Low-temperature molten salt thermal inversion preparation method of aporate-crystal antifungin whiskers

A technology of magnesium borate whiskers and low-temperature molten salt, applied in the directions of borates, chemical instruments and methods, boron oxide compounds, etc., can solve the problems of uneven morphology, product agglomeration, and high temperature, and achieve uniform morphology and dispersion. Good, good crystallizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

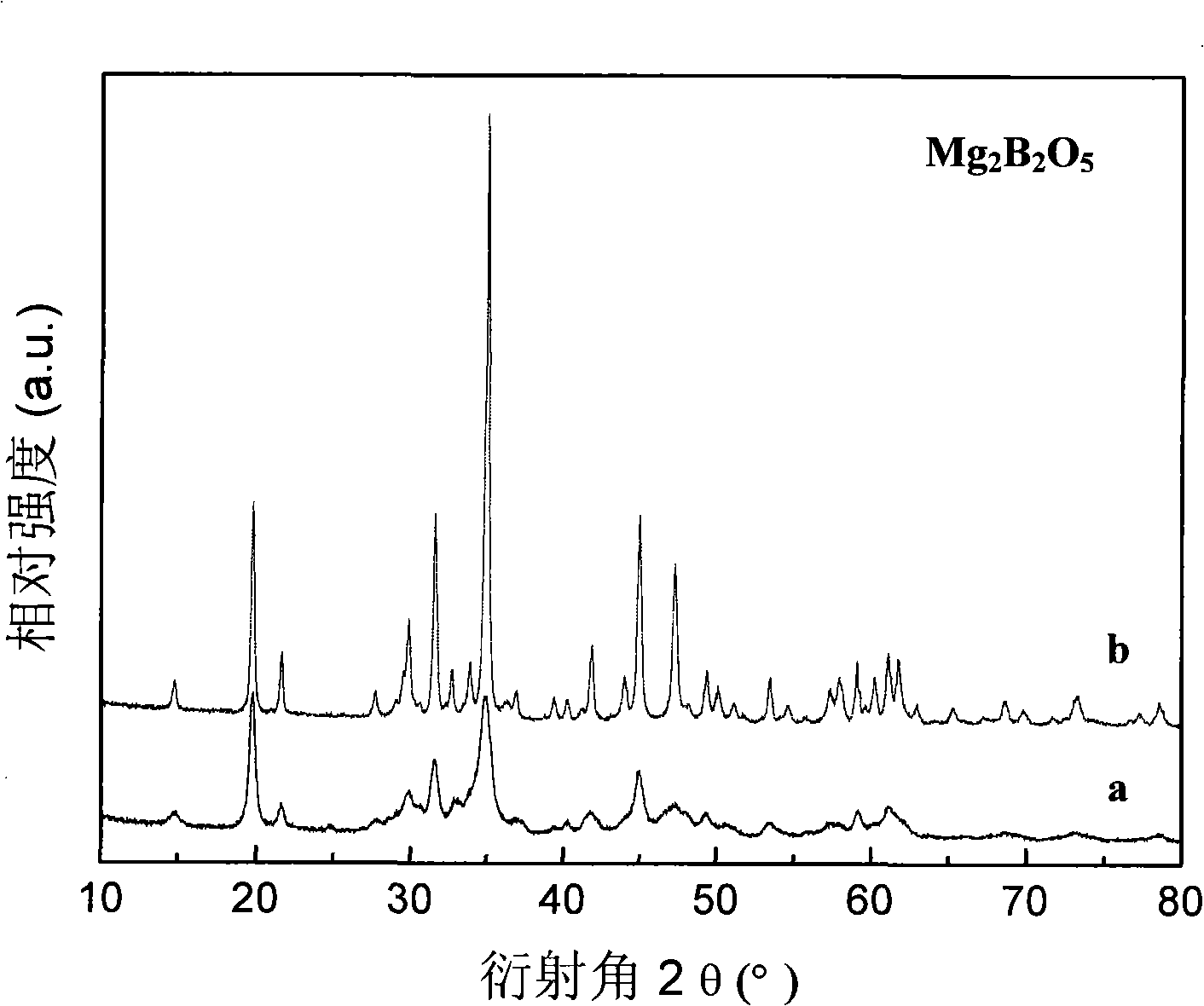

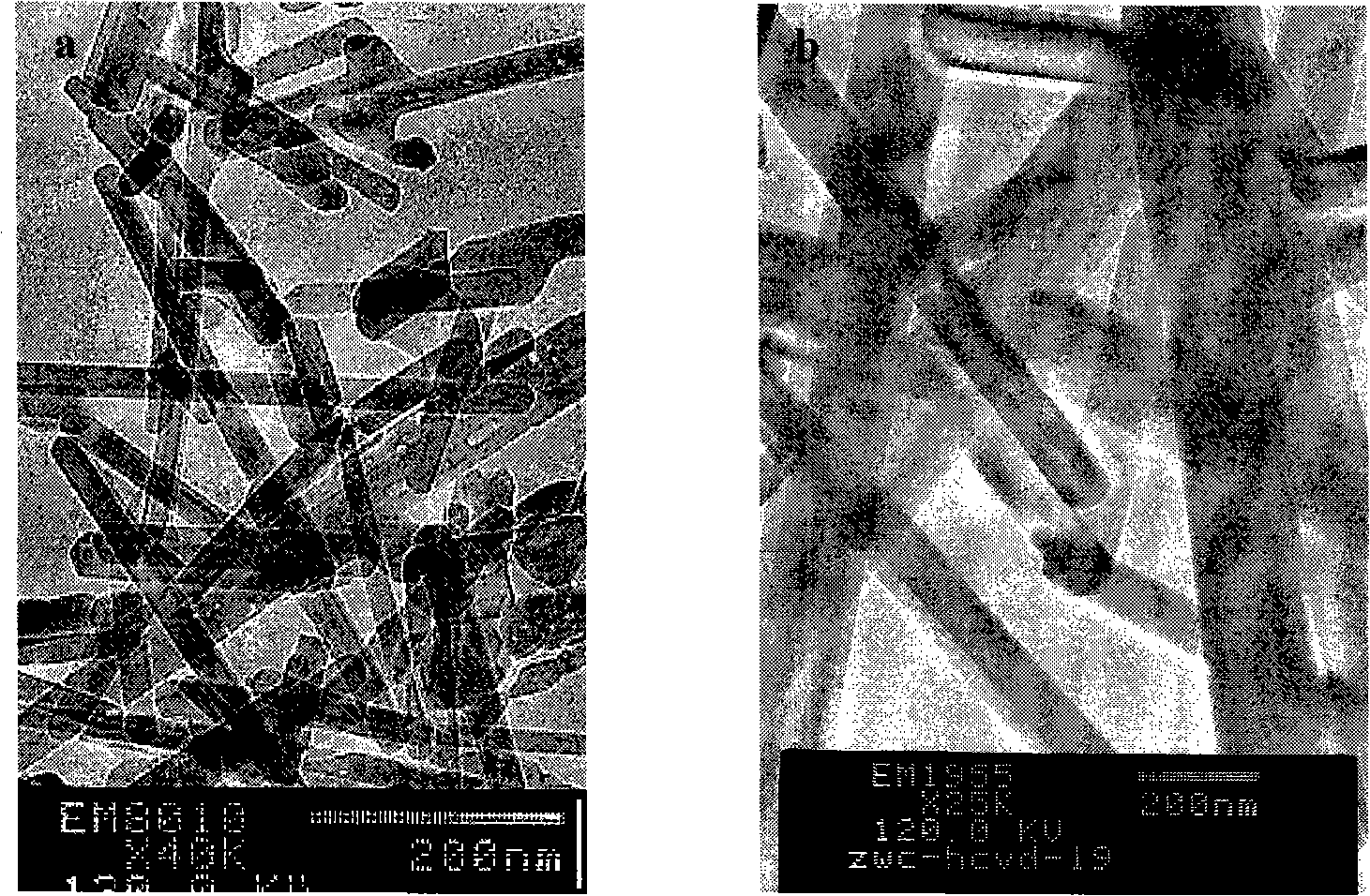

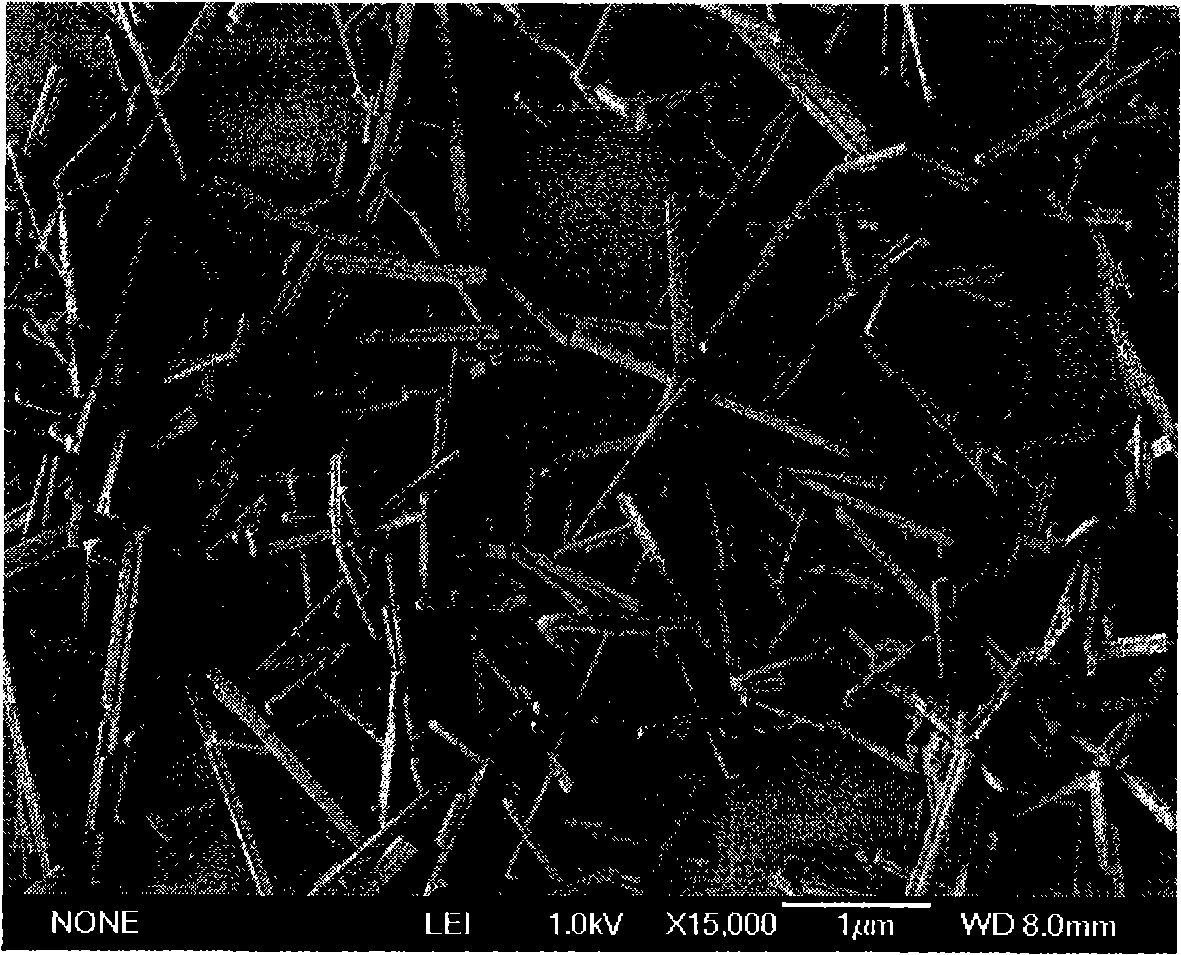

[0017] The invention provides a low-temperature molten salt thermal conversion preparation method for non-porous high-crystalline magnesium borate whiskers. The hydrothermal product basic magnesium borate whiskers is used as a precursor, mixed with a trace amount of inorganic molten salt, and heated in an air atmosphere at 600-750°C. Medium roasting, control the pyrolysis dehydration rate of the precursor by adjusting the heating rate, and at the same time use the small size effect or double salt effect of the nano-flux particles deposited on the surface of the basic magnesium borate whiskers to reduce the melting point of the system, and use the flux seepage to achieve structural reformation and eliminate pores, and then wash, filter, and dry to obtain non-porous, highly crystalline magnesium borate whiskers with regular morphology and good dispersion. The specific steps are as follows:

[0018] 1) prepare 0.5~15wt% molten salt solution, molten salt adopts any one in sodium ch...

Embodiment 2

[0028] Weigh 2.0 grams of hydrothermal product basic magnesium borate whiskers, weigh 0.02 grams of sodium chloride according to its mass ratio of 1%, and dissolve sodium chloride in 4 milliliters of deionized water to prepare a 0.5 wt % sodium chloride solution. Mix basic magnesium borate whiskers and sodium chloride solution, place in a corundum crucible and an air roaster, heat up (10°C / min) to 750°C, and then treat at a constant temperature for 1 hour, then wash, filter, and dry at 100°C for 18 hours , the average length is 0.5μm, the average diameter is 50nm, the aspect ratio is 10, and the specific surface area is 30.5m 2 / g, non-porous high crystalline magnesium borate whiskers with a main content of 98%.

Embodiment 3

[0030] Weigh 2.0 grams of hydrothermal product basic magnesium borate whiskers, weigh 0.6 grams of potassium chloride according to its mass ratio of 30%, and dissolve potassium chloride in 4 milliliters of deionized water to prepare a 15 wt % potassium chloride solution. Mix basic magnesium borate whiskers and potassium chloride solution, place in a corundum crucible and an air roaster, heat up (1°C / min) to 600°C, then treat at a constant temperature for 5 hours, then wash, filter, and dry at 95°C for 20 Hours, the average length is 20μm, the average diameter is 100nm, the aspect ratio is 200, and the specific surface area is 20.8m 2 / g, non-porous high crystalline magnesium borate whiskers with a main content of 98.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com