Large-scale mold module and method for manufacturing same

A manufacturing method and mold technology, applied in manufacturing tools, heat treatment process control, heat treatment equipment, etc., can solve problems such as the inability to meet large-scale mold module manufacturing, high module manufacturing costs, and oil mist emission, and improve product competitiveness. And the effect of share, reasonable ratio and investment saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. A large plastic mold module, the weight percent distribution ratio of its chemical composition is: C0.23wt%, Si0.12wt%, Mn1.59wt%, Cr1.30wt%, V0.25wt%, Mo0.63wt%, Ni0 .99wt%, S0.011wt%, P0.013wt%, the rest is Fe;

[0037] 2. After primary smelting in electric arc furnace and scouring outside the furnace, it is cast into a 25-ton large steel ingot; the steel ingot is heated to 1200 °C in the forging heating furnace at a heating rate of 95 °C / h and then kept for 6 hours; the forging temperature is 1110 °C; stop forging The temperature is 950°C.

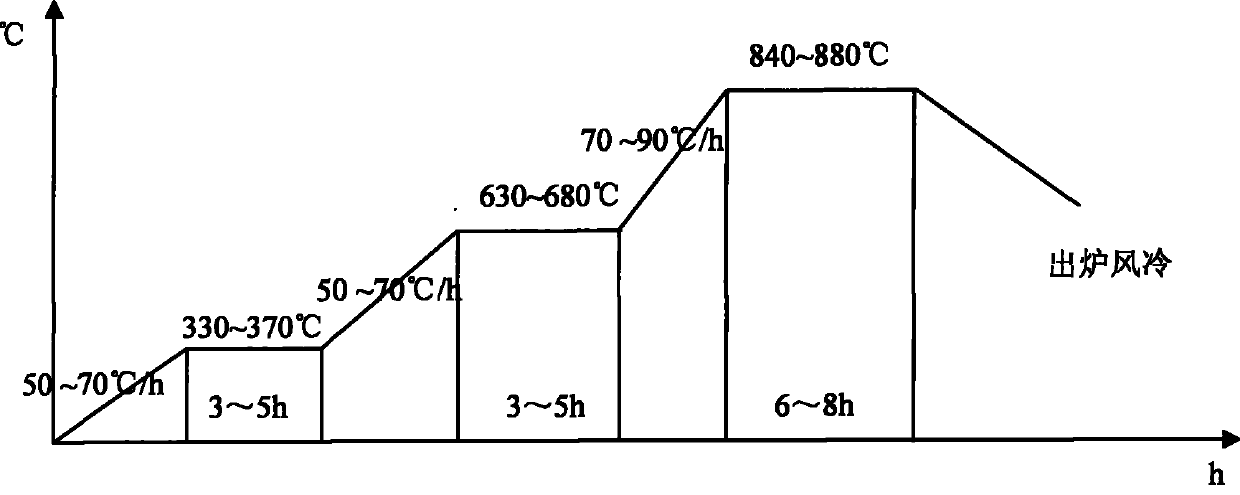

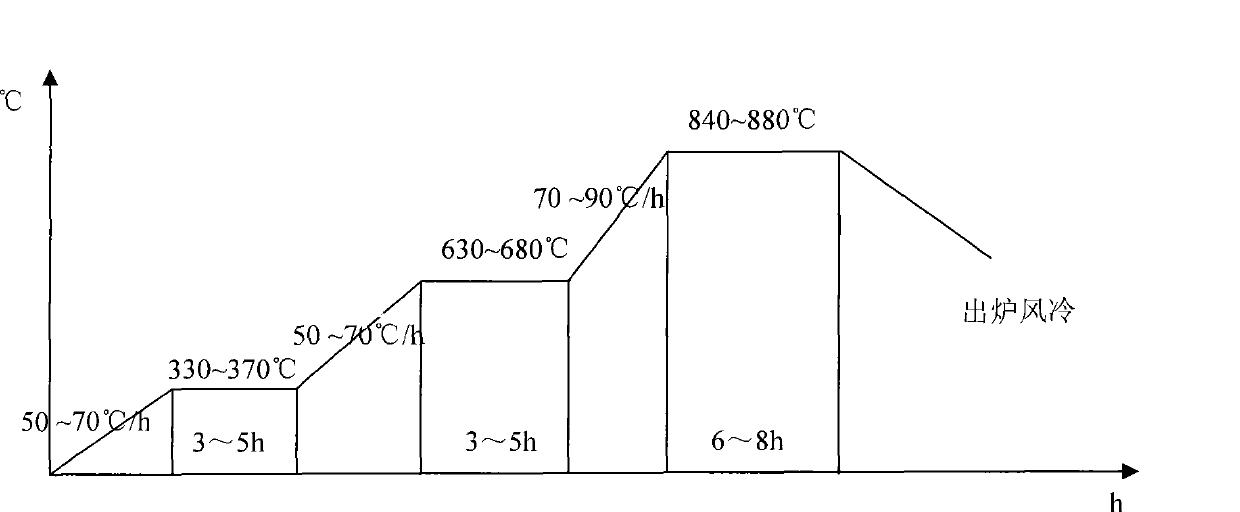

[0038] After forging, carry out the pre-hardening heat treatment of the plastic mold module. First, put the plastic mold module into the quenching furnace and heat it to 345℃ at a heating rate of 55℃ / h, then keep it for 3.5 hours; then heat it at a heating rate of 55℃ / h to 645℃ Then keep it warm for 3.5 hours; then heat it up to 855°C at a heating rate of 75°C / h and keep it warm for 6.5 hours, then remove it from the quenchin...

Embodiment 2

[0042] 1. A large plastic mold module, the weight percent distribution ratio of its chemical composition is: C0.20wt%, Si0.08wt%, Mn1.55wt%, Cr1.35wt%, V0.12wt%, Mo0.60wt%, Ni0 .90wt%, S0.015wt%, P0.010wt%, the rest is Fe;

[0043] 2. Casting 25 tons of large steel ingots after primary smelting in electric arc furnace and refining outside the furnace; the steel ingots are heated to 1220°C in the forging heating furnace at a heating rate of 80°C / h and then kept for 5 hours; the forging start temperature is 1090°C; the forging stop temperature 900°C.

[0044] After forging, perform pre-hardening heat treatment of the plastic mold module. First, put the plastic mold module into a quenching furnace and heat it to 330℃ at a heating rate of 50℃ / h, then keep it for 3 hours; then heat it at a heating rate of 50℃ / h to 650℃ Then keep it warm for 4 hours; then heat it up to 850°C at a heating rate of 70°C / h and keep it warm for 7 hours, then remove it from the quenching furnace and cool...

Embodiment 3

[0048] 1. A large plastic mold module, the weight percent distribution ratio of its chemical composition is: C0.22wt%, Si0.11wt%, Mn1.70wt%, Cr1.20wt%, V0.35wt%, Mo0.55wt%, Ni1 .20wt%, S0.008wt%, P0.020wt%, the rest is Fe;

[0049] 2. After primary smelting in electric arc furnace and scouring outside the furnace, it is cast into a 25-ton large steel ingot; the steel ingot is heated to 1200 °C in the forging heating furnace at a heating rate of 120 °C / h and then kept for 7 hours; the forging start temperature is 1150 °C; the forging stop temperature 850°C.

[0050] After forging, carry out pre-hardening heat treatment of the plastic mold module. First, put the plastic mold module into the quenching furnace and heat it to 370℃ at a heating rate of 60℃ / h, then keep it for 5 hours; then heat it at a heating rate of 70℃ / h to 630℃ Then keep it warm for 5 hours; then heat it up to 840°C at a heating rate of 80°C / h and keep it warm for 8 hours, then remove it from the quenching furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com