Thermal contraction bag for packaging cheese

A technology of heat shrinkage and cheese, which is applied in the field of packaging materials and plastic products, can solve the problems of large shrinkage force, low shrinkage rate, poor barrier property, etc., and achieve the effects of impact strength resistance, good heat sealing performance, and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

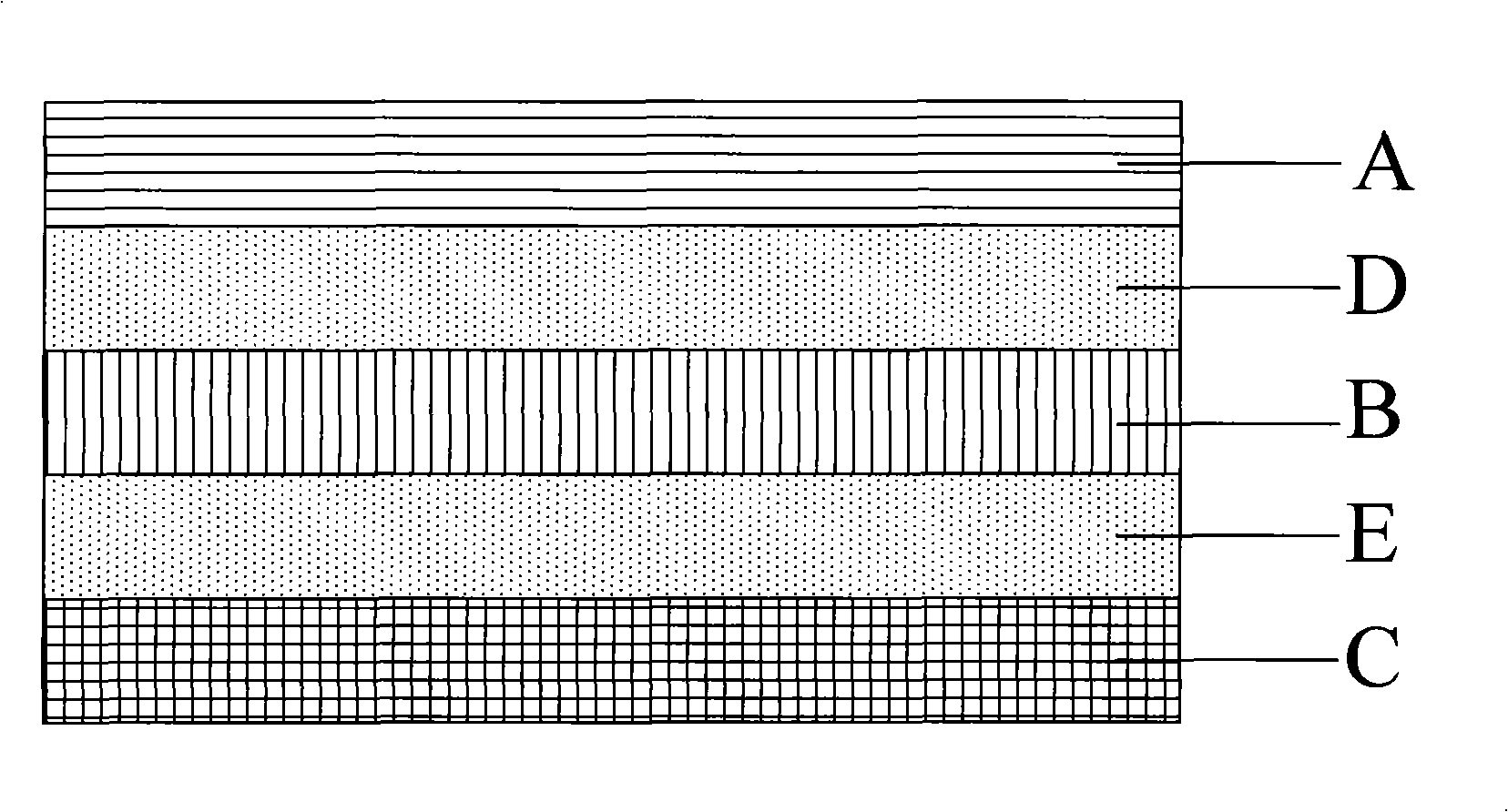

[0023] First prepare the raw materials of each layer, core layer B: 98kg of VDC-MA copolymer and 2kg of epoxidized soybean oil. Surface layer A: 40kg of ethylene-propylene copolymer and 60kg of ethylene-EBA copolymer, the density of ethylene-propylene copolymer is 0.917g / cm 3 . Heat seal layer C: 60kg of ethylene-butene copolymer and 40kg of VLDPE, the density of ethylene-butene is 0.89g / cm 3 , the density of VLDPE is 0.918g / cm 3 . Adhesive layer D and adhesive layer E: 12kg of EVA with a density of 0.93g / cm 3 .

[0024] The raw materials of each layer are added to the extruder of each layer to melt and plasticize, and then enter a multi-layer co-extruded circular die to distribute the melt to form a multi-layer circular melt tube; The body tube blank is cooled and formed by vacuum sizing, and then enters the hot water tank to be heated to a suitable blowing temperature, and the compressed air is filled between two pairs of nip rollers for horizontal blowing and longitudi...

Embodiment 2

[0026] First prepare the raw materials of each layer, core layer B: 98kg of VDC-MA copolymer and 2kg of epoxidized soybean oil. Surface layer A: 50kg of ethylene-propylene copolymer and 50kg of ethylene-EEA copolymer, the density of ethylene-propylene copolymer is 0.88g / cm 3 . Heat seal layer C: 80kg of ethylene-hexene-1 copolymer and 20kg of LMDPE, the density of ethylene-hexene-1 copolymer is 0.916g / cm 3 , the density of LMDPE is 0.90g / cm 3 . Adhesive layer D and adhesive layer E: 28kg of EVA with a density of 0.95g / cm 3 .

[0027] Other methods and structures are the same as in Embodiment 1.

Embodiment 3

[0029] First prepare the raw materials of each layer, core layer B: 98kg of VDC-MA copolymer and 2kg of epoxidized soybean oil. Top layer A: 100 kg of ethylene-EMAA copolymer. Heat seal layer C: 100kg of ethylene-octene-1 copolymer, the density of ethylene-octene-1 copolymer is 0.918g / cm 3 . Adhesive layer D and adhesive layer E: 12 kg of maleic anhydride-modified ethylene polymer.

[0030] Other methods and structures are the same as in Embodiment 1.

[0031]After testing, the main performance indicators of the heat-shrinkable film obtained by adopting the technical solution of the present invention are shown in Table 1.

[0032] Table 1

[0033] Test items

Example 1

Example 2

Example 3

Longitudinal and transverse tensile strength

51MPa

55MPa

52MPa

[0034] Test items

Example 1

Example 2

Example 3

80%

82%

85%

Longitudinal and transverse elongation at break...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com