Process for preparing titanium-based hydroxylapatite/titanium oxide nanotube composite coating

A technology of titanium-based hydroxyapatite and titanium oxide nanotubes is applied in the coating, superimposed layer plating, metal material coating process, etc. The effect of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) Pretreatment: use pure titanium as the substrate, add 4% HF and 5mol / L HNO 3 Etched in the mixed acid solution for 30 seconds, then took it out, cleaned it with distilled water, and dried it at 80°C.

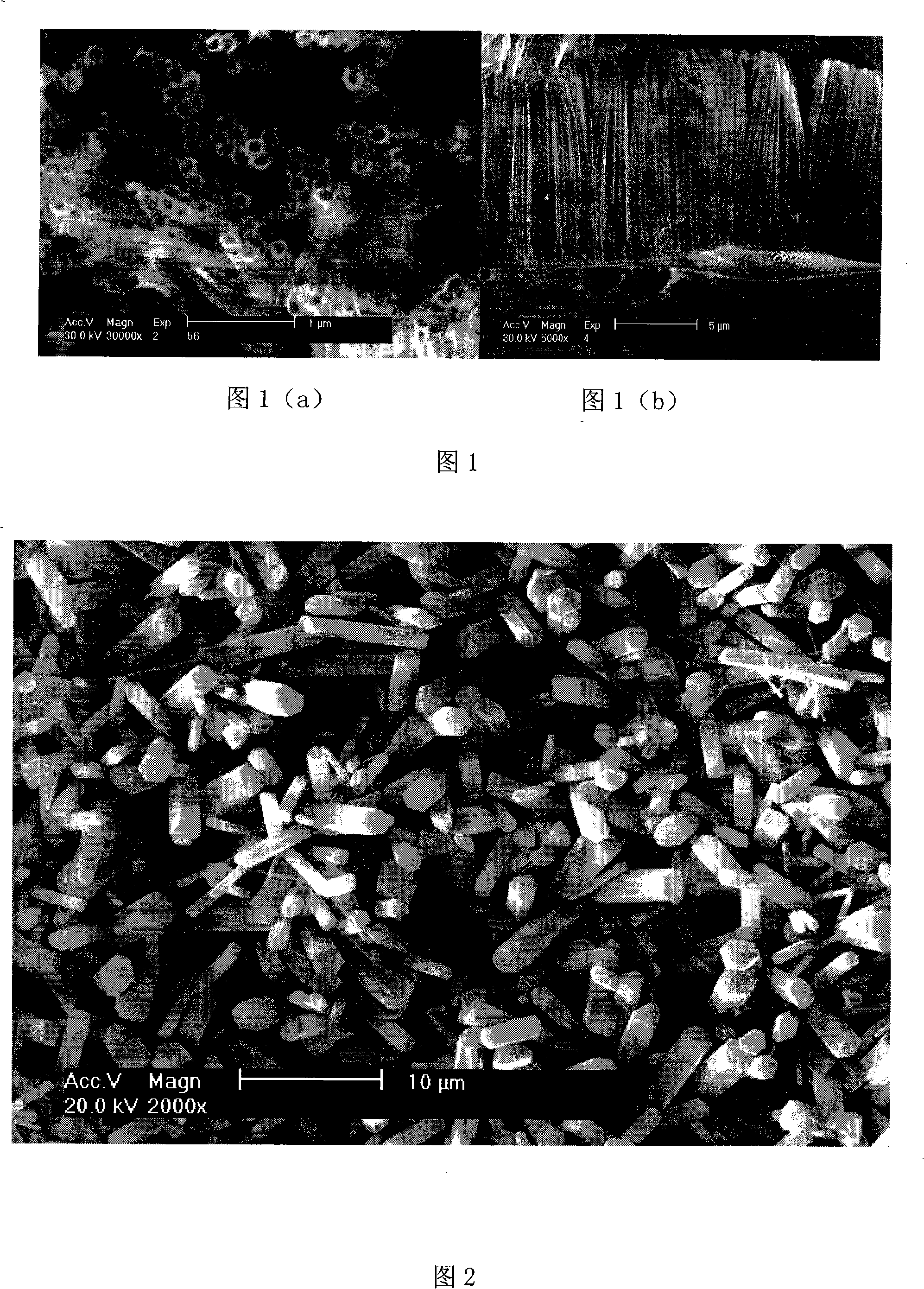

[0019] 2) Anodic oxidation: use pure titanium as the anode, platinum sheet as the cathode, control the distance between the cathode and anode to be 1cm, oxidize in a dimethyl sulfoxide solution containing 2% HF by mass percentage, voltage 60V, and oxidize in a water bath at 20°C for 24h. Then take it out, wash it with distilled water, and dry it at 80°C. The surface morphology observed by scanning electron microscope is shown in Fig. 1 in the accompanying drawings. The diameter of the nanotube is about 170nm, and the wall thickness of the tube is 30nm. From its cross-sectional view, it can be seen that the length of the nanotube tube is about 12 μm.

[0020] 3) Hydrothermal deposition: at 0.1mol / L CaCl 2 , 0.1mol / L NaH 2 PO 4 , In an aqueous solution of 0.2mol / L ...

Embodiment 2

[0022] 1) Pretreatment: use pure titanium as the substrate, add 4% HF and 5mol / L HNO 3 Etched in the mixed acid solution for 30 seconds, then took it out, cleaned it with distilled water, and dried it at 80°C.

[0023] 2) Anodic oxidation: use pure titanium as the anode, platinum sheet as the cathode, control the distance between the cathode and the anode to be 1cm, oxidize in a dimethyl sulfoxide solution containing 1% HF at a voltage of 20V, and oxidize in a water bath at 10°C for 2h. Then take it out, wash it with distilled water, and dry it at 80°C. The diameter of the titanium oxide nanotubes observed by the scanning electron microscope is about 100 nm, and the wall thickness of the tubes is 10 nm. From its cross-sectional view, it can be seen that the length of the nanotube tube is about 2 μm.

[0024] 3) Hydrothermal deposition: at 0.25mol / L CaCl 2 , 0.5mol / L NaH 2 PO 4 , 0.2mol / L EDTA aqueous solution, use 1mol / L NaOH to adjust the pH value of the solution to 4, u...

Embodiment 3

[0026] 1) Pretreatment: use pure titanium as the substrate, add 4% HF and 5mol / L HNO 3 Etched in the mixed acid solution for 30 seconds, then took it out, cleaned it with distilled water, and dried it at 80°C.

[0027] 2) Anodic oxidation: use pure titanium as the anode, platinum sheet as the cathode, control the distance between the cathode and the anode to be 1cm, oxidize in a dimethyl sulfoxide solution containing 4% HF by mass percentage, a voltage of 70V, and oxidize in a water bath at 30°C for 10h. Then take it out, wash it with distilled water, and dry it at 80°C. The diameter of the titanium oxide nanotube is about 150nm and the thickness of the tube wall is 20nm as observed by scanning electron microscope. From its cross-sectional view, it can be seen that the length of the nanotube tube is about 20 μm.

[0028] 3) Hydrothermal deposition: at 0.5mol / L CaCl 2 , 0.25mol / L NaH 2 PO 4, In an aqueous solution of 0.2mol / L EDTA, adjust the pH value of the solution to 6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com