the temperature is kept at 1000°C for 20min, and the vacuum degree is kept at 8-20Pa. Obtain the secondary evaporate containing Tl and the secondary residue containing Fe, Cu, Ni, Si, the purpose is to achieve the removal of Fe, Cu, Ni, Si and other elements at the same time, as much as possible enrichment of Tl in th...

Embodiment 2

[0016] Example 2: The weight percentages of the main components of the raw material containing thallium slag are Cd 59.2%, Cu 2.50%, Ni 2.82%, Pb 1.24%, Zn 0.015%, Si 0.60%, Tl 20.68%, vacuum primary separation, control temperature 550- 600°C, heating time 30min, of which heat preservation at 580°C for 20min, vacuum 8-40Pa. Obtaining a primary evaporate containing Cd and Zn and a primary residue containing Tl, the purpose is to achieve as much Tl as possible enrichment in the primary residue while removing Cd and Zn;

[0017] The primary residue is used as the raw material, and the vacuum secondary separation is carried out, the temperature is controlled at 1050-1100°C, the heating time is 35min, and the temperature is kept at 1100°C for 20min, and the vacuum degree is maintained at 8-40Pa. Obtain the secondary evaporate containing Tl and the secondary residue containing Fe, Cu, Ni, Si, the purpose is to achieve the removal of Fe, Cu, Ni, Si and other elements at the same time, as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com