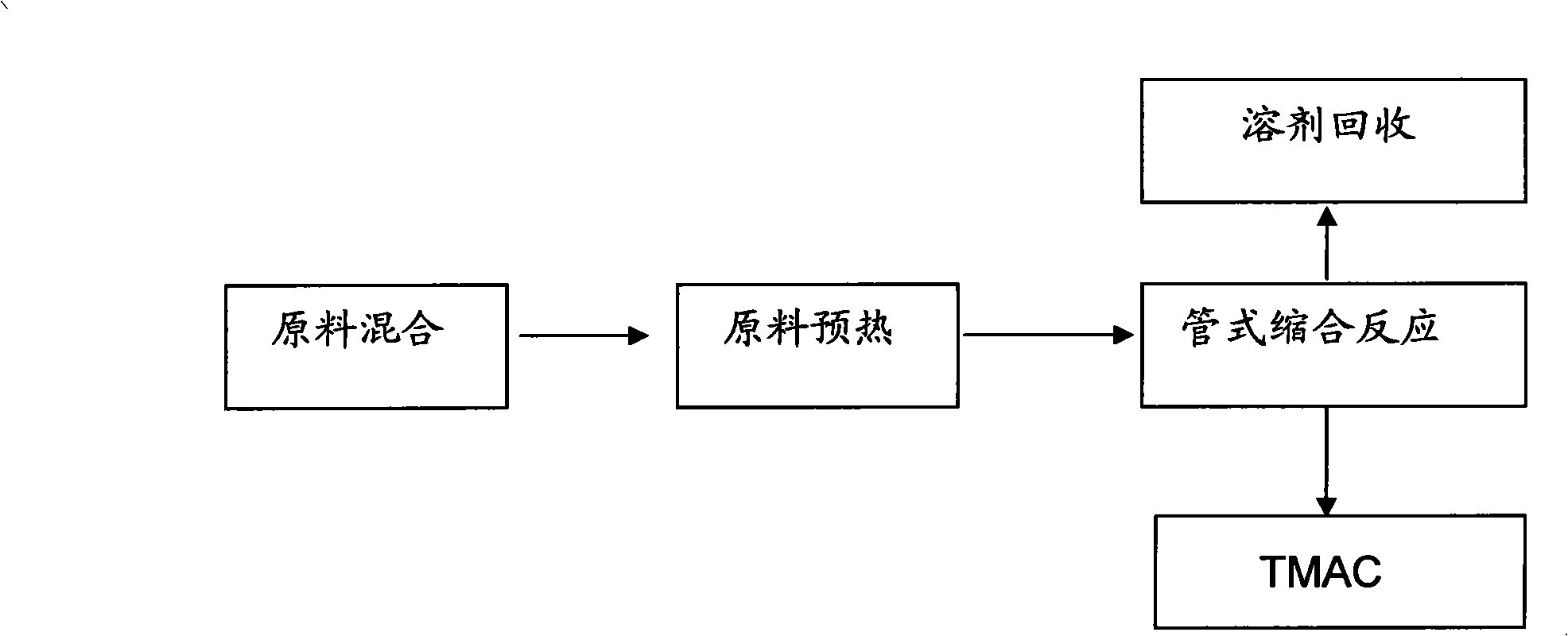

Method for preparing tetramethyl ammonium hydrogen carbonate with condensation reaction of pipe type reactor

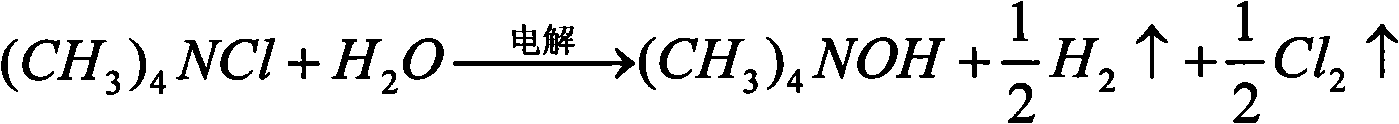

A tetramethylammonium bicarbonate, tubular reactor technology, which is applied in the preparation of amino compounds by condensation/addition reactions, the preparation of amino compounds, chemical instruments and methods, etc. Stability and other issues, to achieve the effect of stable product quality, simple equipment and high use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

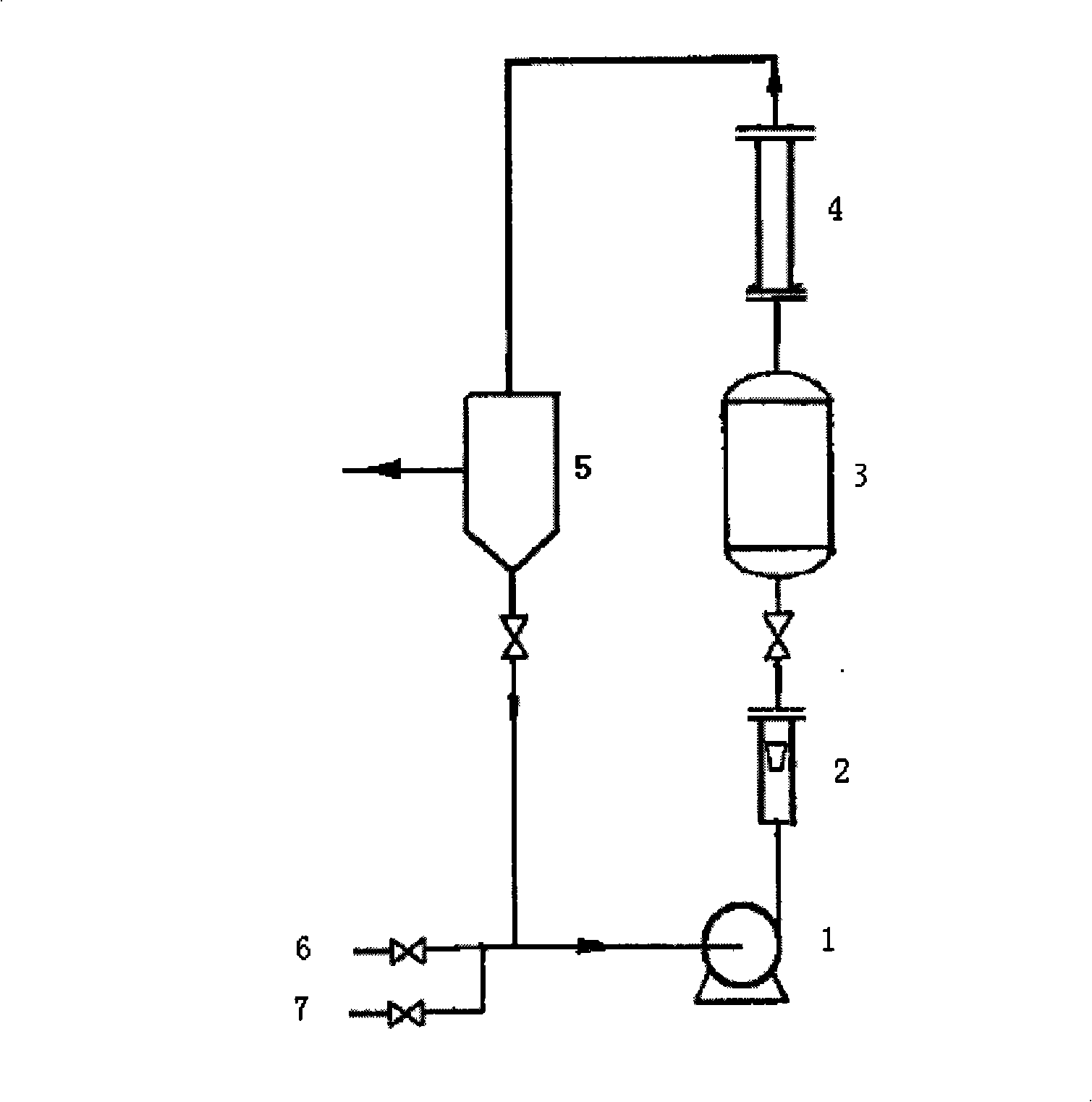

Method used

Image

Examples

Embodiment 1

[0028] The tubular reactor is equipped with a static mixer, with 1000ml of methanol as the solvent, the raw material ratio (molar ratio) DMC:TMA=0.95:1, the reaction temperature is 115°C, and the reaction pressure is 0.5MPa. The continuous reaction time is 130 Minutes, a sample was taken and chromatographically analyzed for the content of dimethyl carbonate, and the conversion rate was 93.4%.

Embodiment 2

[0030] With 1000ml ethanol as solvent, in raw material proportioning (molar ratio) DMC: TMA=1: 1, reaction temperature is 115 ℃, reaction time is 130 minutes under the condition of reaction pressure 0.5MPa, sampling and chromatographic analysis dimethyl carbonate content, the conversion rate is 90.1%.

Embodiment 3

[0032] With 1000ml of acetone as solvent, in raw material proportioning (molar ratio) DMC: TMA=1: 1, reaction temperature is 105 ℃, reaction time is 175 minutes under the condition of reaction pressure 0.8MPa, sampling and chromatographic analysis dimethyl carbonate content, the conversion rate is 88.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com