Epoxy cast dry transformer

A technology of dry-type transformers and epoxy casting, which is applied in the field of transformers, and can solve the problems of poor performance against longitudinal impact interference, easy partial discharge, and small longitudinal capacitance, and achieve strong overload capacity and sudden short-circuit resistance Strong, strong temperature characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

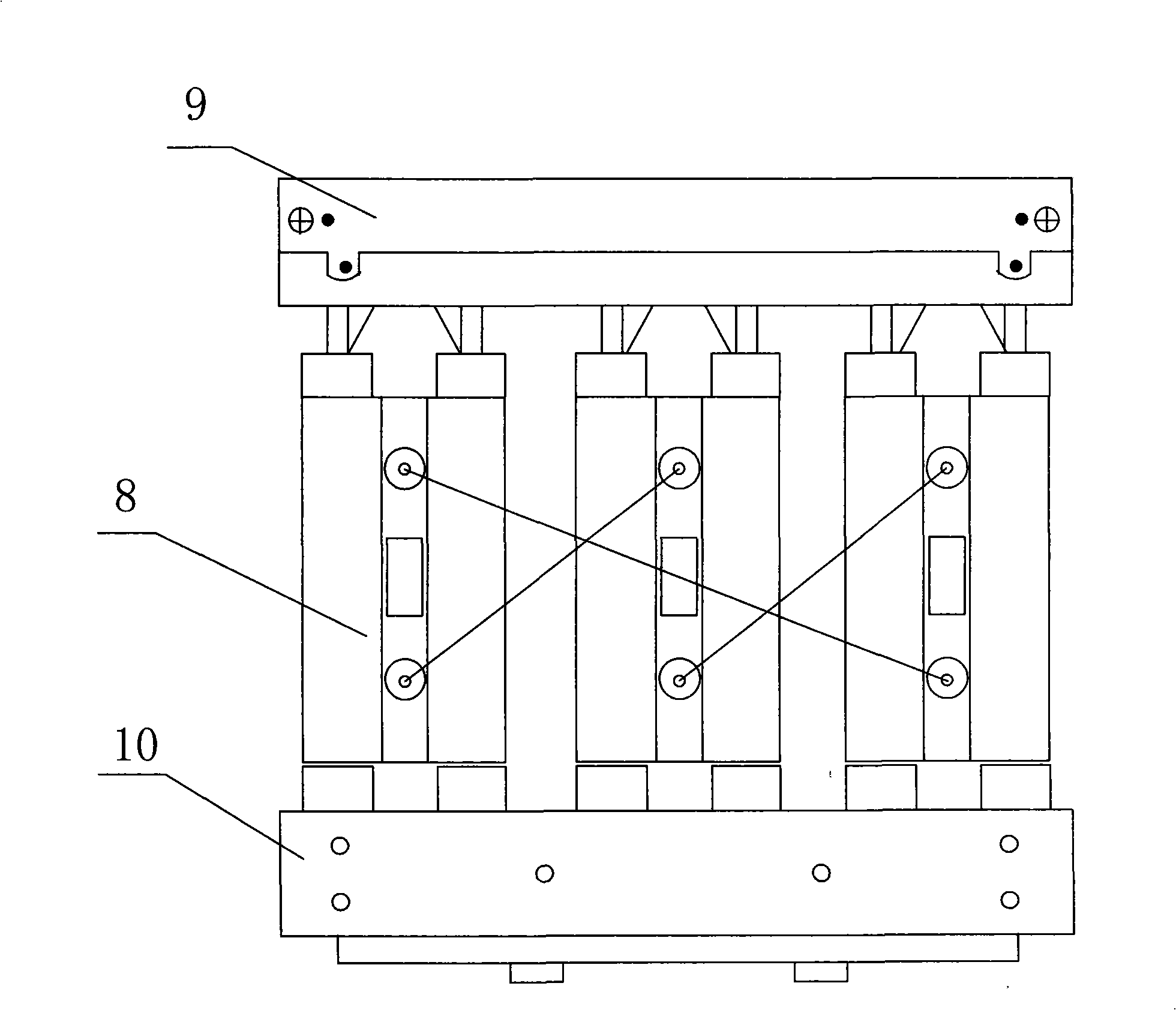

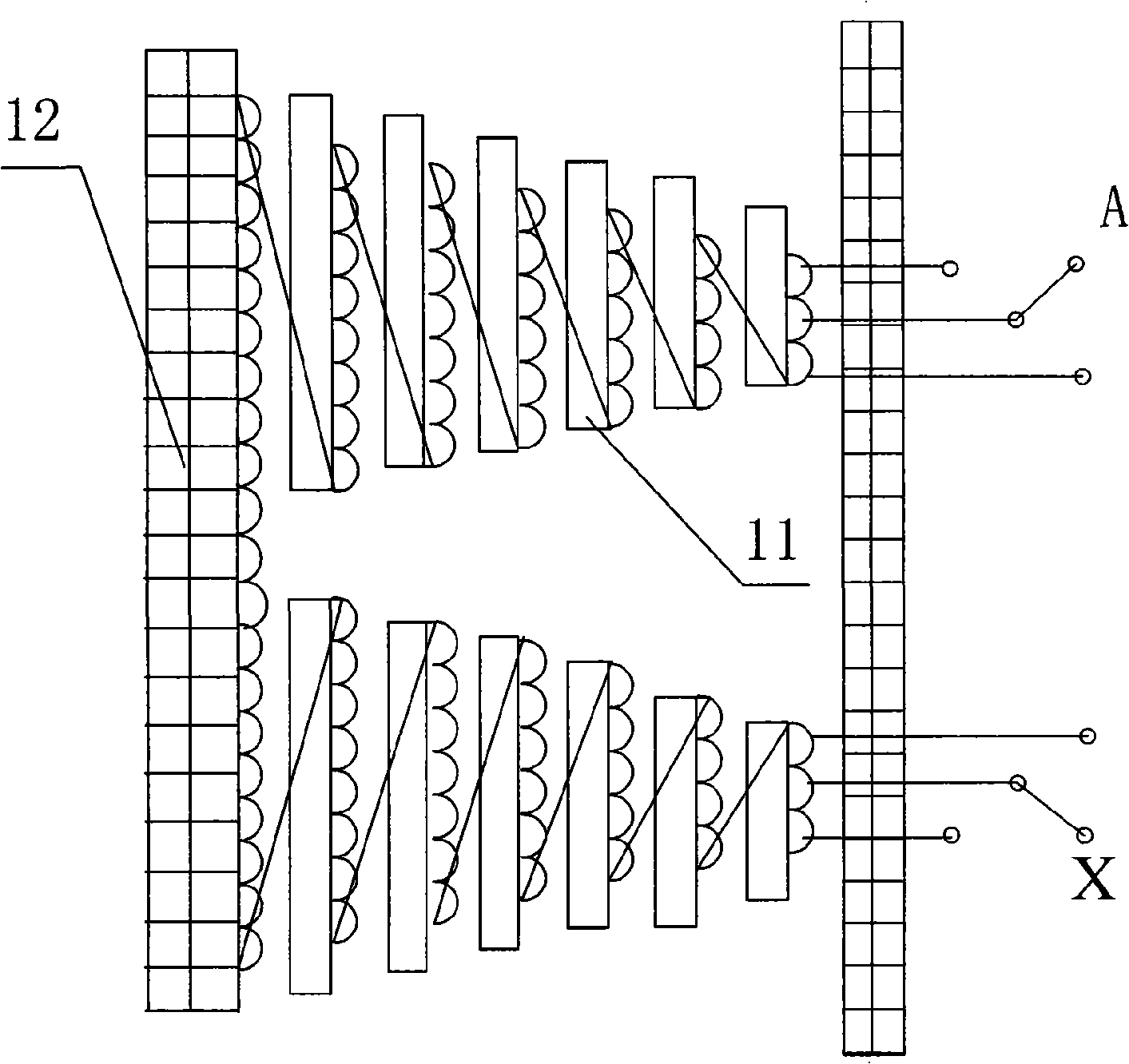

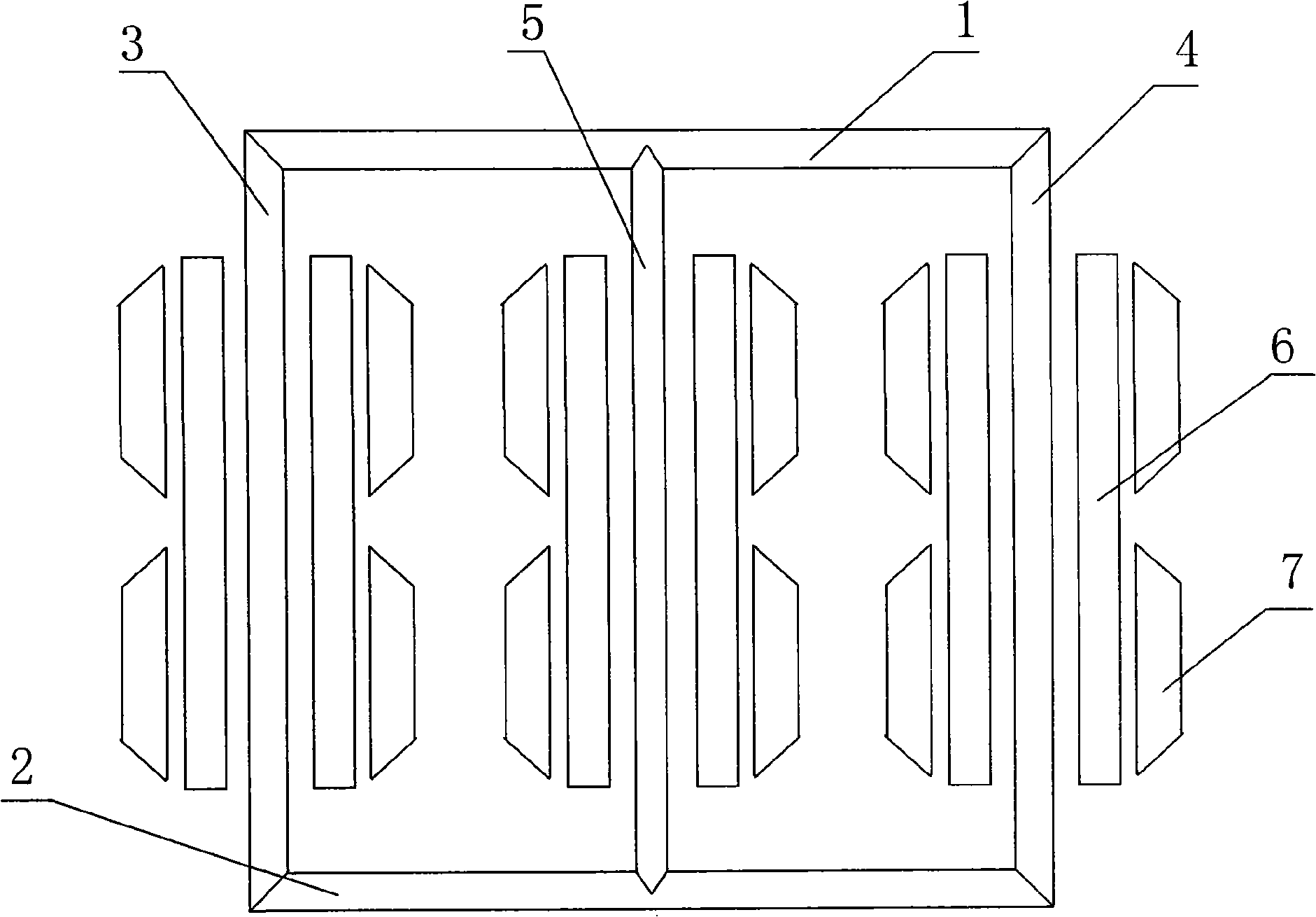

[0029] The production and production of epoxy cast dry-type transformers is a highly technological technology, such as Figure 1-3 As shown, the epoxy cast dry-type transformer includes a low-voltage winding 6, two high-voltage windings 7, and an iron core.

[0030] The iron core is provided with an upper yoke 1 and a lower yoke 2, and a left column 3 is arranged between the left ends of the upper and lower yokes 1 and 2, and the upper and lower ends of the left column 3 are connected with the upper and lower yokes 1 and 2 respectively. The left end of 2 is overlapped; the right column 4 is arranged between the right ends of the upper and lower yokes 1 and 2, and the upper and lower ends of the right column 4 are respectively overlapped with the right ends of the upper and lower yokes 1 and 2; The middle part of the lower yokes 1 and 2 is provided with a center column 5, and the upper and lower ends of the center column 5 are overlapped with the middle parts of the upper and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com