Ni-base superalloy complex gradient coating and preparation technique thereof

A gradient coating and coating technology, which is applied in the direction of metal material coating process, coating, superimposed layer plating, etc., can solve the problems of increasing the weak link of the coating system and increasing the multi-layer interface, etc., and achieve long service life , prolong the service time, delay the effect of degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

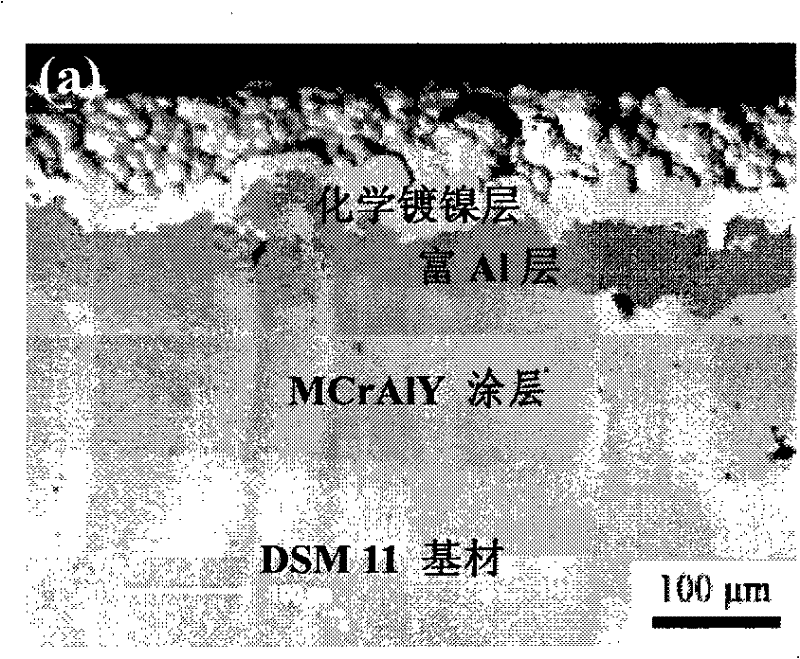

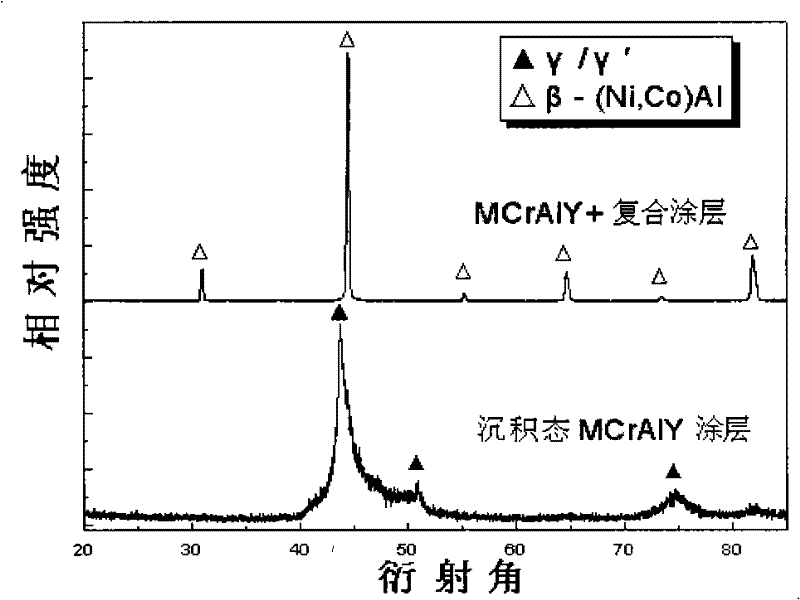

Embodiment 1

[0028]The substrate is directionally solidified nickel-based superalloy DSM11, and its composition is as follows (mass percentage): Co: 9.5, Cr: 14, W: 3.8, Mo: 1.5, Al: 3, Ti: 4.8, Ta: 2.8, C: 0.1 , Ni: margin. The conventional MCrAlY coating is deposited on the substrate by arc ion plating (AIP). The composition of the MCrAlY target material is as follows (in mass percentage): Co: 32; Cr: 20; Al: 8; Y: 0.5; Si: 1; B: 0.03, Ni: margin. The specific operation process is as follows: the sample is pretreated before deposition, that is, the substrate sample is polished to Ra=0.4μm, and the 200-mesh hollow glass pellet is used for wet sandblasting, followed by metal detergent, deionized water, acetone ultrasonic Wash for 15 minutes, rinse with alcohol and dry for later use. The domestic MIP-8-800 multi-arc ion plating equipment is used to deposit conventional MCrAlY coatings, and the vacuum is pre-evacuated to 7×10 -3 Pa, Ar gas was introduced during bombardment and deposition,...

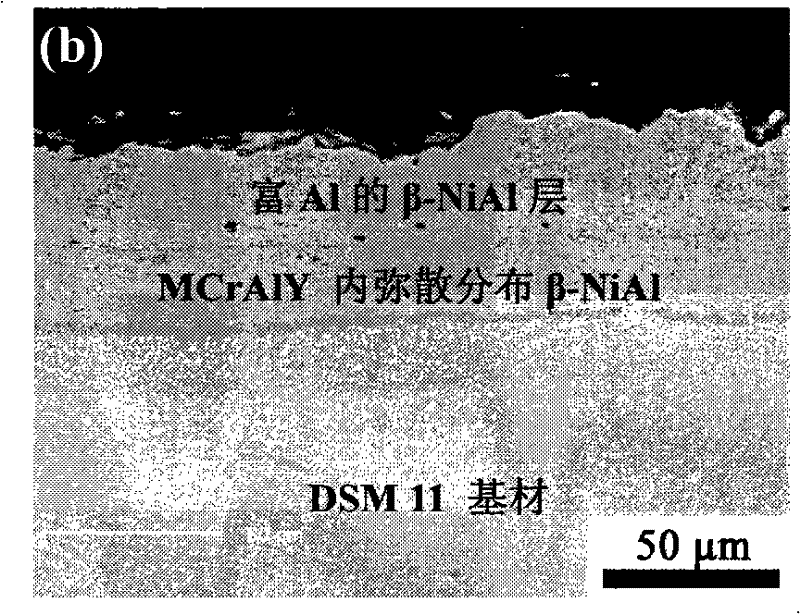

Embodiment 2

[0032] The base material is directionally solidified Ni-based superalloy DZ125, and its composition is as follows (mass percentage): Co: 10, Cr: 9, W: 7, Al: 5, Ti: 2.5, Ta: 3.5, C: trace, Ni: surplus quantity. The composition and deposition process of the conventional MCrAlY coating are the same as in Example 1, and the thickness of the obtained conventional MCrAlY coating is about 50 μm. NH should be mixed with Al before low pressure CVD 4 Cl drying, this embodiment adopts the method of 120 ℃ normal pressure insulation for 12h. 96wt% FeAl powder (Al content is 48wt%, powder particle size is about 250 mesh) and 4wt% dried NH 4 Cl, fully stirred and mixed evenly, put it into the CVD furnace cavity, vacuumize to 0.1 atmosphere (atm), keep it at 950°C for 5h, and obtain dry FeAl powder after cooling in the furnace. Hang the deposited or annealed MCrAlY sample into a low-pressure CVD furnace, put 800g of dry FeAl powder and 25g of dry NH 4 Cl, vacuum pumped to 0.08 atm, after...

Embodiment 3

[0035] The base material is Co-based superalloy K40, and its nominal composition is (mass percentage): 10.5% Ni, 25.5% Cr, 7.5% W, 0.45% C, Co balance, and the sample size is 15×10×1.5mm 3 . The MCrAlY+Al(SiY) composite coating was co-deposited by domestic MIP-8-800 multi-arc ion plating equipment. The composition of the MCrAlY alloy target is as follows (by mass percentage), Co: 32; Cr: 20; Al: 10; Y: 0.5; Si: 1; B: 0.03, Ni: the balance. The sample is pretreated before deposition, that is, the substrate sample is polished to Ra=0.4 μm, wet sandblasting with 200-mesh hollow glass pellets, and then ultrasonically cleaned with metal detergent, deionized water, and acetone for 15 minutes, and washed with alcohol Rinse and tumble dry for later use. MIP-8-800 arc ion plating equipment was used to deposit conventional MCrAlY coatings, pre-evacuated to 7×10 -3 Pa, Ar gas was introduced during bombardment and deposition, and the vacuum degree was 2×10 -1 Pa. Clean the sample by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com