Predetermined pattern manufacturing method

A technology of predetermined pattern and production method, applied in conductive pattern formation, printed circuit manufacturing, electrical components, etc., can solve problems such as insufficient uniformity, inaccurate predetermined pattern, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

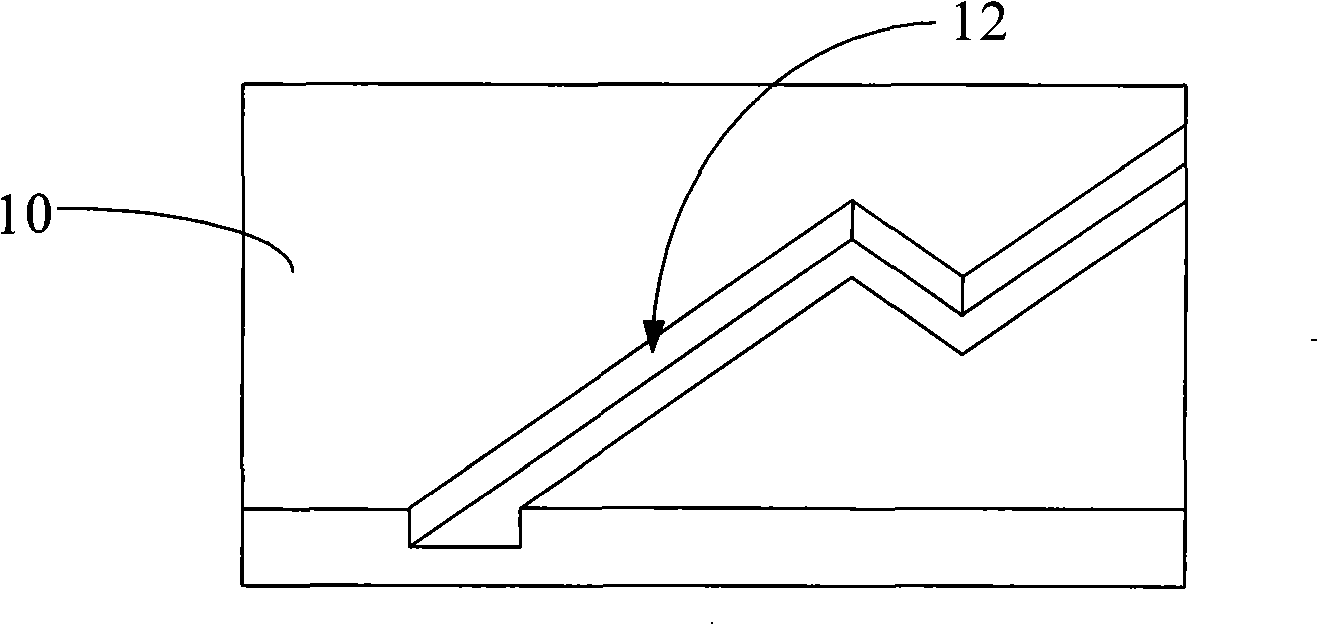

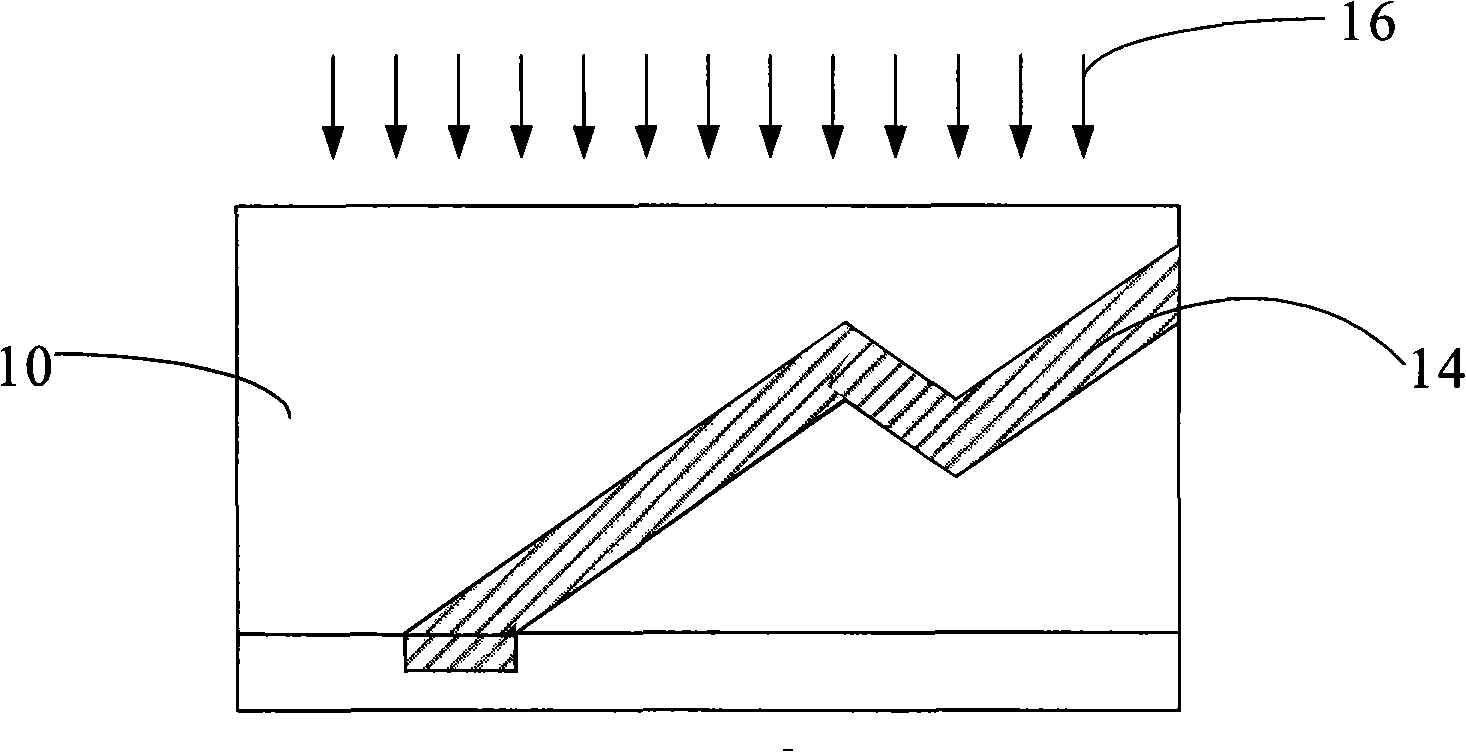

[0019] Please refer to FIGS. 1A-1C . FIGS. 1A-1C are schematic diagrams of a method for making a predetermined pattern according to the present invention. As shown in FIG. 1C , the manufacturing method of the predetermined pattern of the present invention mainly can form the predetermined pattern on the insulating substrate 10 of the printed circuit board. In addition to the circuit 14 shown in FIG. 1C , the predetermined pattern can also be a mark (such as a serial number of a product, a name of a manufacturer, etc.), and an alignment hole.

[0020] To put it simply, in the method for making the predetermined pattern of the present invention, it is first necessary to provide the insulating substrate 10 of the printed circuit board, and according to the design of the predetermined pattern, the predetermined pattern ( Such as line, product serial number, manufacturer's name, etc.). The following will take the fabrication of the circuit 14 as shown in FIG. 1C as an example for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com