High-strength high-ductility fluorine alkalescent sintered flux

A technology of sintering flux and high toughness, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc. It can solve the problems that cannot meet the requirements of high strength and high toughness, so as to improve the performance of welding process, high and low temperature impact toughness, and guarantee The effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

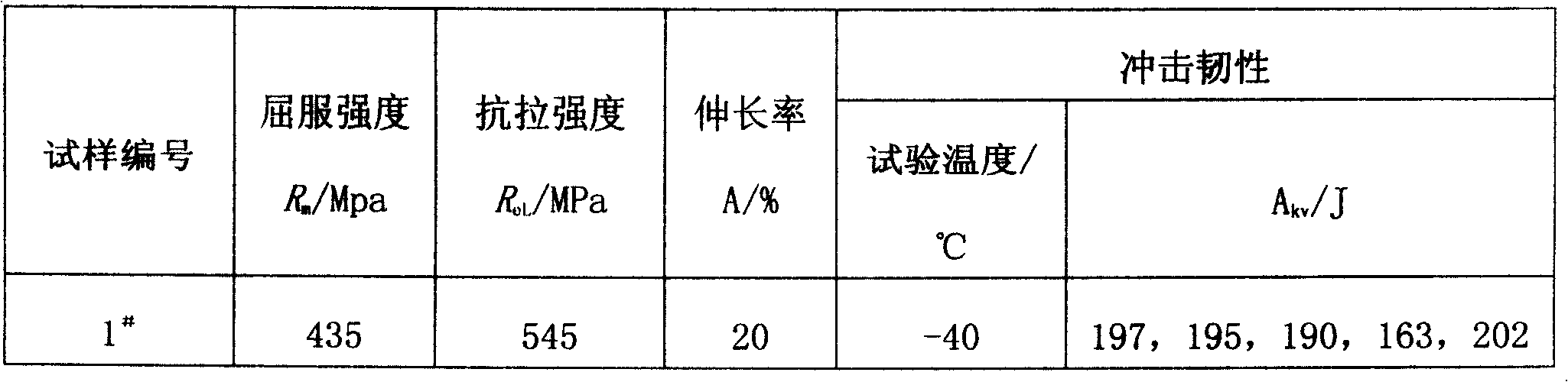

[0016] Embodiment 1 (flux batch number: 001):

[0017] (1) Flux composition (Wt%): MgO 24.8, CaF 2 25.8, Al 2 o 3 22.2, SiO 2 15.3, CaO5.3, MnO3.8, FeO2.3, Na 2 O 0.462, S 0.009, P 0.029.

[0018] (2) Alkalinity of flux (B IIW ): 2.25

[0019] (3) Preparation method: After the required raw materials are re-inspected, the processes of coarse crushing, fine crushing, and powder grinding are carried out, and processed into powders with different standard particle sizes. After sieving, carry out proportioning and weighing according to the formula, then put it into a dry blender for dry blending, put the evenly stirred powder into a wet blender, add about 20% of water glass for wet blending, stir well, stir well The wet material is sent to the granulator for granulation, and the granulated flux produced is sent to the drying furnace after being dried by hot air, and is dried at a temperature of 150°C to 200°C to remove moisture and then sieve and sieve. The flux within t...

Embodiment 2

[0022] Embodiment 2 (flux batch number: 002):

[0023] (1) Flux composition (Wt%): MgO 24.6, CaF 2 26.1, Al 2 o 3 22.7, SiO 2 15.1, CaO5.6, MnO3.4, FeO2.1, Na 2 O 0.367, S 0.007, P 0.026.

[0024] (2) Alkalinity of flux (B IIW ): 2.25

[0025] (3) Preparation method: same as Example 1.

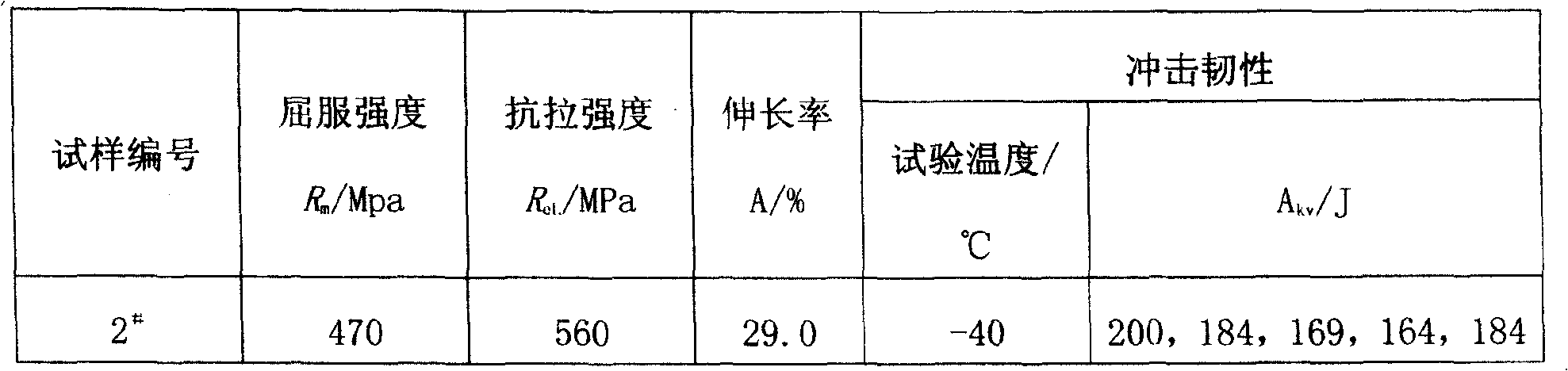

[0026] (4) Test results of mechanical properties of deposited metal (with YS-H08D welding wire):

[0027]

Embodiment 3

[0028] Example three (flux batch number: 003)

[0029] (1) Flux composition (Wt%): MgO 25.2, CaF 2 25.2, Al 2 o 3 22.5, SiO 2 15.2, CaO5.6, MnO3.6, FeO2.3, Na 2 O 0.362, S 0.009, P 0.029.

[0030] (2) Alkalinity of flux (B IIW ): 2.24

[0031] (3) Preparation method: same as Example 1.

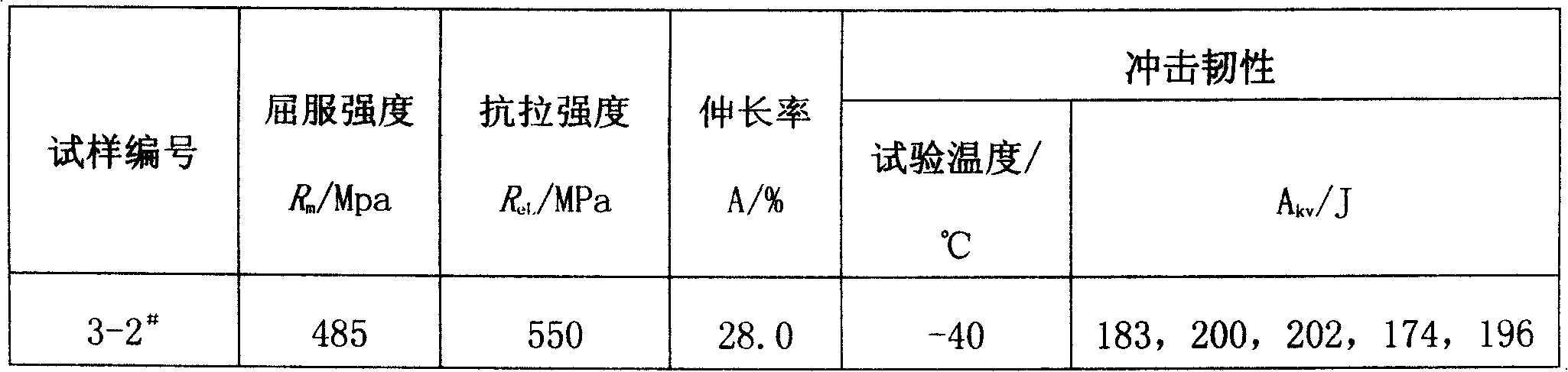

[0032] (4) Test results of mechanical properties of deposited metal (with YS-H08D welding wire):

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com