Method for synthesizing beta-SiC nano-wire

A synthesis method and nanowire technology, which is applied in the field of synthesis of β-SiC nanowires, can solve the problems of high cost and low purity of β-SiC nanowires, and achieve the effects of high surface activity, high specific surface area, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

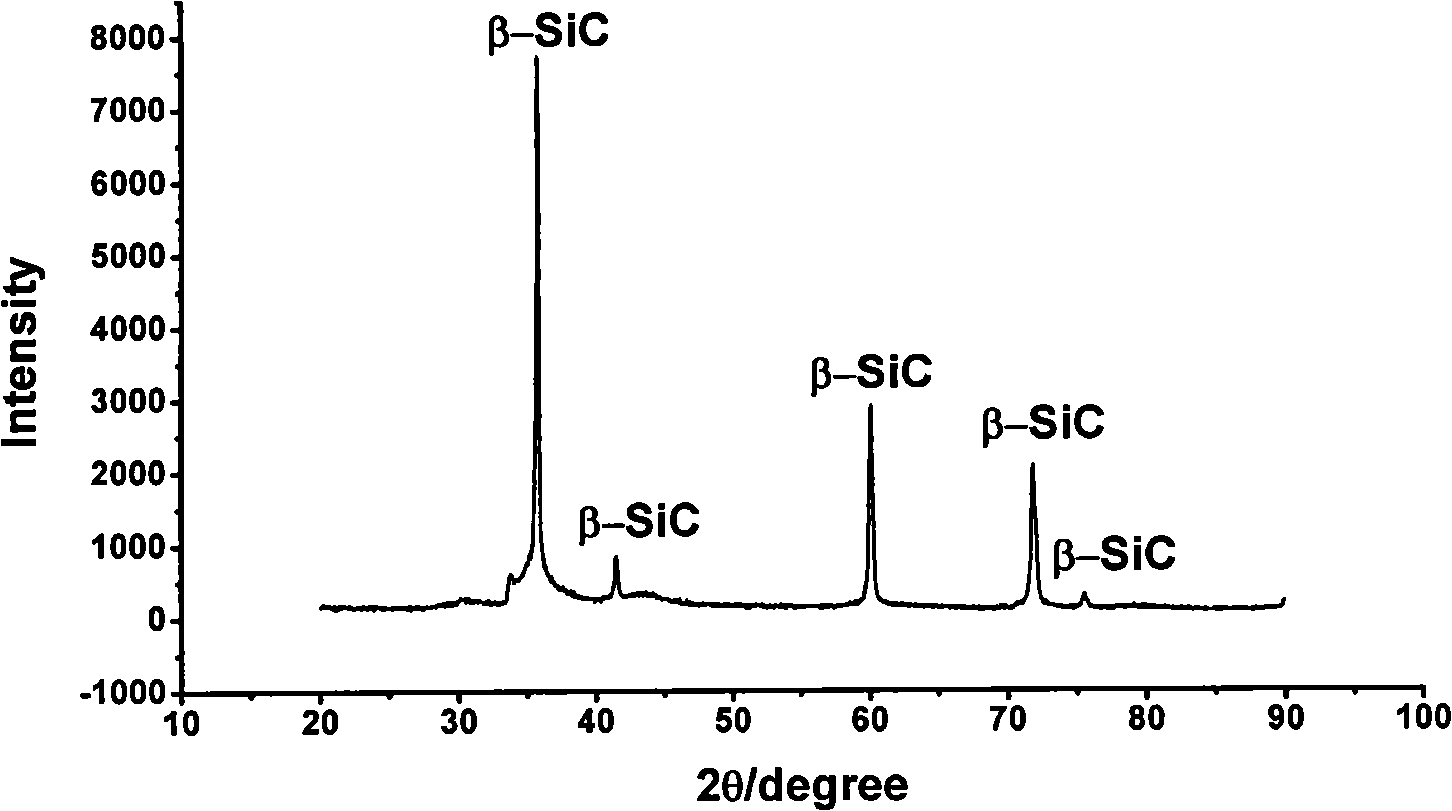

Image

Examples

Embodiment 1

[0013] Embodiment 1: the present embodiment adopts pine wood as biological activated carbon raw material

[0014] 1) Preparation of bioactivated carbon flakes: first process pine wood into flakes with a thickness of 1mm, wash the flakes with water, and dry them in a blast drying oven at a drying temperature of 70°C for 24 hours, and then The dried flakes were carbonized at 900°C, the heating rate was 60°C / h, and kept for 10 hours to obtain biological activated carbon flakes;

[0015] 2) Preparation of reaction powder: mix diatomaceous earth and silicon powder at a mass ratio of 1:1, and ball mill;

[0016] 3) Preparation of β-SiC nanowires: place the reaction powder in a corundum crucible or a graphite crucible, insert a bioactive carbon sheet into the crucible, cover the crucible mouth with carbon felt, put the crucible into a vacuum sintering furnace and heat up to 1400°C, heat preservation for 1 hour, control the furnace pressure below 100Pa, take out the bio-activated car...

Embodiment 2

[0017] Embodiment 2: the present embodiment adopts pine wood as biological activated carbon raw material

[0018] 1) Preparation of biological activated carbon flakes: first process pine wood into flakes with a thickness of 3mm, wash the flakes with water, and dry them in a blast drying oven at a drying temperature of 70°C for 24 hours, and then The dried flakes are carbonized at 1000°C, the heating rate is 30°C / h, and the heat preservation is 8 hours to obtain biological activated carbon flakes;

[0019] 2) Preparation of reaction powder: mix diatomaceous earth and silicon powder at a mass ratio of 1:1.3, and ball mill;

[0020] 3) Preparation of β-SiC nanowires: place the reaction powder in a corundum crucible or a graphite crucible, insert a bioactive carbon sheet into the crucible, cover the crucible mouth with carbon felt, put the crucible into a vacuum sintering furnace and heat up to 1300°C, heat preservation for 1.5 hours, control the furnace pressure below 100Pa, tak...

Embodiment 3

[0021] Embodiment 3: present embodiment adopts moso bamboo as biological activated carbon raw material

[0022] 1) Preparation of biological activated carbon flakes: first process the moso bamboo into flakes with a thickness of 2mm, wash the flakes with water, and dry them in a blast drying oven at a drying temperature of 70°C for 24 hours, and then The dried flakes were carbonized at 930°C, the heating rate was 50°C / h, and they were kept for 9.5 hours to obtain biological activated carbon flakes;

[0023] 2) Preparation of reaction powder: mix diatomaceous earth and silicon powder at a mass ratio of 1:1.5, and ball mill;

[0024] 3) Preparation of β-SiC nanowires: place the reaction powder in a corundum crucible or a graphite crucible, insert a bioactive carbon sheet into the crucible, cover the crucible mouth with carbon felt, put the crucible into a vacuum sintering furnace and heat up to 1200°C, keep warm for 2 hours, control the furnace pressure below 100Pa, take out the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com