Method for removing mercury vapor in gas

A mercury vapor and gas technology, which is applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of catalyst poison, harmful to human body, animals and plants, and corrosion of pipelines, etc., and achieves the effect of high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

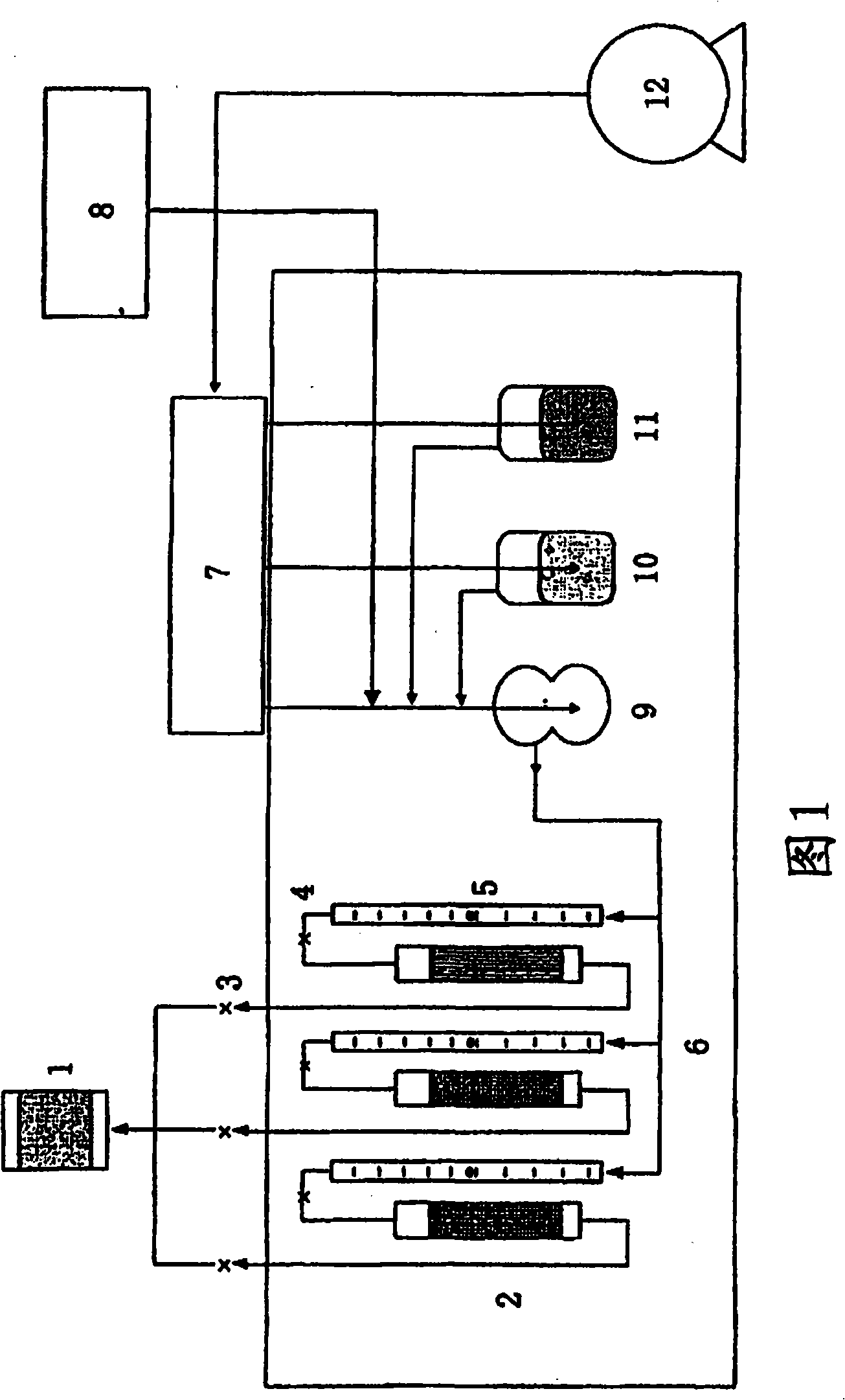

Method used

Image

Examples

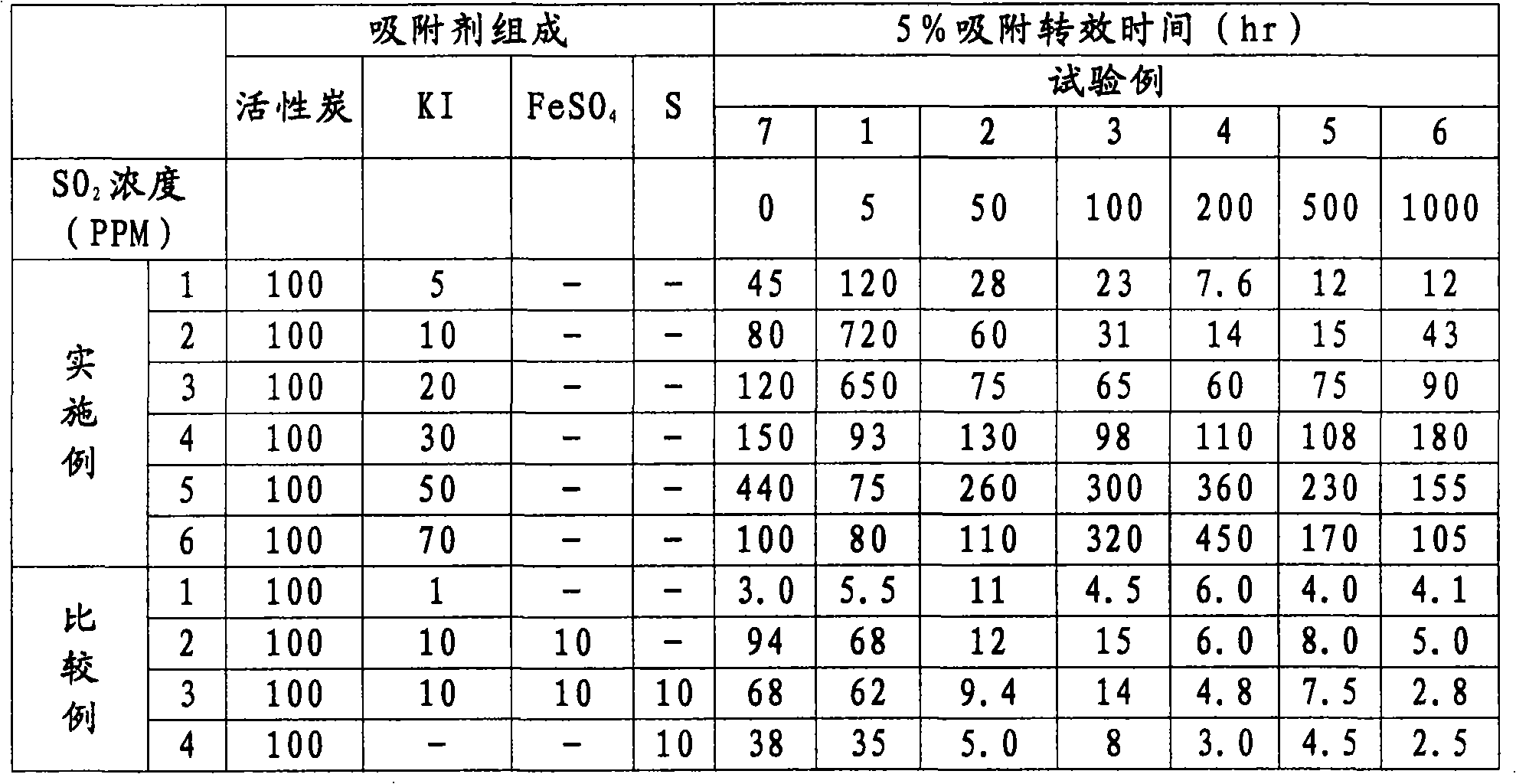

Embodiment 1

[0057] 5 g of potassium iodide was dissolved in 40 g of distilled water to prepare a potassium iodide aqueous solution. The specific surface area measured by BET method is 1130m 2 / g, the average pore diameter is 1.71nm, the pore volume is 0.482ml / g, the water retention rate is 42%, and the crushed coconut shell activated carbon 100g of the particle diameter is 0.71~1.00mm is packed in the polypropylene container, while using While agitating with a table mixer (100-300rpm), all of the potassium iodide aqueous solution prepared in advance was sprayed and attached at 25°C, and then dried at 110°C to obtain an adsorbent composed of activated carbon loaded with potassium iodide.

Embodiment 2

[0059] 10 g of potassium iodide was dissolved in 40 g of distilled water to prepare a potassium iodide aqueous solution. The crushed coconut shell activated carbon 100g that is used in the embodiment 1 is packed in the polypropylene container, stirs (100~300rpm) with the desktop mixer on the one hand, all the potassium iodide aqueous solution prepared in advance is sprayed on one side, then under 110 ℃ After drying, an adsorbent consisting of activated carbon loaded with potassium iodide was obtained.

Embodiment 3

[0061] 20 g of potassium iodide was dissolved in 40 g of distilled water to prepare a potassium iodide aqueous solution. The crushed coconut shell activated carbon 100g that is used in the embodiment 1 is packed in the polypropylene container, stirs (100~300rpm) with the desktop mixer on the one hand, all the potassium iodide aqueous solution prepared in advance is sprayed on one side, then under 110 ℃ After drying, an adsorbent consisting of activated carbon loaded with potassium iodide was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com