Drying separator

A separation device and drying technology, applied in separation methods, drying solid materials, separation of dispersed particles, etc., can solve the problems of high pin wheel speed, easy sticking to walls, failure to separate absorbent mist beads and absorption products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

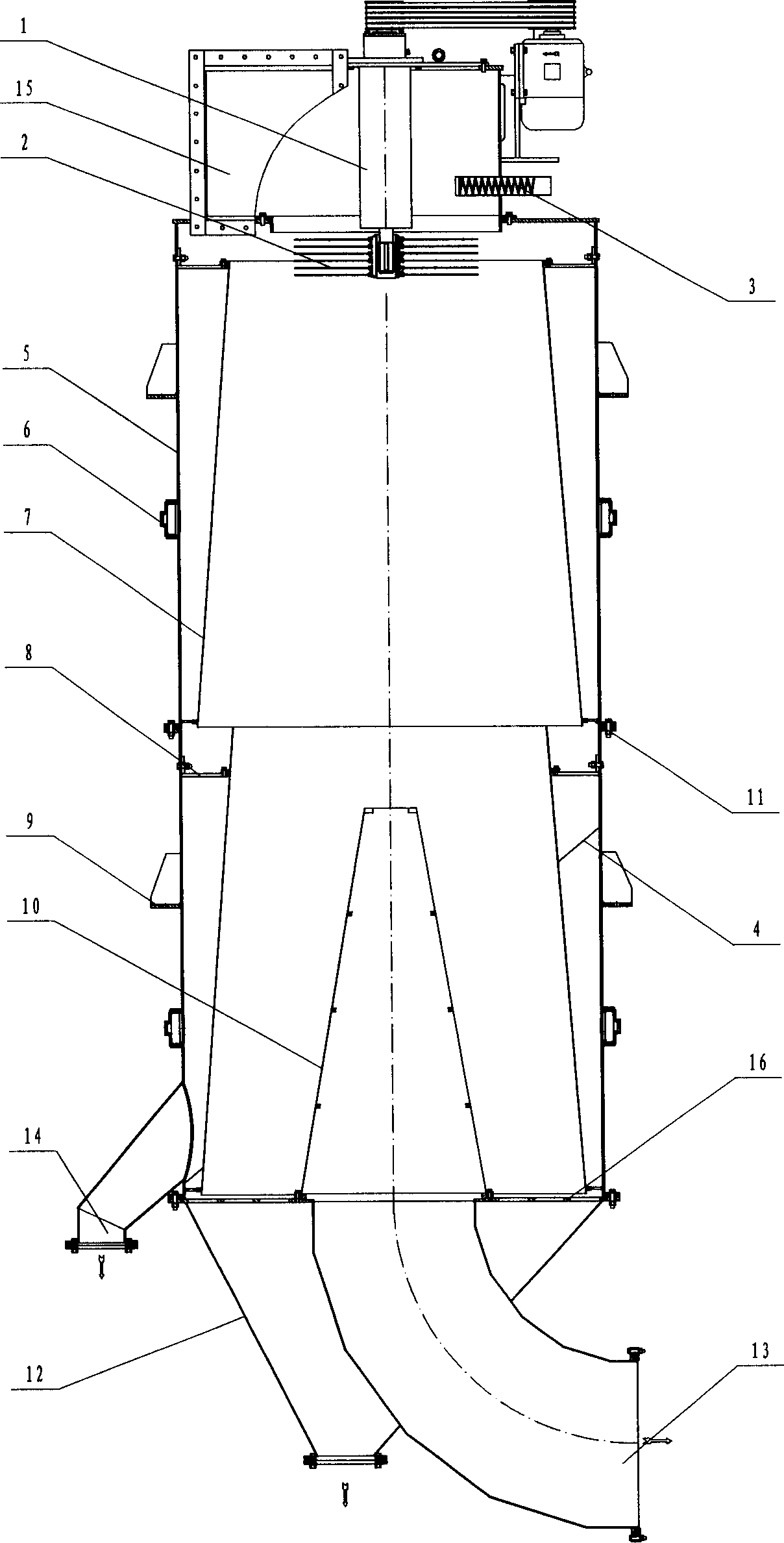

[0121] see figure 1 , the present embodiment is a kind of upper air spin-rotating dispersed drying and separation device designed according to the technical solution 1 of the present invention, which is used for catalysts, detergents, dyes, pigments, fertilizers, polymers, ceramic raw materials, minerals, pesticides, pharmaceuticals , Drying of instant food, especially the dispersion and drying of pasty materials.

[0122] It includes a tower body, a set of transmission device 1, a set of unrotating pin wheel 2, an air inlet part, an air outlet part, a feeding device 3, a blanking part, a classifier 7, and an aerodynamic separator 10.

[0123] The tower body is upright, the air inlet part is on the top, the blanking part and the air outlet part are on the bottom.

[0124] The air intake part is composed of an inlet flange, a coaming plate, an end volute ring flange, a lower volute ring flange, and a lower cylinder section. Eccentric tangential intake. The inner circles of ...

Embodiment 2

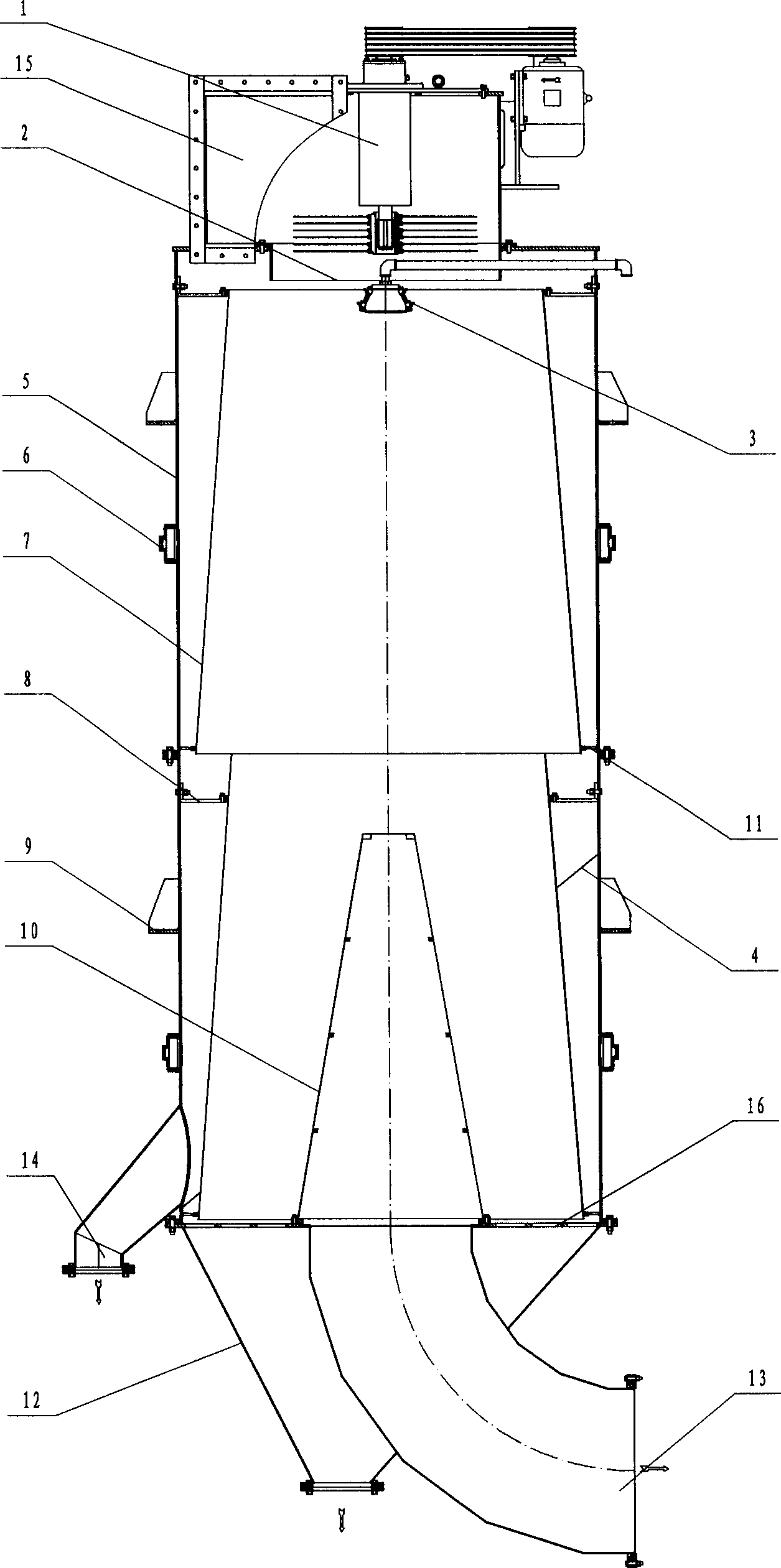

[0135] see figure 2 , this embodiment is an upper air-intake swirling spray drying and separation device designed according to the first technical solution of the present invention. It is used for drying of catalysts, detergents, dyes, pigments, fertilizers, polymers, ceramic raw materials, minerals, pesticides, medicines, instant foods, for cooling drying, granulation, for evaporation and concentration, and for gas absorption.

[0136] It includes a tower body, a set of transmission device 1, a set of unrotating pin wheel 2, an air inlet part, an air outlet part, a feeding device 3, a blanking part, a classifier 7, and an aerodynamic separator 10.

[0137] Its components and features are exactly the same as those in Embodiment 1, except that the feeding device 3 contains a spray head, and there are two layers of atomizing nozzles arranged around the spray head. The feeding device 3 is fixed on the tower body. Unrotate pin wheel 2 retracts in the air intake part.

Embodiment 3

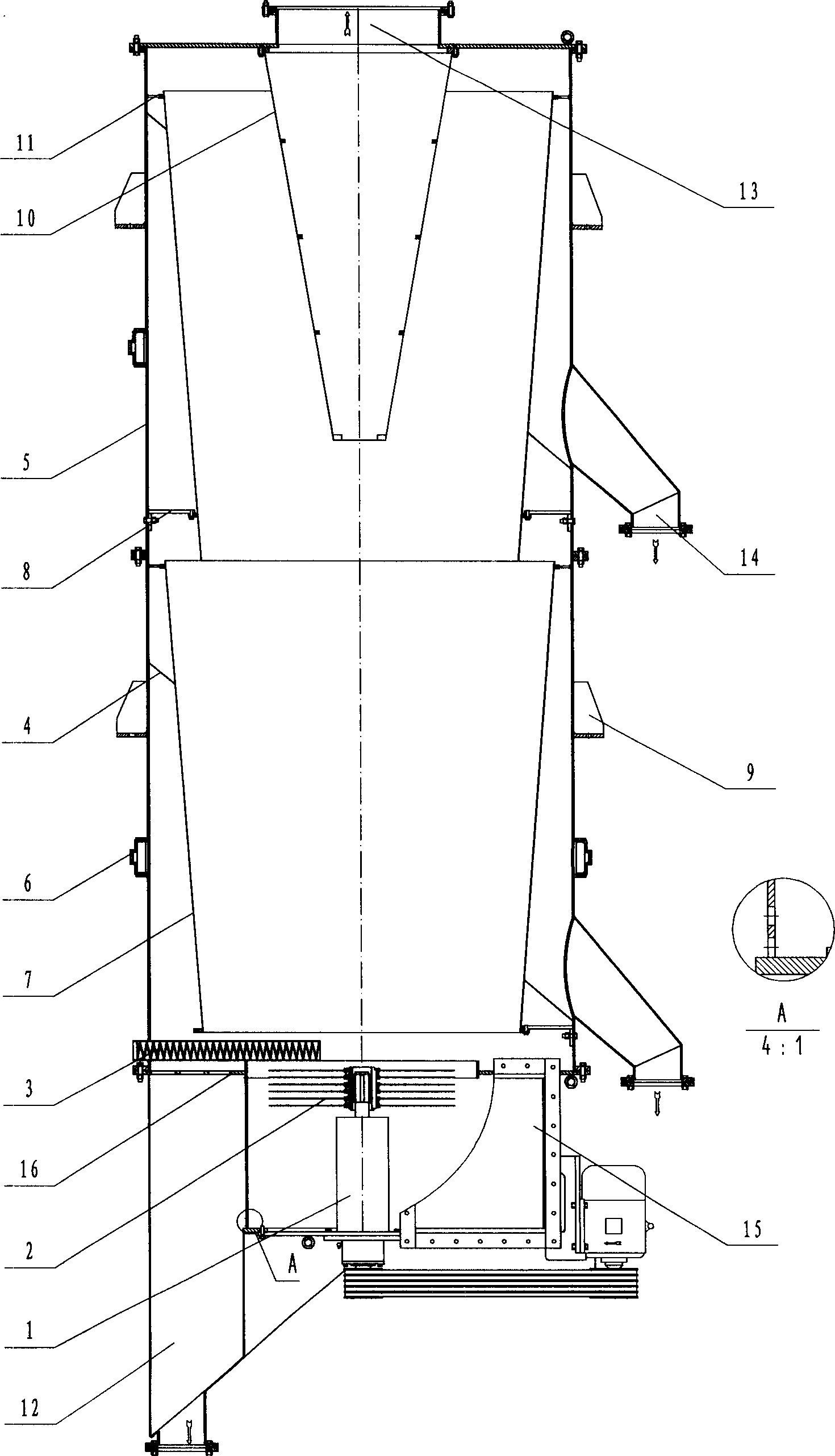

[0139] see image 3 , the present embodiment is a kind of down-inlet swirling dispersive drying and separation device designed according to the technical solution 1 of the present invention. It is used for the drying of catalysts, detergents, dyes, pigments, fertilizers, polymers, ceramic raw materials, minerals, pesticides, medicines, instant foods, especially the dispersion and drying of pasty materials.

[0140] It includes a tower body, a set of transmission device 1, a set of unrotating pin wheel 2, an air inlet part, an air outlet part, a feeding device 3, a blanking part, a classifier 7, and an aerodynamic separator 10.

[0141] The characteristics of its tower body, air intake components, transmission device 1, unrotating pin wheel 2, feeding device 3, classifier 7, and aerodynamic separator 10 are the same as those in the first embodiment.

[0142] It differs from Embodiment 1 in that: the tower body contains two drop pipe heads 14 , and correspondingly, there are t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com