Engine fuel cylinder inner direct ejection device

A technology for injection devices and engines, which is applied in the direction of fuel injection devices, engine components, machines/engines, etc., can solve the problems of oil dripping, vaporization, and low lubrication of injectors, so as to prevent oil dripping, improve response characteristics, and ensure The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

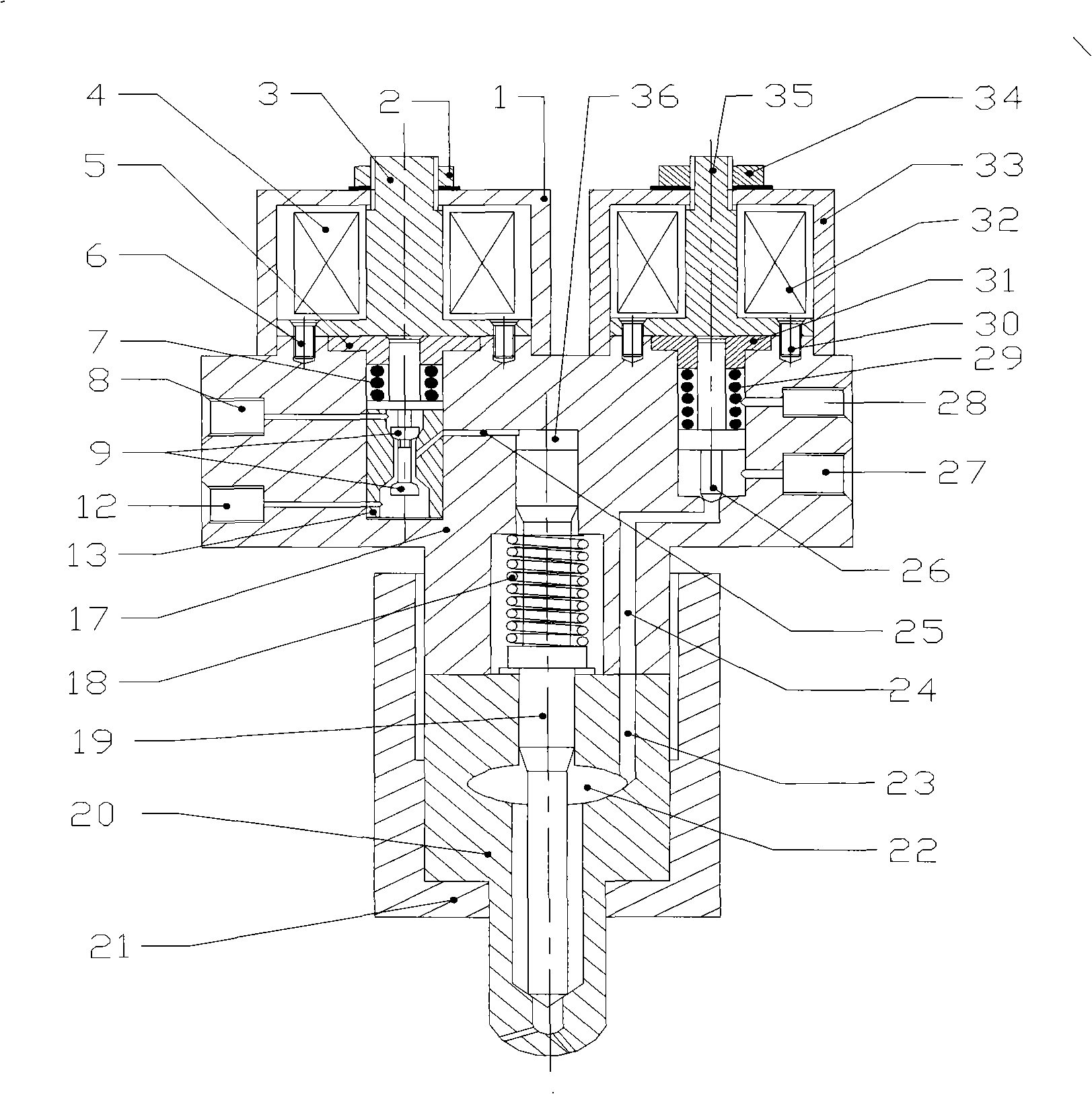

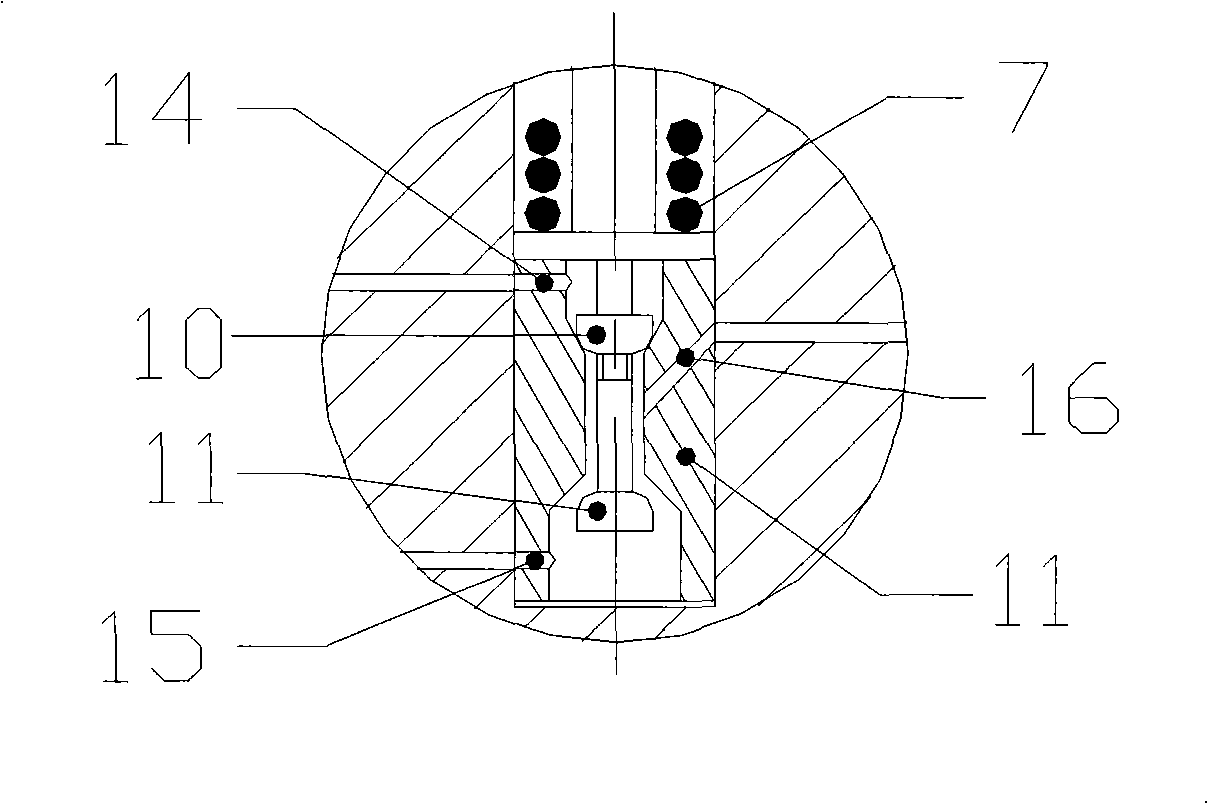

[0015] like figure 1 , 2 As shown, the direct injection device in the engine fuel cylinder includes a back pressure control high-speed solenoid valve, a fuel control solenoid valve, an injector body, a fuel injection nozzle, a back pressure control high-speed solenoid valve and a fuel control solenoid valve installed on the injector body. In the upper part, the fuel injector is fixed on the lower part of the injector body. The injector body 17 includes the working oil return channel 8, the working oil inlet channel 12, the high pressure oil channel 24 of the injector body, the fuel oil inlet channel 27, and the fuel oil. The oil return passage 28, the back pressure chamber 36, the upper part of the injector body 17 is provided with a double valve core fixing chamber and a single valve core fixing chamber, the lower part of the fuel injector body 17 is provided with a needle valve fixing chamber, and both sides of the fuel injector body 17 are provided There are respectively a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com